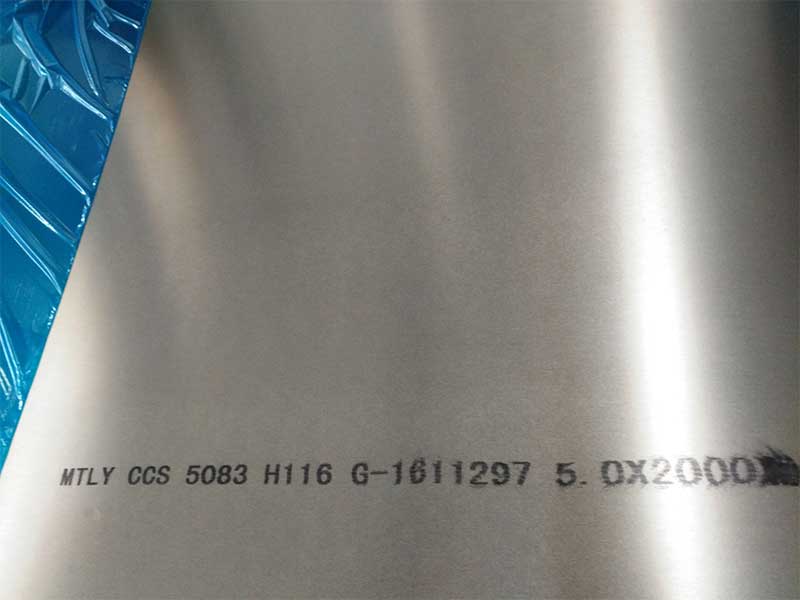

5083 H16 Marine Grade Aluminum Sheet

In the intricate world of materials science, aluminum alloys play a pivotal role, particularly in domains where durability and resistance meet functional aesthetic. Among these alloys, 5083 H16 marine grade aluminum sheet stands out for its formidable combination of strength, corrosive resistance, and weight efficiency.

5083 H16 Alloy

Composition and Characteristics

At its core, the 5083 alloy primarily encompasses aluminum, magnesium, and manganese. This particular formulation guarantees high strength while minimizing weight—critical considerations in marine applications. The "H16" temper denotes a strain-hardened state that provides enhanced durability. This means that while it's relatively lightweight, the sheet has been mechanically worked to achieve significant superior tensile properties.

5083 H16 is renowned for its ability to withstand extreme environments. It maintains structural integrity even in tough marine conditions, withstanding the relentless forces of seawater. Resistant to both pitting and generalized corrosion, this alloy is a preferred option not just above water but for hull structures.

Marine Applications and Relevance

Hull Structures and Shipbuilding

One of the primary avenues for 5083 H16 aluminum is in shipbuilding. Marine engineers routinely choose it for building boat hulls and superstructures, capitalizing on its strength-to-weight ratio. When designing vessels—whether yachts, workboats, or large commercial ships—fuel efficiency is integral. A lighter hull ensures lower fuel consumption, leading to financial savings over time.

Moreover, components such as bulkheads and deck plates also benefit significantly. These structural elements must withstand both the pressures inside and outside, regardless of their exposure to fluctuating water levels and wildlife. The inherent resistance to corrosion in 5083 H16 avoids the extensive maintenance and replacement cycles older materials require—saving cost and time for ship operators.

Tenders and Ferries

Whether increasing passenger capacity in public transportation ferries or crafting marine sports tenders, using 5083 H16 delivers material that resists denting and remains operational under physical stress from rip currents. Famous brands in luxury yacht manufacture specify it due to aesthetic flexibility and durability, allowing designers an expansive canvas for innovation.

Technical Triumph

Fabrication and Processing

Once you understand the relevant applications, it’s essential to explore the processing capabilities of 5083 H16. Its excellent weldability makes it a favorite in fabrication while contributing to smooth textures. It can be readily shaped through bending, cutting, and forming technologies—ensuring that ingenious design ideas don’t seriously challenge what is physically feasible.

The elevated bonding characteristics mean that joining techniques—fusion welding or adhesive bonding—perform exceptionally well, creating interactions within seams that support enhanced structural reliability. Such versatility allows marine architects a breadth of design possibilities.

Consideration with thermal management is also necessary since high-performance marine vehicles often operate in heated situations. The high-performance nature of the material reflects this, allowing rapid heat dissipation that contributes further to onboard safety and efficiency.

Innovative Journey: Events Beyond the Horizon

Though we have detailed sturdy groundwork applications for this material, l

https://www.al-alloy.com/a/5083-h16-marine-grade-aluminum-sheet.html