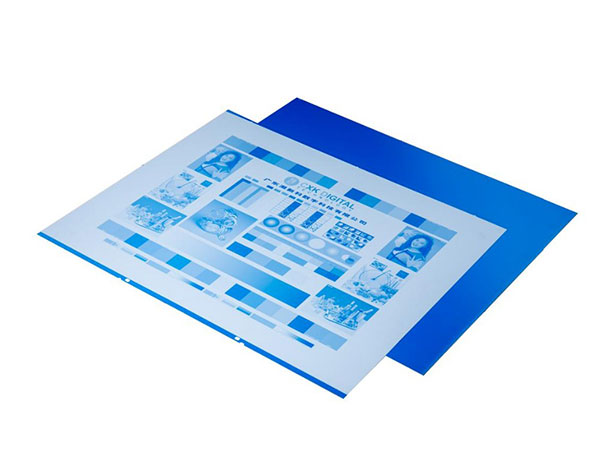

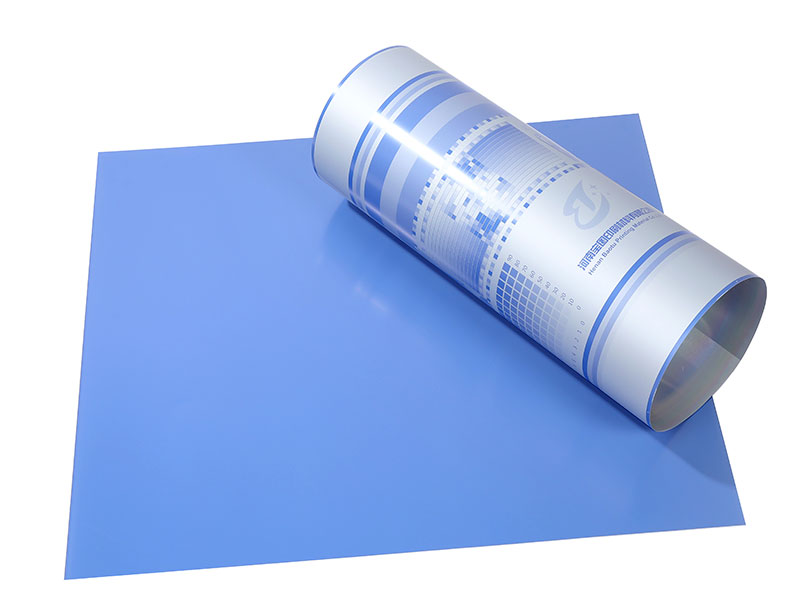

Aluminum offset CTP Printing plates

Aluminum Offset CTP Printing Plates: Features and Applications

In the fast-evolving landscape of the printing industry, technology continues to create opportunities for enhancing productivity and improving print quality. One of the pivotal developments in modern printing processes is the aluminum offset Computer-to-Plate (CTP) printing plates. These aluminum plates have emerged as the preferred choice for many commercial printers, offering specific features and broad applicability that redefine printing precision and efficiency.

Features of Aluminum Offset CTP Printing Plates

-

High-quality Printing: Aluminum CTP plates boast superior print quality, facilitating exceptionally sharp and clear images. This precision ensures that every detail captured in the design results in vibrant real-world print material.

-

Light Sensitivity: These plates are specially engineered to establish a strong bond under light exposure. The tightly controlled emulsions used with CTP models efficiently respond to lasers, enabling precise image exposure and producing defined halftones and tonal gradations.

-

Durability and Longevity: Aluminum, by its nature, is a much more durable material compared to several alternatives. Aluminum offset CTP plates resist deformation and wear, contributing to prolonged lifespan, even under demanding printing environments. Their robustness helps maintain an exemplary standard throughout multiple print runs.

-

Environmentally Friendly: Most modern aluminum offset plates utilize a chemistry-free chemistry. This means that they greatly reduce the need for harsh processing chemicals, aligning with the growing demand for eco-friendly printing practices and substantially easing environmental footprints.

-

Highly Automated Processes: In today’s high-speed printing operations, automation represents a critical demand for efficiency. Aluminum offset CTP plates are specifically designed to integrate flawlessly into automated workflows, facilitating seamless production and reducing labor costs.

-

Cost-Effectiveness: While artistic quality and raw aesthetics are crucial, the economic impact shouldn’t be overlooked. While additional investments are necessary for purchasing CTP equipment, the efficiency and reduction in waste lead to substantial long-term savings.

Wide Range of Applications

Aluminum offset CTP communication plates find ample utility across various sectors of the printing industry:

-

Commercial Printing: Newspapers, brochures, catalogs, and magazines regularly depend on this application. The combination of easy reproduction and a crisp finish positions these plates as the best choice for vibrant, high-volume production runs.

-

Packaging Industries: With rising demands in packaging design and techniques, such as flexible and rigid packaging, aluminum offset CTP plates' precision makes them push boundaries of creativity and clarity in the consumer goods sector.

-

Specialty and Artistic Printing: For high-end projects requiring custom design work or unique finishes, aluminum plates deliver stunning outcomes while fulfilling designs nestled deep in properties specificational management.

-

Label and Stickers Printing: High precision and fast turnaround make these plates excellent for producing high-quality labels and stickers required by various industries, such as food, beverage, and retail.

-

Book Publishing: Achieving consistent branding and design often elevates a printed book's perceived value in consumer senses. Print runs in books represent high variability in designs and coverage conditions where CTP efficiently meets multiple intricate needs.

https://www.al-alloy.com/a/aluminum-offset-ctp-printing-plates.html