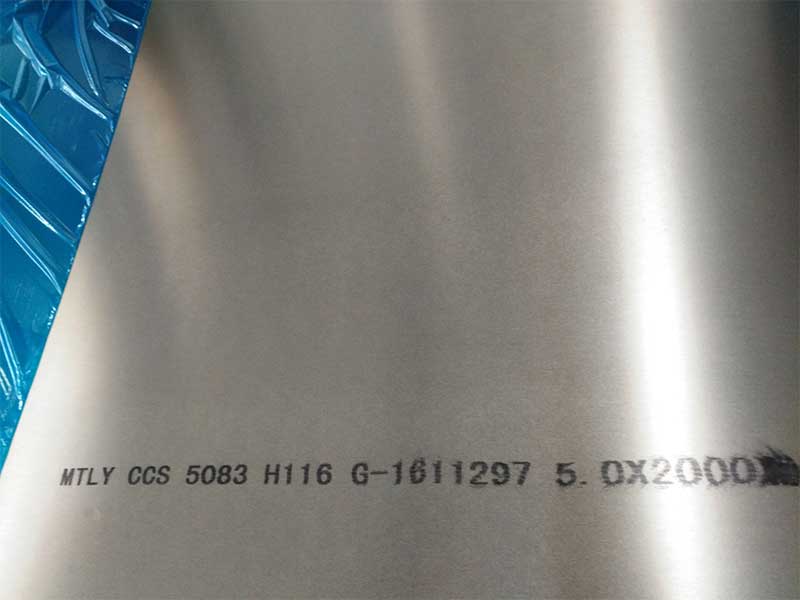

Marine grade aluminum sheet 9mm thick for construction

In the world of construction, the materials we choose not only need to be durable but also serve specific purposes based on the environment in which they will be utilized. Among these materials, 9mm thick marine grade aluminum sheets is know as a formidable option.

The Distinct Features of Marine Grade Aluminum Sheets

1. Robust Resistance to Corrosion: One of the defining features of marine grade aluminum is its remarkable resistance to corrosion. Composed of magnesium and silicon, aluminum alloys specifically engineered for marine applications—such as the 5052 or 5083 grades—demonstrate exceptional durability against saltwater degradation. This makes them ideal for shipbuilding, marine structures, and coastal construction where exposure to harsh environmental elements is a given.

2. Ideal Thickness for Performance: With a thickness of 9mm, these sheets strike a perfect balance between lightweight flexibility and sturdy strength. This property allows for ease of handling and installation, yet ensures that the material can withstand considerable loads or stress without compromising on integrity. Decision-makers in construction often find comfort in knowing that a 9mm thick sheet will deliver the right level of both portability and sturdiness.

3. Excellent Machinability and Fabrication: Marine grade aluminum is inherently adaptable, allowing for easy machining and shaping. From cutting and drilling to bending and welding, these sheets are a contractor's dream for various construction applications. Builders can create custom profiles and parts that cater to unique needs, making aluminum an incredibly versatile material—everything from supports for buildings to detailed architectural designs become feasible.

4. Sustainable and Eco-Friendly: Aluminum is inherently a sustainable material, and marine grade aluminum sheets are no different. They are 100% recyclable without loss of properties, contributing to greener construction practices. Given the rising urgency around sustainability, using marine grade aluminum sheets can help builders reduce their carbon footprint while ensuring high performance in extreme conditions.

Diverse Applications in Construction and Marine Industries

1. Marine Construction:

The primary application of 9mm thick marine grade aluminum sheets can be found in boatyards and shipbuilding. They provide the sturdiness needed for frameworks, hulls, decks, and superstructures, all requiring longevity against salinity and pitting corrosion. Architects and designers working on yachts and marine craft favor aluminum sheets for their combination of strength and lightweight properties, which leads to greater overall efficiency.

