Aluminum Coil A1050, A1060, A1070, A1100, A1200

Aluminum Coil A1050, A1060, A1070, A1100, A1200: Features and Applications

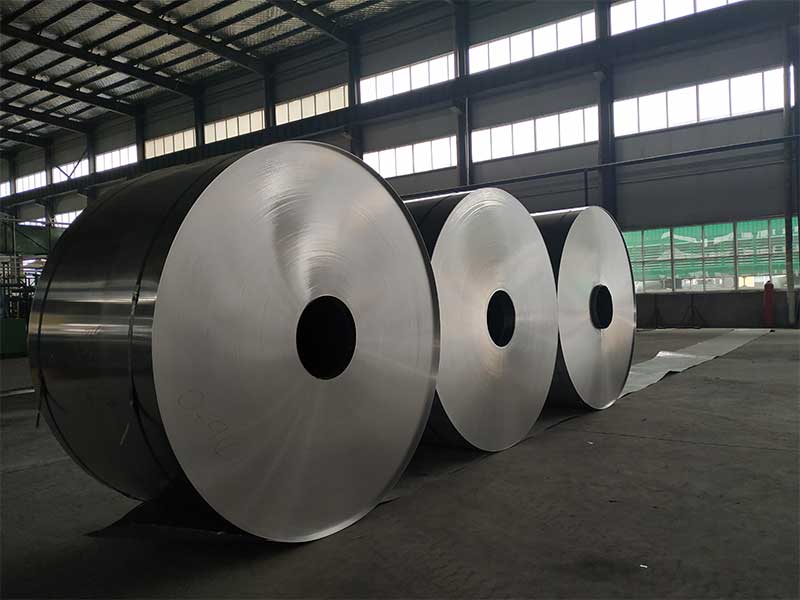

Aluminum coils are an essential component in various industrial applications, offering a combination of lightweight strength, corrosion resistance, and excellent fabricability. Among the myriad of aluminum alloys, A1050, A1060, A1070, A1100, and A1200 have garnered attention for their unique properties and versatile uses.

Features of Aluminum Coil Alloys

- Chemical Composition:

- A1050, A1060, A1070, A1100, and A1200 fall under the 1000 series aluminum alloys, primarily characterized by their high aluminum content (over 99% pure aluminum). This is a benchmark that offers excellent resistance to corrosion and outstanding thermal and electrical conductivity.

- Physical Properties:

- These alloys feature high ductility, enabling them to be easily formed into complex shapes and configurations. Furthermore, their lightweight nature results in enhanced performance and efficiency in applications where reducing weight is critical.

- Thermal Conductivity:

- All five alloys exhibit superior thermal conductivity, making them ideal for heat exchanger applications where efficient heat transfer is necessary.

- Workability:

- Aluminum coils in this series can be commercially cold-worked, facilitating fabrication processes such as bending, shaping, and cutting while maintaining dimensional tolerances.

- Anodization:

- They are particularly receptive to anodizing, a process that enhances their surface appearance and improves corrosion resistance. It allows for a broad color palette in finishing options.

Applications of Aluminum Coils

- Food Packaging:

- The A1100 and A1200 alloys are preferred in the food industry due to their non-toxic nature and excellent barrier properties. Aluminum coils are widely utilized in foil production and packaging, providing protection against moisture, light, and oxygen.

- Electronics:

- With high electrical conductivity, Aluminum A1050 and A1060 are commonly used in electronic components and wiring. The thermal properties of these alloys also make them suitable for the manufacture of heat sinks, helping to dissipate heat from sensitive components.

- Transportation:

- Lightweight aluminum alloys streamline transportation, offering fuel efficiency without compromising strength. Coils designed from A1070 and A1100 alloys are often found in truck trailers, bus bodies, and other automotive applications where reducing overall weight is critical.

- Construction:

- In the construction industry, A1200 coils are effective in roofing and siding applications. Their corrosion resistance ensures durability in adverse weather conditions, enhancing the lifespan of the building materials.

- Pharmaceuticals:

- The Aluminum A1050 and A1100 coils are widely used in packaging for pharmaceutical products, owing to their cleanliness and barrier properties that ensure product integrity.

- Heat Exchangers:

- Aluminum coils with excellent thermal conductivity, such as A1060 and A1070, are particularly valuable in the production of heat exchangers. These applications necessitate high efficiency in transferring heat from one medium to another.

https://www.al-alloy.com/a/aluminum-coil-a1050-a1060-a1070-a1100-a1200.html