Printing plate aluminum thermal ctp plate

The world of printing has undergone a remarkable transformation with the advent of Computer-to-Plate (CTP) technology. Among the players in CTP systems, aluminum thermal CTP plates is know as indispensable tools that enhance efficiency, precision, and quality in the printing process. Known for their durability and performance, these plates have revolutionized the ways printers approach pre-press operations.

Aluminum Thermal CTP Plates

Aluminum thermal CTP plates are specially designed graphic substrates used in offset printing. Unlike traditional methods that rely on film output, CTP technology allows for direct imaging onto the printing plate via a laser, enabling highly accurate representations of digital files. These plates boast several features that make them suitable for the contemporary printing industry:

One of the most critical aspects of producing high-quality Aluminium CTP plates lies in the meticulous control of the thermal imaging process. Slight variations in laser power, exposure time, or even the ambient temperature within the processing unit can dramatically impact the resulting plate's quality. For instance, insufficient laser power leads to weak image areas resulting in poor ink transfer and print defects. Conversely, excessive power can cause plate damage or unwanted plate expansion, affecting registration and ultimately impacting the print run. Therefore, routine calibration and preventative maintenance of our CTP equipment, coupled with rigorous quality control checks at each stage—from plate preparation to final imaging—are crucial for consistent, high-resolution output. We've found that regularly analyzing the plate's surface roughness and chemical composition using specialized tools provides invaluable data for fine-tuning the process parameters.

Beyond the technical aspects, managing the aluminum plate's storage and handling is often overlooked but equally vital. Humidity and temperature fluctuations can negatively affect the plate's surface, leading to oxidation or inconsistencies in the image development process. We've implemented strict environmental controls in our storage area and developed specialized handling procedures to minimize potential damage. Even seemingly minor scratches or fingerprints can significantly compromise the printing quality. This meticulous approach, combining advanced technology with careful attention to detail in all aspects of production, is what allows us to consistently deliver high-performing Aluminium CTP plates to our clients, meeting their demanding print quality expectations.

-

Material Composition: Aluminum is the metal of choice due to its lightweight yet high-strength properties. The plates typically have a thin polymer coating that offers a unique surface texture, allowing for superior ink adhesion and consistent performance across print runs.

-

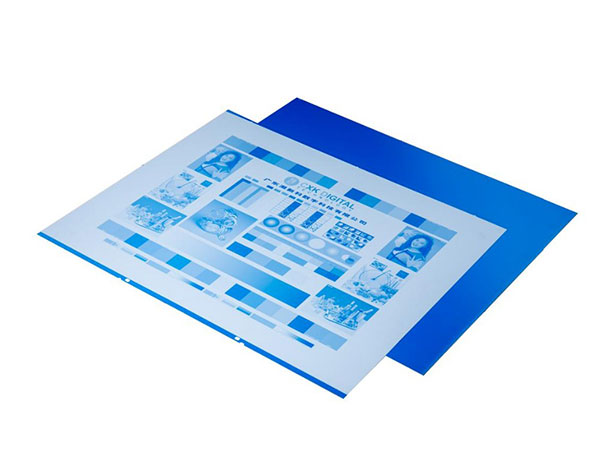

Thermal Sensitivity: As the name suggests, thermal CTP plates are sensitive to heat. Advanced laser technologies expose these plates to specific wavelengths, refining compositions that create differing toughened and non-toughened areas, corresponding to the image and non-image regions. This feature fine-tunes the printing quality, ensuring clean edges and vibrant colors.

Unique Functions of Aluminum Thermal CTP Plates

-

Optimized Production Process: One of the most significant transformations introduced by aluminum thermal CTP plates is the optimization of the printing process. Traditional photolithography requires multiple steps, including film development that consumes time and materials. CTP systems streamline these stages, reducing labor costs and expediting turnaround times. As such, print businesses can produce high volumes of work while minimizing wastage.

-

Enhanced Image Quality: The precision of direct imaging culminates in unparalleled image redaction on pressed materials. With a finer resolution and smooth tonal transitions, aluminum thermal CTP plates deliver high-fidelity outputs characteristic of high-quality commercial printing. Therefore, brands can uphold their reputation by showcasing striking visuals that captivate their target audience.

-

Extended Plate Life: Aluminum thermal CTP plates are engineered for strength and longevity—allowing multiple print runs while diminishing wear and tear. This characteristic not only extends the life of the plates but also minimizes the environmental impact found in disposable alternatives. Users experience reduced costs per unit and less frequency of plate change, deepening the operational efficiency of print houses.

Practical Applications in Printing

Aluminum thermal CTP plates cater to a plethora of applications, adapting seamlessly across various industries. Their versatility authorizes printers to tackle diverse market requirements without compromising quality:

-

Commercial Printing: Businesses engaged in product advertisements, packaging, catalogs, and marketing collateral rely on aluminum thermal CTP plates for their excellent resolutions and short lead times.

-

Publication Printing: Journalists, publishers, and creatives recognize the need for consistent, high-quality reproductions of graphics and text. The fine line work achievable with CTP plates elevates publication standards while meeting urgent deadlines.

-

Label and Packaging: The shifting consumer demographics place demand on label and packaging quality—with eye-catching graphics playing a pivotal role. Printing presses utilize aluminum thermal plates to produce distinct branding delivers simplicity and impact.

Technical Advantages

When examining the technical specifications, aluminum thermal CTP plates come with particular benefits that are worth underscoring:

-

Stability in Performance: Aluminum plates can tolerate variable conditions, withstanding the rigors of different climates and workflows without compromising the printing output.

-

Cost-Efficiency: With longer lifespans and reduction in materials utilized in production, these plates effectively lower the total cost of ownership—a primary consideration for print operations growth.

-

Environmentally Conscious Option: With recyclable materials and reductions in waste production, using aluminum thermal CTP plates aligns with the industry's increasing emphasis on sustainability.

https://www.al-alloy.com/a/printing-plate-aluminum-thermal-ctp-plate.html