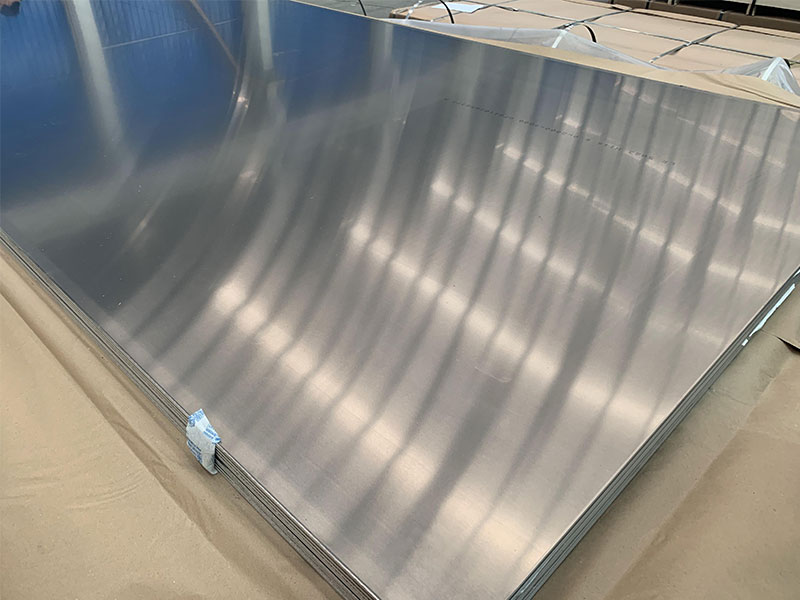

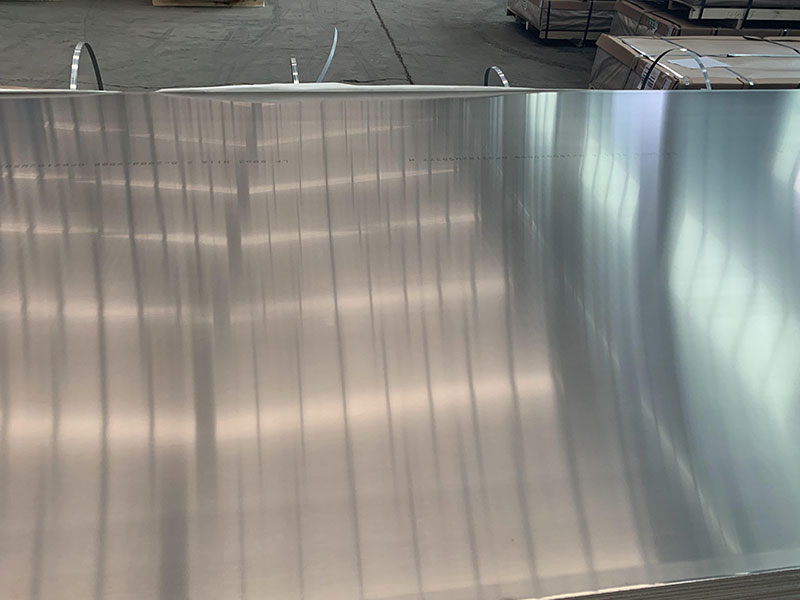

Working with 9mm marine-grade aluminum sheet is a different beast entirely compared to the thinner gauges we typically process. The sheer weight and stiffness present unique challenges in handling and fabrication. We often see it used for demanding applications – things like boat hulls, bridge components, or specialized industrial equipment requiring exceptional corrosion resistance. Its thickness means heavier-duty equipment is needed for cutting and forming – our CNC router struggles sometimes, and we frequently rely on plasma cutting for cleaner edges. The quality control is also far more rigorous; we meticulously check for surface imperfections and test for the specified alloy composition to ensure it meets the stringent marine standards. Witnessing the final product, a robust component ready to withstand harsh environments, is immensely satisfying – it's a testament to the material's strength and the precision of our manufacturing process.

