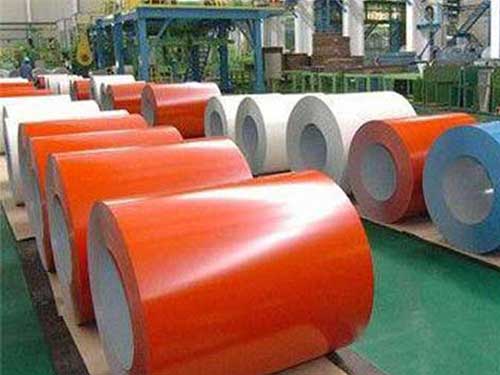

Color Coaed Aluminum Coil AA1100 1050 1060 8011 H14

the Versatility of Color Coated Aluminum Coils: AA1100, 1050, 1060, and 8011 H14

Aluminum has long been celebrated for its lightweight properties and natural resistance to corrosion, which makes it an ideal material in various applications across numerous industries. However, the true beauty of aluminum coils surfaces when they are color-coated. Notably, types AA1100, 1050, 1060, and 8011 H14 is know in the market due to their unique characteristics and extensive applications.

Working with Color Coated Aluminum Coil, specifically AA1100, 1050, 1060, and 8011 in the H14 temper, offers a unique blend of challenges and rewards. The softer alloys like 1100 and 1050 are fantastic for formability, making them ideal for complex shapes and deep draws, especially after coating. However, their inherent softness requires extra care during handling and processing to avoid scratching or marring the delicate color finish. We've had to fine-tune our handling procedures, including specialized tooling and gentler transport methods, to minimize defects and maintain the superior aesthetic quality our clients demand. The slightly harder 1060 and 8011 alloys offer a bit more resistance, beneficial for applications requiring more strength, though they can sometimes be trickier to form without compromising the paint adhesion.

The H14 temper, offering a balance between strength and workability, presents its own set of considerations for the coating process. Achieving a uniform, durable finish across the entire coil is paramount, and we've invested heavily in advanced coating technologies to ensure consistency and longevity. We regularly analyze the adhesion strength of the coating to the substrate, scrutinizing factors like pretreatment chemicals, baking temperatures, and even subtle environmental variations in our production line. Troubleshooting minor inconsistencies, like slight variations in color or gloss, requires a keen eye for detail and a deep

What Sets Color-Coated Aluminum Coils Apart?

-

Durability and Resistance: Because these aluminum coils are coated, they boast an additional layer of protection against climatic conditions, corrosion, and even physical damage. The color-coating process enhances their longevity, making them suitable for exterior applications like roof cladding and siding.

-

Aesthetic Flexibility: The color coating provides limitless possibilities of design. Available in various colors, finishes, and textures, these coils can be tailored to meet specific design criteria, which is especially valuable in the architecture and automotive industries. A manufacturer can seamlessly integrate aesthetic elements into practical objects, providing both form and function.

-

Lightweight Composition: Despite their robustness and durability, color-coated aluminum coils here are lightweight. This property is essential in a world that values efficiency. From reducing fuel consumption in transport to improving structural efficiency in buildings, aluminum creates myriad opportunities to streamline processes.

-

Conductivity and Alloy Strength: Different alloys like AA1100, 1050, 1060, and 8011 H14 exhibit various properties vital for different applications. For instance, AA1100 is known for its high thermal conductivity and excellent workability, making it ideal for products that require forming and welding, while 1060 coatings are sought for their higher resistance in chemical environments.

Applications Across Industries

Architecture and Construction: One of the most prominent applications of color-coated aluminum coils lies in the construction sector. Their exceptional durability, coupled with a stunning finish, elevates buildings while taking harsh climatic conditions in stride. Think facades, cladding, or ornamental architectural features—these coils can be seen adding drama without compromising structural integrity.

Transportation: In the automotive and transportation sector, reducing weight without sacrificing strength is critical. Color-coated aluminum coils are adeptly used in vehicle exteriors, providing benefits in fuel efficiency alongside enhanced aesthetic appeal. Additionally, compliance with regulations around fuel efficiency and emissions makes these materials winners for eco-friendly automotive designs.

Home Appliances: The versatility of color-coated aluminum extends to the manufacturing of household appliances. These coils are commonly used in refrigerators, air conditioners, and washing machines, where aesthetic charm needs to harmonize with performance and energy efficiency.

Consumer Goods: Everyday items, from electronic devices to furniture, utilize color-coated aluminum for its lightweight attributes and vibrant appearances. This has immense implications in custom designs, where consumer preferences for colors and styles can truly personalize products.

https://www.al-alloy.com/a/color-coaed-aluminum-coil-aa1100-1050-1060-8011-h14.html