1100 1200 1060 1070 Polished Aluminum

When considering polished aluminum, there's one thought that often glimmers like the metal itself: the alloy's selection can greatly influence not only the aesthetics but also performance and application. Delving into the choices of 1100, 1200, 1060, and 1070 alloys, you'll uncover a spectrum of qualities—from crafting stunning decorative items to engineering resilient components. Each alloy boasts unique characteristics that are more than just numbers; they reflect capabilities intricately intertwined with the developmental and practical artwork of aluminum applications.

Unblemished Beauty of 1100 Aluminum

The 1100 alloy is akin to the perfectly presented appetizer at a Michelin-star restaurant: whatever splendid creation follows doesn’t overpower its perfection, but instead complements it. Known for its superior corrosion resistance and high thermal conductivity, 1100 polished aluminum shines with bright, mirror-like finishes that are perfect for decorative and functional elements.

Working with 1100, 1200, 1060, and 1070 polished aluminum sheet daily, I've noticed subtle but significant differences beyond their shared softness and workability. The 1100, our workhorse, is incredibly consistent in its properties, making it ideal for large-scale projects where uniformity is paramount. However, its slightly lower strength compared to 1200 can be a concern in applications demanding higher durability. We find the 1060 excels in deep drawing applications due to its superior formability, while the 1070, though similar, sometimes exhibits minor variations in surface finish post-polishing, requiring extra attention during quality control. These differences often dictate which alloy is most cost-effective for a given order; a seemingly small variation in formability can drastically impact production time and scrap rate.

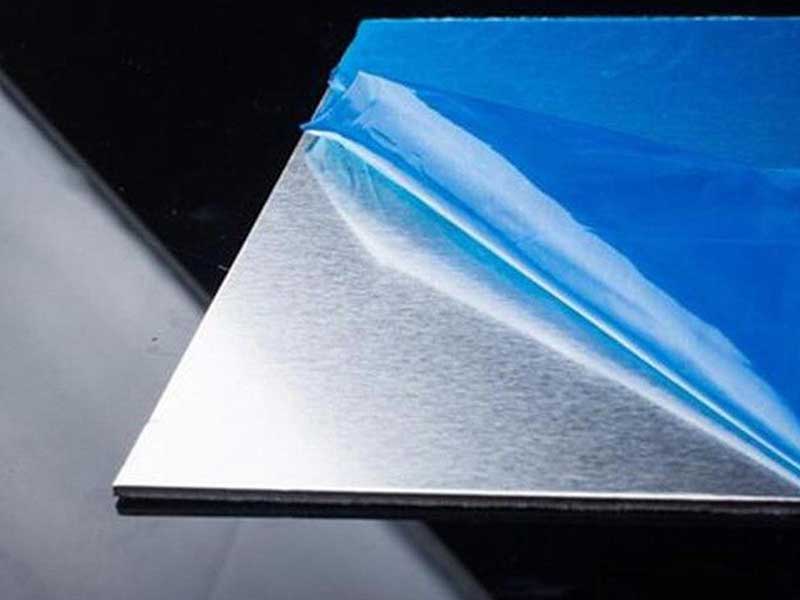

Beyond the technical specifications, the sheer aesthetic of these polished alloys is a source of constant fascination. The reflective surface, once flawlessly achieved through our multi-stage polishing process, reveals the meticulous care taken during manufacturing. A minor imperfection, even a microscopic scratch, stands out dramatically against the mirror-like sheen, highlighting the high standards we strive for. I find myself frequently appreciating the contrast between the material’s inherent softness and its surprisingly resistant polished surface; a testament to both the alloy's properties and the skill of our team. This

This alloy also exemplifies remarkable ductility, making it an excellent choice for intricate designs and crafts. Its commercial applications generally include decorative trim, nameplates, and cooking equipment, where a stunning visual appeal is required without compromising utility. Selecting 1100 is selecting pristine elegance combined with a short-handed history of aluminum’s vulnerability to the elements.

Clarity of 1200 Aluminum

Beneath its similarity to 1100 rests 1200 aluminum, which carries slightly refined properties suited for specific needs. Its advantages, such as excellent reflectivity and facing minimal scale buildup at higher temperatures, make it ideal in high-barrier packaging applications like soft drink cans, and rising to prominence in simple conveyance mechanisms.

Choosing 1200 polished aluminum enhances product longevity without detracting from visual countenance. This alloy is strategically utilized in any setting where “simple elegance” becomes a centering idea—defining aesthetics with a practical purpose.

Resilient and Reliable: 1060 Aluminum

The 1060 alloy sways into the discussion with an appealing overview—it embodies a balance of cost-effectiveness, high ductility, and excellent thermal properties. It perpetuates a hallmark smooth brightness, leading to its widespread use in applications requiring high sustainability along with bright visual adaptability.

1060 polished aluminum often finds itself in power transformers and electrical components, smoothly sustaining efficiency in operations. Its versatility is further amplified in architecture and signage, reflecting the surrounding world picturesquely while standing resilient against fading and wear.

Sheen of Perfection: 1070 Aluminum

When dictating the apex of aluminum’s polished elegance, 1070 emerges alarmingly close—one might say fully painted in lush refinement. Predominately acknowledged for its extraordinary or rather unmatched purity (99.7%), this alloy shines intensely, embodying works of art cherished by designers all over the globe.

Ideal for close encounters with the eye (~we think~ sip), instantiated applications span through decorative features, food and chemical handling due to its lack of contamination risks. The sheer brilliance of polished 1070 stands apart, alongside its staggering workability taken for granted at times. Who knew Banquet tables could reflect splendor down to an element?

Interconnection and Detailed Considerations

While individual choice characterizes each aluminum alloy, acknowledging their interconnections exemplifies the intrinsic wisdom for a more holistic perspective. Price distinctions reflect numerical variance—as do their corresponding mechanical characteristics: 1100 caters to designers' dreams whereas 1070 fixes precision-like excellence for specialized occasions.

For given projects and venues, intricacies can guide away from mere comparisons and into selectivity celebrating detail. That shiny, smug exterior speaks to everyday experiences just as much as high-sphere endeavors showcase part of quiet statements echoed within unique artistry thresholds.

For contractors, artisans, and designers alike seeking tailored applications, favoring polished aluminum to awaken brilliance demands approaching each encounter with deliberate insights—it translates through variance and ends with promise. Meticulously matching needs alongside the tailored charm of either 1100, 1200, 1060, or 1070 creates radiance for future use always shining through!

https://www.al-alloy.com/a/1100-1200-1060-1070-polished-aluminum.html