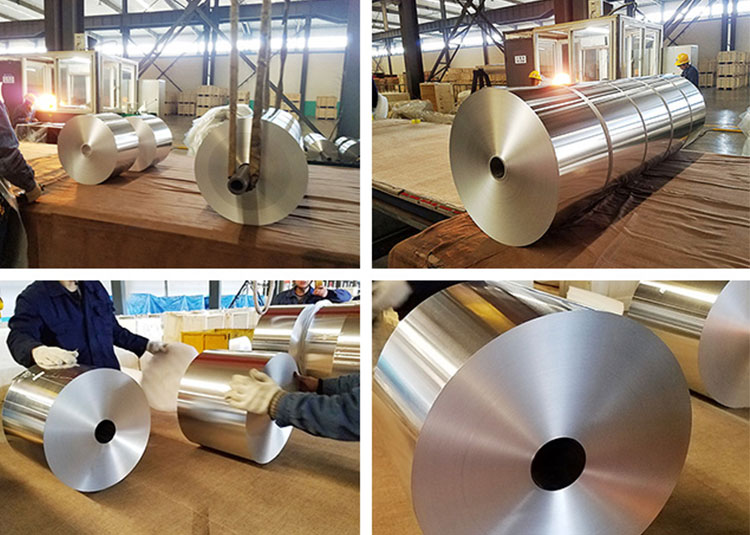

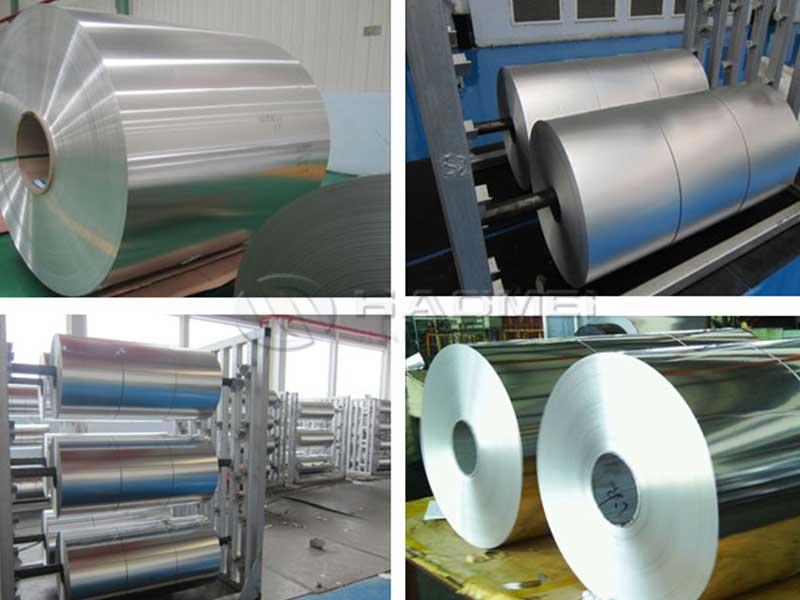

Alloy 8011 H24 Aluminum Foil Jumbo Roll 38 Microns

In the modern technological landscape, specialized materials are critical in ensuring functionality and consistency in production processes and end products. Among those high-demand materials, Alloy 8011 H24 Aluminum Foil Jumbo Roll at 38 microns stands out as an indispensable player across various industries. Delving into the nuanced features and versatile applications of this aluminum alloy underscores its role in cutting-edge advancements and practical utility.

Unpacking Alloy 8011 H24

At its core, Alloy 8011 is distinguished by its unique resistive qualities to numerous physical and corrosive stresses. Composed primarily of 95% aluminum, it seamlessly integrates minimal elements like iron and silicon, which amplify its structural integrity while retaining a lightweight feel. The combination of these components, specifically in the H24 temper, provides the foil with rolling constraints that produce high-yield strength, essential in handling during production and subsequent movement across long supply chains.

Working with Alloy 8011 H24 aluminum foil jumbo rolls, specifically the 38-micron variety, is a daily reality for me. The H24 temper is – it offers a balance between strength and formability that's crucial for our various applications. We see it used extensively in flexible packaging, where its excellent barrier properties against moisture and oxygen are vital. While the 38-micron thickness seems thin, the jumbo roll format allows for efficient processing on our high-speed converting lines, minimizing downtime and maximizing output. One of the biggest challenges is maintaining consistent gauge across such a massive roll; even minor variations can impact the final product quality and necessitate adjustments during the slitting and rewinding processes.

Personally, I find the precision involved in handling these jumbo rolls fascinating. From the initial inspection for surface imperfections and gauge uniformity to the intricate adjustments required on the converting equipment, there's a constant interplay of human skill and sophisticated machinery. A tiny flaw at the beginning of the line can ripple through the entire process, highlighting the need for meticulous attention to detail at every stage. Seeing a flawlessly converted roll of 38-micron 8011 H24 – the result of a seamless production run – is a gratifying reminder of the collective effort and technical expertise that goes into each product. The inherent flexibility of the foil, while beneficial, also demands careful handling to avoid wrinkles or damage that could lead to scrap

Being 38 microns thick offers an optimal thickness that harmonizes flexibility and durability. This trade-off marks a happy medium: sturdy enough to avoid tearing during general handling but pliable to adapt to product shaping. Optical clarity enhances the immediate visual appeal making foil packaging enticing and showcasing ģthe enclosed goods effectively.

Features and Benefits

1. Exceptional Barrier Properties: One of the most notable aspects of Alloy 8011 H24 is its remarkably low permeability to moisture and gases. This barrier functionality effectively preserves the integrity and longevity of food products, making it a preferred solution for food-grade packaging. Foods stored in this type of foil are less susceptible to oxidation and spoilage, benefiting both manufacturers and consumers.

2. Heat Resistance and Stability: The thermal insulation properties of Alloy 8011 H24 are a particular advantage. Competitively utilizing both heating and cooling processes demonstrates the alloy's versatility; it emits minimal heat during extended exposure, helping maintain favorable temperatures for catered events or similar settings.

3. Potent Source for Customization: Comparative anodization allows Alloy 8011 H24 to be readily printed or dyed, leading to compelling branding options. Whether for promotional designs or simple date marking, aluminum foil can display myriad inks and images due to its suitable surface for state-of-the-art printing techniques.

4. Safety and Environmental Considerations: Built from recyclable materials and featuring non-toxic characteristics, Alloy 8011 H24 almost by definition plans an integral role in green initiatives promoting eco-friendly packaging solutions—a significant factor, especially as consumer trends lean towards sustainability.

Varied Applications

-

Food Packaging: Serving and storage of meals, from takeaways to supermarkets, utilizes Alloy 8011 H24 aluminum foil. Businesses rely not only on the enhanced preservation but also the visual aspects that exhibit product freshness in stores and showcases impeccably.

-

Pharmaceutical Industry: For medication packaging, the tamper-proof and moisture-expelling aspects safeguard pharmaceuticals against external conditions, accommodating far-reaching transit to various destinations without compromising product efficacy.

-

Cosmetic Products: Venturing beyond the food sphere, Alloy 8011 H24 is now initial responsible for external cosmetic containers, offering secure coverage for creams and similar products sensitive to their immediate environments.

-

Flexible Industrial Uses: Built-to-index construction facilitates unique industries that serve products in stable clips, clean mantel arrangements, or convenient rolls for numerous development tasks—the vast diversity in operational specifications becomes apparent, accommodated quickly by 38 microns.

https://www.al-alloy.com/a/alloy-8011-h24-aluminum-foil-jumbo-roll-38-microns.html