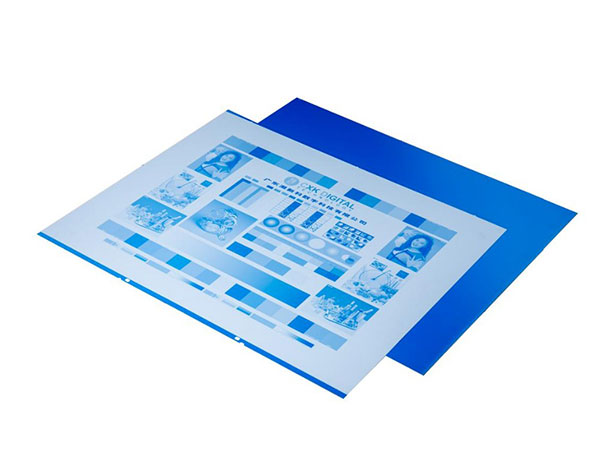

| Application | High quality commercial and newspaper printing |

| Spectral Sensitivity | 320-450nm |

| Resolution | 2-99% |

| Thickness | 0.15-0.30mm |

| Specification | 0.15mm 100PCS/box; 0.30mm 50PCS. |

| Developer Temperature | 23+/-2 Degree |

| Laser Energy Required | 80-180mj/Cm2 |

| HS Code | 3701302 |

| Transport Package | Export Standard Seaworthy Package |

Process-less Thermal CTP Plates are a type of printing plate that does not require chemical development after exposure. These plates are designed to be ready for mounting on the printing press immediately following exposure, thanks to a special coating that enables the plate to be developed using the ink and fountain solution during the initial stages of printing. This innovation simplifies the prepress workflow, reducing time, labor, and waste associated with traditional plate processing.

Composition and Structure

The structure of a process-less thermal CTP plate typically includes:

Aluminum Base: Providing a robust and stable foundation for the plate, ensuring consistent performance during the printing process.

Thermal-Sensitive Coating: This advanced coating is sensitive to thermal energy from laser exposure, allowing for precise imaging. Unlike traditional plates, this coating undergoes a chemical transformation during exposure, preparing it for direct use on the press without further processing.

How Process-less Thermal CTP Plates Work

The operation of process-less thermal CTP plates streamlines the traditional plate-making workflow:

Laser Imaging: The plate is exposed to a thermal laser that writes the digital image directly onto the sensitive coating, creating precise and detailed image areas.

On-Press Development: Once the plate is mounted on the printing press, the ink and fountain solution interact with the coating. This process removes non-image areas, facilitating immediate printing without the need for an offline processing step.

Printing: The plate is used for printing in the same way as any other offset plate, benefiting from the same level of precision and detail provided by advanced digital imaging techniques.

Benefits of Process-less Thermal CTP Plates

Environmental Impact: By eliminating chemical processing and water usage, process-less plates significantly reduce the environmental footprint of the printing operation.

Time and Cost Efficiency: Without the need for developing chemicals and the associated equipment, printers save on both time and costs, improving overall operational efficiency.

Simplified Workflow: The reduction of prepress steps enhances workflow speed and reduces the potential for error, leading to faster turnaround times and increased productivity.

High-Quality Output: These plates deliver sharp, high-resolution prints, meeting the high standards expected in commercial and professional printing applications.

Applications

Commercial Printing: Ideal for brochures, catalogs, and marketing materials, where quick turnarounds and high quality are essential.

Newspaper Production: Offers advantages in speed and cost, crucial for daily publications with tight deadlines.

Packaging: Provides consistent and high-quality results that are critical in meeting brand standards in packaging design and print.