5083 h111 h321 aluminum alloy sheet plate for marine

Discover the features and applications of 5083 H111 and H321 aluminum alloy sheets and plates, ideal for marine environments. Learn how these materials ensure durability, strength, and resistance against the elements.

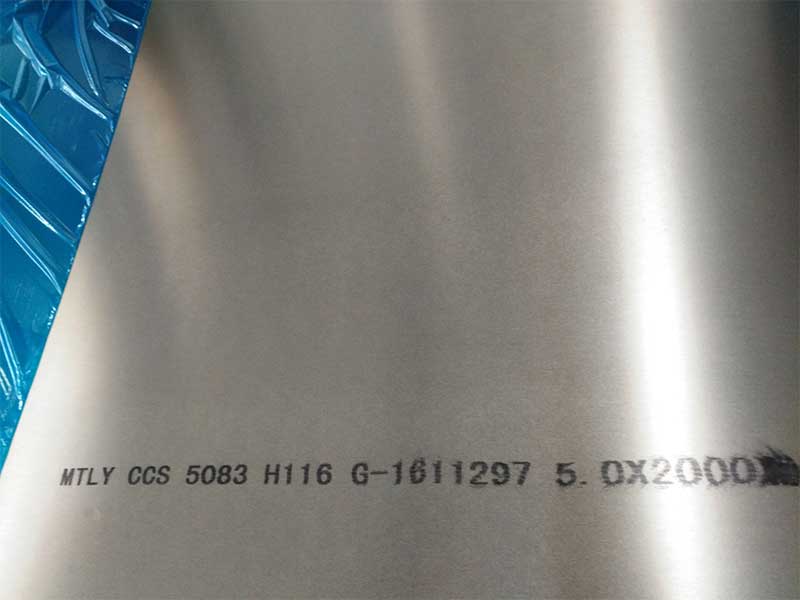

5083 H111 and H321 Aluminum Alloy Sheet Plate for Marine Applications

When it comes to marine applications, the choice of materials is critical to ensuring safety, longevity, and performance. Among the leading materials used in the maritime industry are aluminum alloys, with the 5083 alloy specifically attracting attention for its superior characteristics. Within this category, the H111 and H321 temper designations of the 5083 aluminum alloy sheet and plate stand out for their extraordinary properties and effectiveness in various marine environments.

Features of 5083 H111 and H321 Aluminum Alloy

-

Corrosion Resistance: One of the signature features of 5083 aluminum alloy is its exceptional resistance to corrosion, making it an optimal choice for marine environments. This high resistance is particularly crucial since vessels are frequently exposed to saline water environments. Both the H111 and H321 temper types maintain this critical property, minimizing maintenance requirements and prolonging the lifespan of marine structures.

-

High Strength and Ductility: The 5083 aluminum alloy showcases excellent mechanical properties, ensuring high strength while remaining relatively lightweight. This combination contributes to increased vessel efficiency, allowing for a stronger yet lighter construction. The H111 temper offers good workability, thereby facilitating fabrication. On the other hand, H321 is not only strong but also demonstrates improved toughness and would be ideal for components in harsh marine conditions.

-

Weldability: When working on complex marine construction projects, the weldability of materials cannot be overlooked. The welding characteristics of the 5083 H111 and H321 alloys enable smooth integration into existing structures without compromising integrity. This is particularly essential when constructing or repairing boats, ships, and other structures where the reliability of welded joints is vital.

-

Brilliant Anodizing Properties: An inbuilt benefit of using the 5083 alloy is its ability to undergo anodization effectively, which can enhance its lifespan by providing additional protection against the environment. Anodized surfaces not only look appealing but also further boost the corrosion-resistant properties, allowing structures to withstand the rigors of the sea.

Applications of 5083 H111 and H321 Aluminum Alloy Sheets and Plates

The employment of 5083 H111 and H321 aluminum alloy sheets and plates is widespread in marine industries, adapting flawlessly into various applications:

-

Boat Hulls and Superstructures: Seeking lighter boat designs without compromising strength, fabricators turn to 5083 aluminum alloy sheets for the production of hulls. Due to their corrosion resistance, H111 and H321 grades provide robustness to tackle harsh sea conditions.

-

Shipbuilding: Shipping line industries favor the usage of this alloy when constructing various installations, including decks, wall structures, and even ballast tanks. The weldability and high strength coupled with effective paint finishing make it ideal for designing efficient and appealing vessels.

-

Marine Equipment and Components: Essential marine equipment such as cranes, fasteners, and hatches derive significant advantages from these aluminum sheets and plates. Their resistance to rust and

-

Yachts and Leisure Boats: In the leisure boating sector, the visual appeal of aluminium is appreciated along with its favorable performance in strength-to-weight considerations. Boats designed for comfort, like yachts, gets enhanced features through the use of lightweight and strong 5083 aluminum parts which are easy to maintain.

https://www.al-alloy.com/a/5083-h111-h321-aluminum-alloy-sheet-plate-for-marine.html