Resolution UV ink accepted CTP Printing Plate for kord and GTO 46

The Advantages of Resolution UV Ink Accepted CTP Printing Plates for Kord and GTO 46

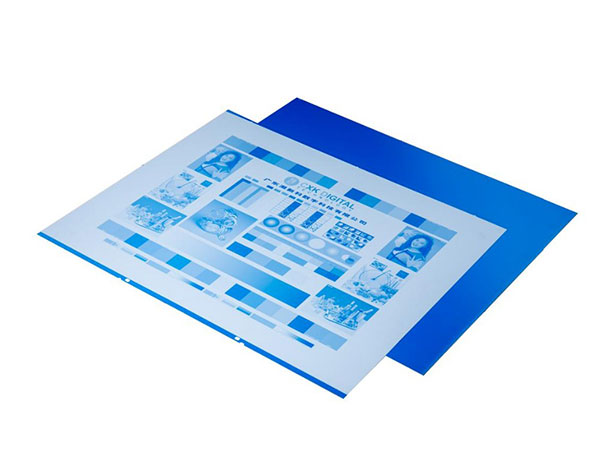

In the constantly evolving landscape of the printing industry, the tools of the trade must adapt to meet the demanding visions of modern design and production. One exemplary innovation is the Resolution UV Ink Accepted CTP Printing Plate tailored specifically for printers using Kord and GTO 46 machines.

Working with Aluminium CTP plates for Kord and GTO 46 presses, particularly concerning resolution and UV ink compatibility, highlights the critical balance between image quality and print longevity. We've found that achieving high resolutions (e.g., >2400 dpi) reliably requires meticulous platemaking processes. This includes precise exposure control to avoid under or over-exposure leading to either weak highlights or clogged details. The type of UV ink plays a significant role; some formulations are more aggressive, potentially leading to plate degradation and shorter lifespan, especially at higher resolutions where the finer detail is more susceptible to damage. We've observed that plates with a specialized surface treatment optimized for UV inks – offering better ink adhesion and resistance to abrasion – extend their lifespan considerably, even at high resolution printing demands.

Furthermore, the interplay between plate resolution, press type (Kord vs. GTO 46), and substrate significantly impacts the final print. GTO 46 presses, with their stronger impression pressure, might require a slightly more robust plate compared to the Kord. We've seen instances where high-resolution plates, though ideal for fine detail reproduction, exhibit increased wear on the GTO 46 due to the higher pressure. Therefore, a tailored approach is crucial, potentially selecting a slightly lower resolution plate for the GTO 46 if print longevity is prioritized over extreme fine detail. Regular quality checks throughout the printing process, including monitoring plate wear and ink consistency,

CTP Printing Water Plates

In Computer-to-Plate (CTP) technology, plates are pivotal for producing quality prints. Aluminium CTP Plates serve as the streamlined vessels that facilitate the precision printing process. These plates enhance imaging capabilities, compatibility with UV inks, create high-quality meaningful color reproduction, and reduce waste, establishing their primacy in offset printing.

For the Kord and GTO 46 printers, which are highly regarded for their efficiency and precision, the Resolution UV Ink Accepted CTP Printing Plates become partnerships grounded in technical sophistication.

Technical Specifications

-

Material Composition: Aluminium CTP plates are engineered with a coated surface that is formulated specifically to accept UV inks, enhancing durability and print longevity.

-

Resolution Capabilities: These CTP Plates deliver superior resolution, accommodating an optical density range. This capacity becomes essential for intricate designs where sharp detail is critical.

-

Processing Methods: The plates can be processed both thermally or, particularly relevant, using water-based systems. Their UV acceptability allows easy transfer of artwork directly onto the plate surface, a unique offering that reduces turn-around time significantly.

-

Compatibility: Designed yet again with the Kord and GTO 46 printers in mind, these plates ensure compatibility across both machines without sacrificing quality or print integrity. Optimized interactions between ink and substrate lead to vibrant images and minimal downtime.

Functions and Applications

The Resolution UV Ink Accepted CTP Printing Plates expand creative ceilings within the industry. Their primary functions entail:

-

High-Volume Printing: These plates excel under heavy workloads common in commercial printing environments. Print runs can be executed at remarkable speeds with consistent quality, giving Kord and GTO models a competitive edge.

-

Fine Detail Printing: For graphic-intensive strategies such as packaging, advertising, or stationery design, precision is non-negotiable. This CTP plate supports fine detailing and features rich color saturation, allowing the complexion of artistic nuances.

-

Sustainability: The push within the printing community for more environmentally friendly options finds an unlikely ally in these UV ink supportive plates. They utilize less water, require fewer raw materials (thanks to digital workflow efficiency), translating sustainability into practicality.

-

Versatility: Leverage integration of diverse substrates characterized by regenerative restaurants and engaging print materials. The plates have shown adaptive fittings with a variety of UV inks—all contributing favorably towards premium applications for both its users and their clients (custom solutions, specialty packaging, etc.).

-

Reduction in Manual Processes: The sharp resolution allied with synchronization possible with plates allows for adept streaming and engraving fields with zero manual metrics. Automation accelerates household range portfolios leading to improved dosing fields prevalent under environmentally savvier inspections.

https://www.al-alloy.com/a/resolution-uv-ink-accepted-ctp-printing-plate-for-kord-and-gto-46.html