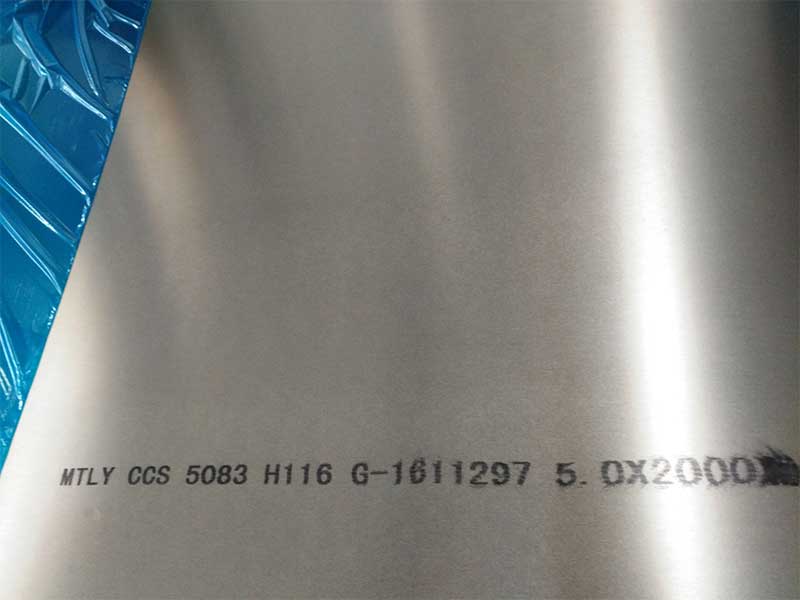

5083 H116 Aluminum Plate for Shipbuilding

When it comes to shipbuilding, material selection can be the difference between a floating vessel enduring the harshest sea conditions or one that succumbs to the environment's merciless grip. Among the myriad materials available today, the 5083 H116 aluminum plate has emerged as a benchmark for naval architects and builders alike, known for its stellar composition and functional capabilities.

Unique Composition and Mechanical Properties

5083 aluminum is a marine-grade alloy comprising magnesium and manganese, which imparts substantial corrosion resistance while enhancing weldability. The H116 temper is pivotal, signifying that the plate is certified for good strength properties and enhanced stress-raising approaches characteristically demanded in shipbuilding.

Working with 5083 H116 aluminum plate in shipbuilding presents a unique set of challenges and rewards. Its excellent corrosion resistance in marine environments is a primary draw, particularly in saltwater applications where pitting and crevice corrosion are significant concerns. However, the H116 temper, while offering good strength, necessitates careful handling during fabrication. We've found that pre-heating before welding is absolutely crucial to prevent cracking, and even then, proper weld procedures and post-weld heat treatments are vital for ensuring structural integrity. The material's higher cost compared to other aluminum alloys is often justified by its extended lifespan and reduced maintenance needs, making it a cost-effective choice in the long run, especially considering the high costs associated with ship repairs or replacements.

Beyond the technical aspects, the specific application within the vessel is paramount. We’ve seen instances where specifying the appropriate thickness for hull plating or deck structures is critical. Over-specifying leads to unnecessary weight and cost increases, while under-specifying risks compromising structural integrity. Close collaboration with the design engineers is to optimizing material usage and ensuring the final product meets all required safety and performance standards. This includes not only considering the mechanical properties but also the impact of the marine environment on the long-term performance of the 5083 H116 plate, predicting potential degradation and factoring in necessary safety margins.

Mechanical Properties of 5083 H116 Aluminum Plate Include:

- Yield Strength: 260 MPa (Approx.)

- Ultimate Strength: 310 MPa (Approx.)

- Elongation: 12% in 50mm

- Density: 2.66 g/cm³

These attributes specifically denote that the 5083 H116 plate uniquely possesses the requisite mechanical strength to withstand the vibrations and dynamic stresses encountered during maritime navigation, making it exceptionally suitable for structural components.

Superior Corrosion Resistance

One of the encompassing advantages of 5083 H116 aluminum plate lies in its corrosion resistance in marine environments. Shipbuilding materials are invariably subject to saltwater exposure, increasing the potential for fatigue and corrosion. 5083 h116 boasts excellent performance in sea water conditions due to its non-pitting qualities, thereby prolonging the service life of vessels. Employing high-purity magnesium — up to 4.5% — downward reduces the likelihood of corrosion montages.

Applications in Shipbuilding

The end uses of 5083 H116 aluminum plate extend to several critical components in shipbuilding. Below are some of the notable applications:

-

Hull Structures: H116 plates are essential in crafting robust hull sections that resist hydrostatic and hydrodynamic forces when ships navigate various water conditions. Its lightweight properties also contribute to optimized fuel efficiency while enabling substantial payload capacities.

-

Deck Houses: Deckhouses constructed with 5083 H116 benefit greatly from both its aesthetic qualities and non-combustible makeup, making them an ideal element in passenger vessels and commercial crafts, improving passenger safety and comfort level.

-

Bulkheads & Panelling: Installed in both bulkheads and side panels, the lightweight yet highly durable properties allow for quick assembly and installation without sacrificing the structural integrity needed in marine habitats.

-

Grating and Railing System: For safety and mobility, 5083 H116 plates are routinely fashioned into grating and railings aboard ships. Adding an extra layer of durability, their anti-slip surfaces keep crews safe while providing comprehensive through-life inspections.

The Fabrication and Wiggle of 5083 H116

Professionals working with high-quality aluminum plates like the 5083 H116 appreciate their easy machining and straightforward fabrication. This alloy has obvious weldability that performs excellently when subjected to the various progressive methods employed in shipbuilding. Commonly welded via MIG or TIG methods, it ensures seamless assembly while maintaining marketing characteristics.

These plates support eventual finish applications independent of their structural stability; through powder coating or anodizing, craftsmen can enhance the alloy's appeal designed for specialized marine themes.

https://www.al-alloy.com/a/5083-h116-aluminum-plate-for-shipbuilding.html