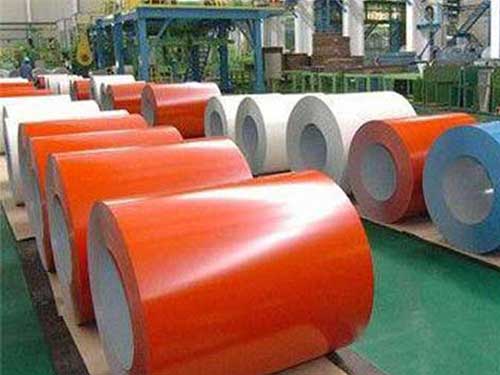

Mill finish AA1100 1050 H18 H14 H24 color coated aluminum coil

In today’s aluminum industry, the mill finish AA1100 and AA1050 color-coated aluminum coils stand out due to their remarkable properties and versatility. Manufactured using high-quality aluminum alloys, these materials cater to a variety of applications across numerous sectors.

Understanding Mill Finish AA1100 and AA1050

Mill finish refers to the initial stage of aluminum processing where the metal is fabricated into thin sheets or coils without any protective coating or enhancements. The AA1100 and AA1050 alloys represent specific grades in the aluminum industry.

AA1100:

This is a form of aluminum with around 99% purity, renowned for its excellent corrosion resistance and high thermal conductivity. Characteristics such as its light weight and ease of workability make it ideal for various industrial applications.

AA1050:

Slightly similar in composition, the AA1050 alloy is characterized by higher levels of aluminum (99.5% purity). It boasts similar benefits, but provides enhanced electrical conductivity, thereby making it particularly useful in electrical applications.

An Overview of H18, H14, and H24 Tempers

The designation of H18, H14, and H24 refers to the temper designation of aluminum, detailing the work hardening and heat treating that the metal undergoes during processing:

- H14: It denotes that the aluminum has been partially hardened, providing increased strength and versatility for varied applications.

- H18: Indicative of a further hardening process, H18 offers high tensile strength, which is key when employing in demanding environments.

- H24: Classified as slightly soft material, H24 provides workability which is essential for applications needing flexibility during installation.

Exceptional Features

The mill finish AA1100 and AA1050 color-coated aluminum coils boast several significant advantages:

-

Lightweight: These coils have a lightweight nature, making them easier to handle and install, helping reduce transportation costs.

-

Corrosion Resistance: Both alloyed materials exhibit exceptional resistance to oxidation and environmental elements, greatly extending their longevity.

-

UV Resistance: The advanced color coating provides a protective layer from UV radiation, keeping the material as beautiful as the day it was installed.

-

Aesthetic Appeal: Available in a range of colors, these coils elevate the aesthetic appeal of construction elements, offering a modern touch to facades and interiors.

-

Thermal Efficiency: Both alloys have excellent thermal conductivity, which makes them ideal for various heat transfer applications, enhancing energy efficiency in buildings.

Diverse Applications

Due to their unique composition and features, mill finish AA1100 and AA1050 color-coated aluminum coils find considerable usage in a plethora of applications:

-

Construction: These coils are frequently used in architectural applications, including roofing, siding, and cladding, where enhanced aesthetics and durability are critical.

-

Transport: Due to the lightweight nature, they offer significant efficiencies in automotive and aviation sectors while providing effective solutions in developments like trailers and bus panels.

-

Electrical Industry: Meanwhile, their excellent electrical conductivity makes them a popular choice in the electrical manufacturing sector for producing transformer housings and electrical connections.

-

Signs & Displays: When it comes to outdoor advertising, the color-coated surface retains vibrancy, making it ideal for sign manufacturing and various display solutions.

-

Furniture: The modern design portability provides endless avenues for creative applications in indoor furniture and cabinetry solutions.

https://www.al-alloy.com/a/mill-finish-aa1100-1050-h18-h14-h24-color-coated-aluminum-coil.html