1050 1060 3003 H14 5052 Color Coated Aluminum Coil

When it comes to crafting durable and visually appealing products, the choice of material plays a pivotal role. In recent years, color coated aluminum coil has gained immense popularity across various industries due to its unique properties and versatility. Among the notable grades of aluminum used in coated coils, 1050, 1060, 3003 H14, and 5052 stand out for their exceptional performance.

1. Overview of Color Coated Aluminum Coil

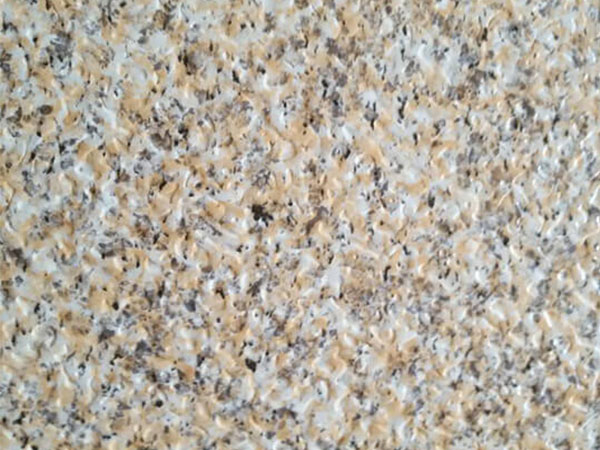

Color coated aluminum coils are aluminum sheets that have undergone a coating process to enhance their appearance and resistance to corrosion. The coating can be tailored in various colors and finishes, making these coils perfect for aesthetic applications. Whether used for roofing, facades, or interior decorations, coated aluminum coils readily capture the essence of modern design.

2. Alloy Grades: 1050, 1060, 3003 H14, and 5052

1050 and 1060 Aluminum Coil

Both 1050 and 1060 aluminum coils belong to the 1000 series, known for their excellent corrosion resistance, high thermal conductivity, and lightweight properties. These grades are predominantly composed of at least 99% aluminum. As a result, they are ideal for applications requiring superior resistance to chemical stress and atmospheric conditions.

- Applications: Both 1050 and 1060 coated aluminum coils are commonly used in electrical applications, heat exchangers, and decorative purposes. Their ability to be easily painted makes them especially attractive for signage and architectural elements.

3003 H14 Aluminum Coil

The 3003 H14 aluminum coil is known for its outstanding workability and medium strength. Containing about 1.2% manganese, this alloy offers enhancements in corrosion resistance and is well-suited for various fabrication processes. The H14 temper signifies that the aluminum has been strain-hardened and partially annealed, providing it with a strong yet workable structure.

- Applications: The versatility of 3003 H14 makes it a go-to choice for products such as cooking utensils, storage tanks, and marine applications. Additionally, its color coating provides an attractive finish for aesthetic projects.

5052 Aluminum Coil

The 5052 aluminum coil belongs to the 5000 series, which means it incorporates magnesium as the primary alloying element. This incorporation results in robust strength, workability, and excellent corrosion resistance, particularly in marine environments. While it is less conductive than 1000 series alloys, 5052 compensates with its remarkable mechanical properties.

- Applications: This alloy is commonly found in the automotive industry for fuel tanks, pressure vessels, and marine components, where durability and weight savings are imperative. The color coated option provides an extra layer of protection and allows for a diverse color palette.

3. Benefits of Color Coating Over Uncoated Alloys

Choosing color coated aluminum coils over uncoated alloys can lead to numerous advantages:

- Enhanced Aesthetics: Color coatings enable manufacturers to tailor the appearance, aiding in appealing designs.

- Increased Durability: Color coated surfaces withstand fading, chipping, and corrosion, ensuring longevity.

- Reduced Maintenance: The smooth surface of coated aluminum is easier to clean and maintain than bare metals.

https://www.al-alloy.com/a/1050-1060-3003-h14-5052-color-coated-aluminum-coil.html