0.125 anodized aluminum plate

the Heart of Innovation: The 0.125 Anodized Aluminum Plate

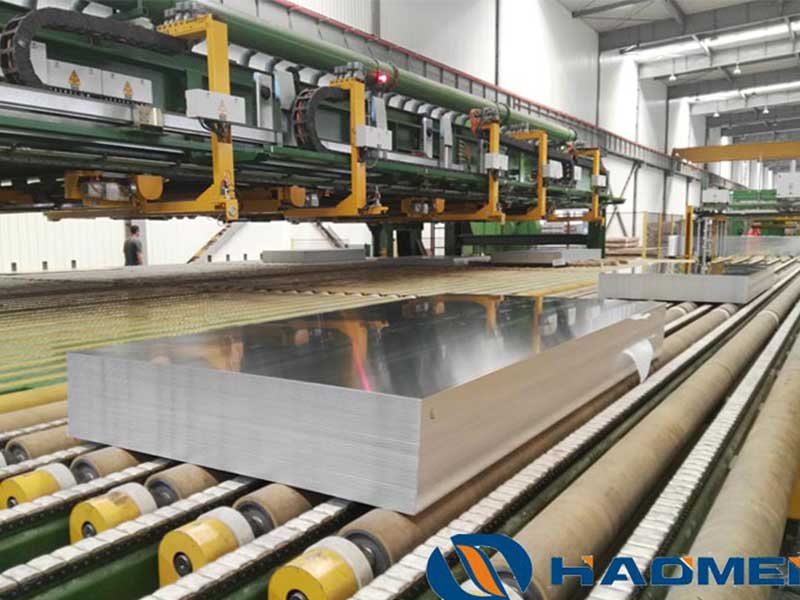

In the realm of metal fabrication, certain products is know for their unparalleled versatility and robustness. The 0.125 anodized aluminum plate is more than just a sheet of metal—it’s a potent solution configured for diverse applications across various industries.

Anodization and its Benefits

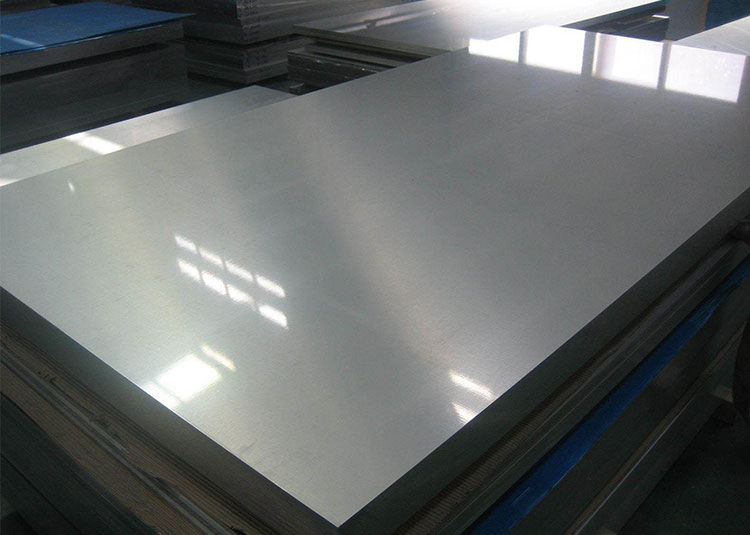

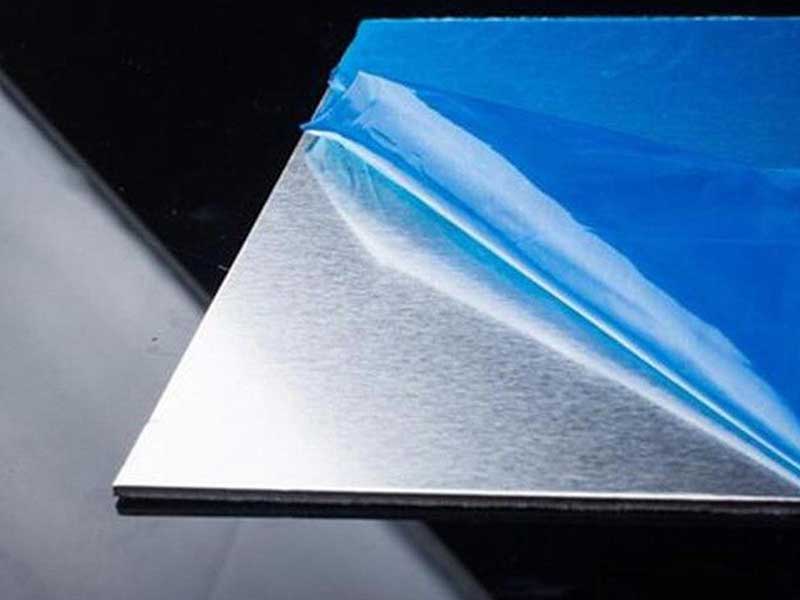

Before diving into the specifics of the 0.125 anodized aluminum plate, it’s crucial to clarify the anodization process. Anodization is an electrochemical process that enhances aluminum's natural oxide layer, resulting in increased resistance to corrosion and wear. This surface treatment not only extends the life of the aluminum but also offers an aesthetically appealing finish that can be dyed in various colors without compromising its structural integrity.

At a thickness of 0.125 inches, or 1/8th of an inch, these plates represent a sweet spot between weight and strength—ideal for applications where rigorous activity and lightweight structure are paramount requirements.

Technical Features That Set It Apart

Several specifications elevate the 0.125 anodized aluminum plate within various markets:

-

Weight-to-Strength Ratio: The 0.125 anodized aluminum plate offers remarkable durability, making it a favored choice for industries where strength is critical without adding unnecessary weight. For example, in aerospace applications, lightweight yet strong materials are vital.

-

Corrosion Resistance: With an anodized surface, these plates resist oxidation—pushing the life of structures built with them significantly longer than uncoated alternatives.

-

Thermal and Electrical Conductivity: Despite anodization, aluminum retains noteworthy thermal and electrical conductivity, fostering its application in heat sinks and electronic housings.

-

Smooth Aesthetic Finish: Beyond practical applications, architects and designers frequently opt for anodized plates for their clean finish—vital in façade applications or pedestrian structures where appearance marries functionality.

Diverse Applications

The potential applications for 0.125 anodized aluminum plates warrant exploration through an industry-centric lens:

-

Aerospace Manufacturing: Where performance and precision are critical, the aerospace industry utilizes these plates for internal components, supporting structures, and casings. The plates serve to both save weight and ensure high strength and thermal performance.

-

Marine Applications: In maritime settings, resistance to saltwater corrosion is essential. Anodized aluminum plates are perfect for boat manufacturing and offshore structures, where contact with water is inevitable.

-

Architectural Elements: In architectural design, aesthetic appeal doesn’t come at the cost of robustness. Anodized aluminum can be found adorning commercial spaces, railings, or elevator partitions. Builders and architects predictably recommend it for its style, fire safety, and resilient capacities.

-

Versatile Signage and Displays: Retail environments often leverage these plates for signage—combining storytelling through beautifully anodized colors while ensuring durability against outdoor elements.

-

Automotive Components: Automobile manufacturers like to incorporate these aluminum plates in vehicle sheathing and body components due to the protection against wear they provide and the visual precision they maintain.

https://www.al-alloy.com/a/0125-anodized-aluminum-plate.html