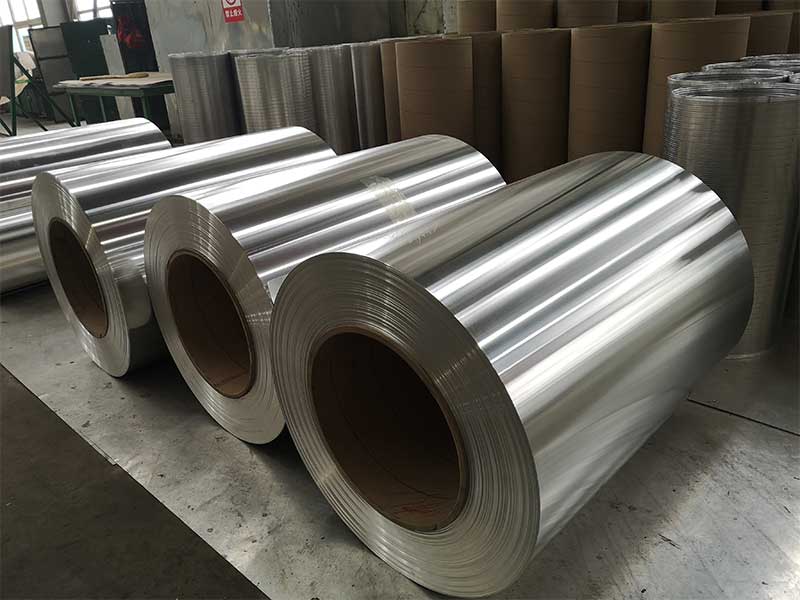

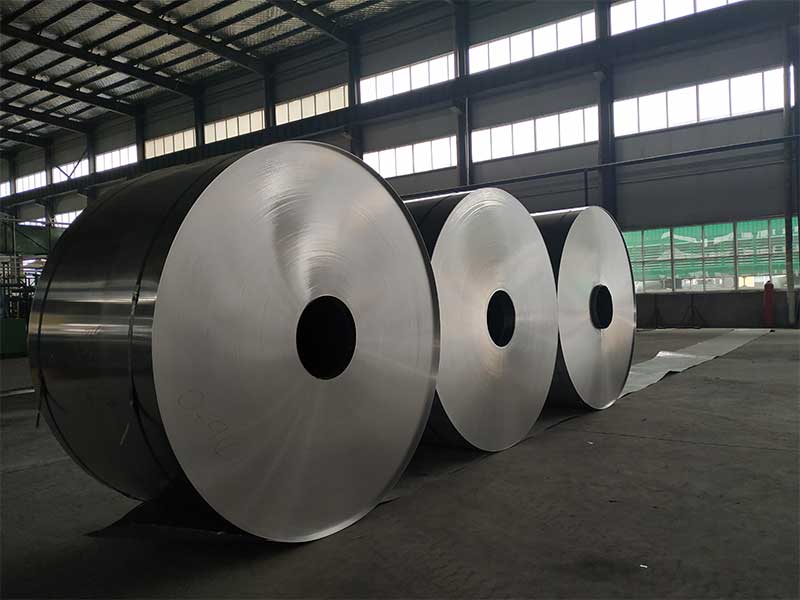

Aluminum coil 3003 5052 1050 1070 H26 H24

The Versatile World of Aluminum Coils: A Deep Dive into 3003, 5052, 1050, and 1070 Grades

Aluminum coils are essential materials in multiple industries due to their lightweight properties, excellent corrosion resistance, and aesthetic appeal. Among the various grades, 3003, 5052, 1050, and 1070, primarily in temper designation H24 and H26, exhibit exceptional characteristics that can cater to a wide range of applications.

Working with 3003, 5052, 1050, and 1070 aluminum coils in H26 and H24 tempers is a daily reality, and I've developed a keen appreciation for the subtle differences between them. The 1050 and 1070, being commercially pure aluminum, are workhorses – easy to form and weld, but their lower strength limits their use in certain applications. Conversely, the 5052, a medium-strength alloy, shines in applications requiring corrosion resistance and good formability, making it a favorite for marine and transportation parts. The 3003, a manganese-containing alloy, offers a balance between strength and formability, often showing up in food-contact applications because of its compatibility. The H26 and H24 tempers represent different stages of hardness; these differences is critical in the manufacturing process because it dictates everything from the appropriate tooling to the potential for springback after forming. Misjudging the temper can lead to costly rework or even scrapped product.

Beyond the specifications, I've learned that the "personality" of each coil can vary subtly depending on the supplier and the manufacturing process. Sometimes, a particular coil of 5052 might exhibit slightly greater springback than usual, necessitating adjustments to the forming dies. Similarly, surface finish can impact the subsequent processes like anodi

Technical Overview of Varieties

1. Aluminum Grade 3003: A Go-To for Durability and Coil Formability

Known for its good workability and corrosion resistance, aluminum grade 3003 contains 1.2% manganese, making it an eligible candidate for stress corrosion happening in areas exposed to salt. This grade is perfect for the fabrication of components where moderate strength and moderate workability are essential, such as chemical equipment, storage tanks, and cooking utensils.

In coil form, the H24 and H26 tempers of 3003 boast improved mechanical properties. H24 indicates that the coil has been strain-hardened and stabilized, while H26 has undergone additional hardening dealing with stress beyond standard practices, allowing for ultimate strength without sag due to extensiveness during forming.

Applications:

- Maeitu louvres and gutters

- Heat exchangers

- Insulation covers

https://www.al-alloy.com/a/aluminum-coil-3003-5052-1050-1070-h26-h24.html