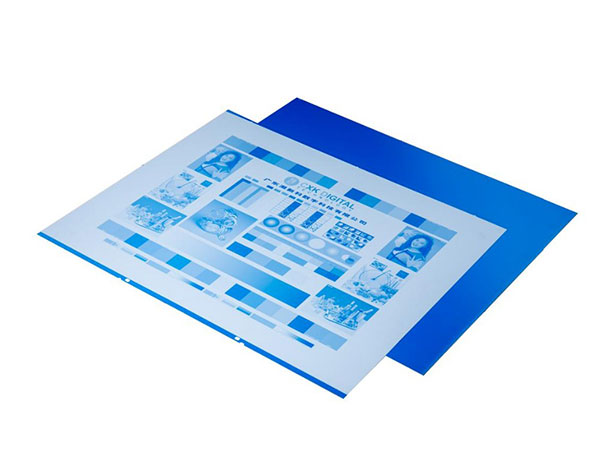

740 x 615 Offset Plate Thermal CTP plates for GTOKord Machine

740 x 615 Offset Plate Thermal CTP Plates for GTOKord Machine: Features and Applications

In today’s fast-paced printing industry, efficiency and quality are key. The emergence of thermal Computer-to-Plate (CTP) technology has revolutionized the way printing plates are developed. Among these innovations are the 740 x 615 Offset Plate Thermal CTP plates, specifically designed for the GTOKord Machine. This unique combination satisfies both the technical demands of printers and the creative aspects that drive unique printed content.

Working with 740 x 615 mm thermal CTP plates for GTOKord machines presents unique challenges compared to other plate sizes and manufacturers. We often see issues stemming from the sheer size of the plate; handling and processing require meticulous care to avoid scratches or warping, especially during the crucial stages of pre-press processing like plate mounting and exposure. The GTOKord machine's specific parameters, particularly its processing speed and pressure settings, are critical; slight deviations can lead to inconsistent image quality, from uneven exposure resulting in light areas or ghosting to increased plate wear and shorter lifespan. We've found that regular preventative maintenance on the GTOKord, including careful cleaning of the rollers and precise calibration of the processing units, is absolutely paramount to maintaining optimal plate performance and minimizing waste.

Our experience indicates that the quality of the aluminum substrate itself significantly impacts the final product. Variations in aluminum purity and thickness can affect the plate's sensitivity to the thermal exposure, leading to inconsistent results. We've had success in minimizing this by rigorously checking the incoming plates for any imperfections and ensuring consistent storage conditions. Furthermore, optimizing the pre-press workflow, including appropriate image sharpening and screening techniques tailored for the GTOKord machine, drastically improves the overall quality and reduces the number of plates requiring remakes due to flaws. This holistic approach, focusing on both the mechanical aspects of the GTOKord and the pre-press preparation, has proven critical in maximizing

What are Thermal CTP Plates?

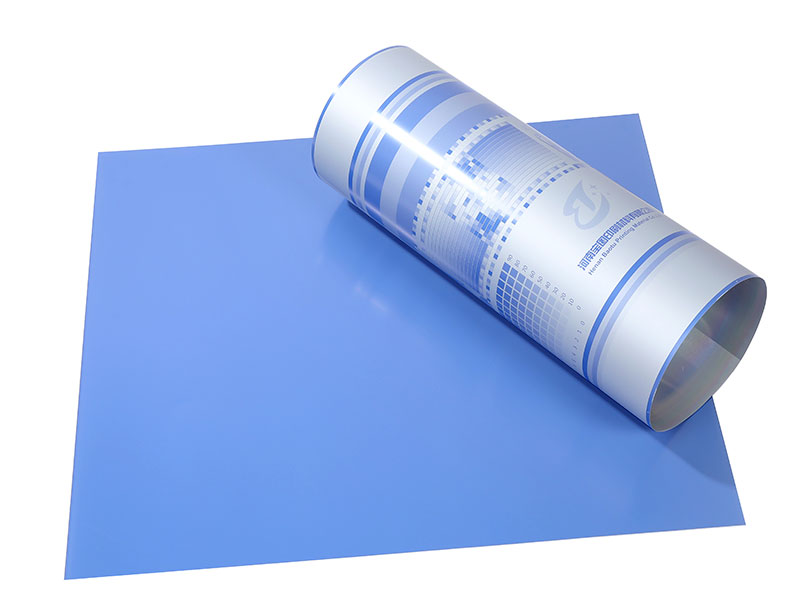

Before delving into their applications and features, it's essential to understand what thermal CTP plates do. Unlike traditional photochemical plates, thermal CTP plates use laser technology to expose a photosensitive layer on the plate. This technology allows for more precise print production, reducing setup times and improving output quality.

Features of 740 x 615 CTP Plates

-

Size Specification: The 740 x 615 size is customized to fit the GTOKord machine—a favorite for both commercial and specialized printing projects. This custom sizing maximizes the machine's efficiency and workflow, minimizing wastage.

-

High-Resolution Imaging: The ability of these plates to capture sharp, high-resolution images means that intricate design elements, tones, and halftones are reproduced with superior accuracy. Challenging designs that might falter on standard plates come to life, fidelity intact.

-

Quick Production Speeds: Due to their design and compatibility with GTOKord machines, these plates are engineered for speed without sacrificing quality. This allows print operations to handle higher volumes with less downtime, particular during demanding printing runs.

-

Durability and Longevity: The thermal plates offer outstanding resilience compared to traditional plates. They show enhanced resistance to wear and tear, providing a longer lifespan and consistent quality across production runs.

-

Eco-Friendliness: A cutting-edge feature of modern thermal CTP plates is their environmentally friendly nature. These plates minimize chemical use typically associated with plate processing, making them an ideal choice for eco-conscious printing services.

Applications in the Industry

The versatility of the 740 x 615 Offset Plate Thermal CTP plates aligns perfectly with various industries:

-

Commercial Printing: For print houses engaged in literature, publications, and marketing materials, the precise detailing provided by these plates greatly enhances the aesthetic qualities of printed materials, creating memorable visuals.

-

Packaging and Labels: Label manufacturers appreciate the vibrant color representation and clarity these plates offer. Operational efficiency means higher output with reduced lead times, allowing them to cater to market trends swiftly.

-

Textile Printing: Finishing textiles require precision for patterns and designs. The unique output capabilities of thermal CTP plates make them invaluable in the textile printing sector, which prizes both detail and speed.

-

Digital and Offset Hybrid Machines: As technology converges toward integrated processes, the ability of GTOKord machines to accommodate unique materials expands their application scope. This flexibility suits digital print environments optimally.

Final Thoughts

The 740 x 615 Offset Plate Thermal CTP plates designed for the GTOKord machine represent a remarkable improvement in printing technology, marrying speed with precision while reducing the environmental footprint. Their broad applications across various sectors set a new standard in printing productivity and quality. Suppliers and print operations adopting this innovative technology stand to gain significantly in customer satisfaction and efficiency.

In an era where attention to detail matters, the introduction of these plates reflects a clear of market needs and an innovative response to usher in a new era of printing. The future of print may well be defined by such advancements, where quality and efficiency converge seamlessly.

https://www.al-alloy.com/a/740-x-615-offset-plate-thermal-ctp-plates-for-gtokord-machine.html