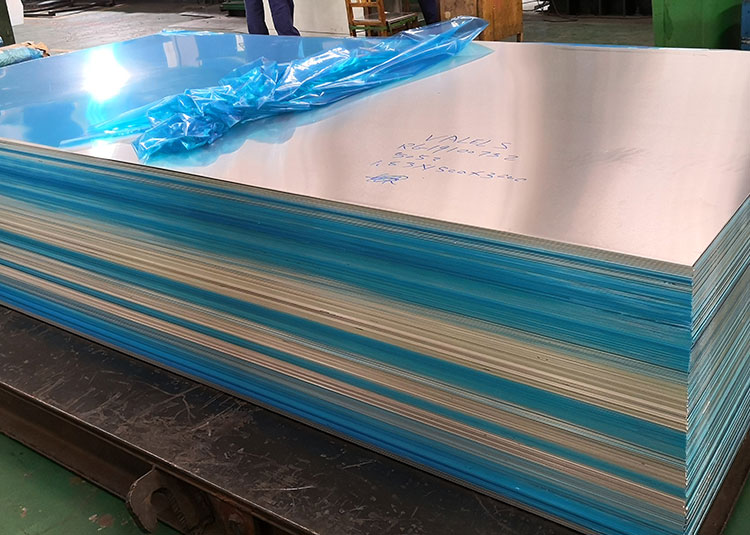

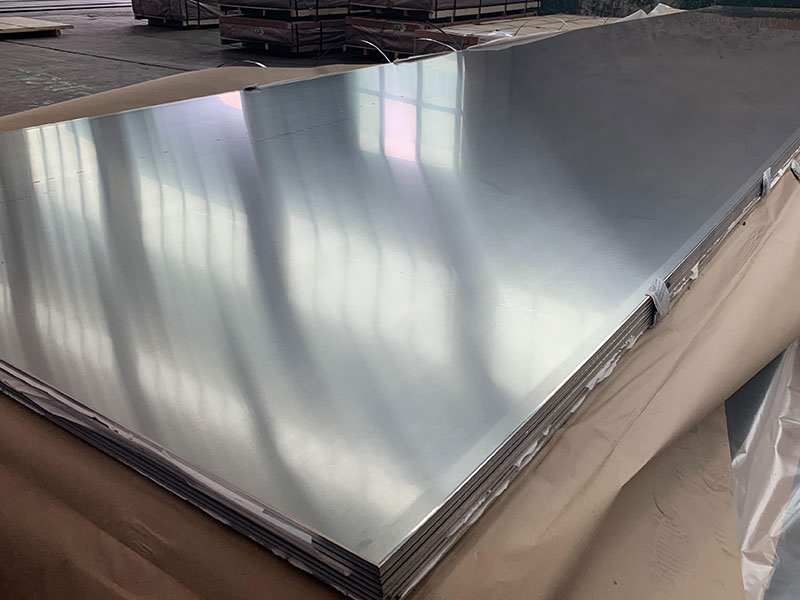

Personally, I find the material fascinating. The way it reflects light, the almost silvery gleam, is quite beautiful, especially after the final polishing. However, I also appreciate the that this beauty masks a serious purpose. This isn't just pretty metal; it's a vital component in infrastructure and equipment designed to last decades in incredibly demanding conditions – salty air, constant vibration, and potentially extreme temperatures. That longevity, that reliability built into every sheet, is what makes working with this material both challenging and rewarding. It's a constant reminder of the crucial role our factory plays in building durable, long-lasting products.

2. Coastal Infrastructure:

In regions around coasts and harbors, where structures face the brunt of wind, waves, and salt spray, the use of marine grade aluminum is invaluable. From walkways and piers to support structures and flood defense systems, these sheets provide security and resilience, ensuring longevity in environments where many materials would fail.

3. Architectural Design:

As designers and builders look to fuse aesthetics with functionality, 9mm thick marine grade aluminum sheets have woven their way into contemporary architecture. They are often used in façades, roofing, and cladding systems due to their modern appeal, allowing intricate designs that are both striking and effective, yet resistant to the weathering effects of sun, salt, and rain.

4. Automotive and Recreational Applications:

Beyond marine use, many resort to these sturdily constructed sheets in automotive thrills like boat trailers, RVs, and off-road vehicles where weight savings intersect with strength. Travelers derive peace of mind knowing their equipment is outfitted with materials engineered for resilience, fortifying their excursions into nature.

https://www.al-alloy.com/a/marine-grade-aluminum-sheet-9mm-thick-for-construction.html