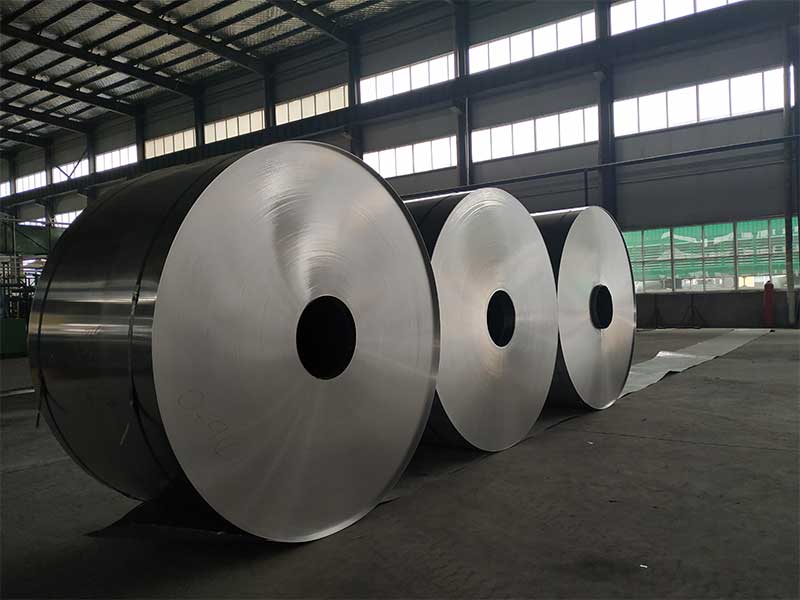

1050 O Aluminum Coil For Deep

Aluminum, noted for its strength-to-weight ratio, is a crucial player in various manufacturing processes. Among its numerous alloys, the 1050 O aluminum coil stands out, particularly in deep drawing applications where form, stretchability, and compatibility with specific processes are vital.

Characteristics of 1050 O Aluminum Coil

Aluminum Alloy 1050 is esteemed for exceptional corrosion resistance, high electrical conductivity, and excellent formability, making it an ideal choice for specific manufacturing processes. The "O" designation indicates the fully annealed condition of the alloy, leading to superior elongation properties, significantly important in deep drawing applications. Here are notable technical specifications of the 1050 O aluminum coil:

-

Chemical Composition:

-

Aluminum: 99.5% minimum

-

Other metals (Cu, Si, Fe, Mg, Mn, etc.): trace amounts ensure maintainability within industry standards

-

Mechanical Properties:

-

Yield Strength: Approximately 50 MPa

-

Tensile Strength: Approximately 104 MPa

-

Elongation at break: 16% (typical), facilitating its extensive beer-ranging shaping capabilities

-

Thickness Range: Available in varying gauges, often ranging from 0.2 mm to 5.0 mm, accorded specific project requirements.

Deep Drawing Process and Importance

Deep drawing is an essential carbohydrate metal forming process whereby a pre-cut blank is drawn deep into a die by contouring forces. The suitability of 1050 O aluminum coil for this process stirs interest due to the following attributes:

-

High Formability: The excellent formability is crucial during deep drawing, as materials must stretch and conform to varied shapes.

-

Weight Advantages: The lightweight characteristic of aluminum enables products to be transported and handled easily, enhancing their usability in industrial applications.

-

Uniform Thickness Properties: The integrity of thickness ensured in production means that the processing quality remains unyielding across complexities.

Applications of 1050 O Aluminum Coil

Thanks to its multifunctional litany, the 1050 O aluminum coil helps usher a plethora of applications such as:

-

Kitchenware and Cookware: Items, excellent for cookware—like pots and pans—which can conduct heat evenly and result in efficient cooking.

-

Automobile Industry: Service parts requiring deep draws, particularly those aimed at minimizing vehicle weight without compromising structural integrity, greatly benefit from this high-performance aluminum coil.

-

Aerospace Components: Components where lightweight materials are non-negotiable, yet safety remains a prime responsibility—resulting in benefits such as fuel efficiency—a vital consideration in aerospace engineering.

-

Casing and Containers: The excellent deep draw process leads to crafting reliable packaging, which is especially necessary for food and pharmaceutical applications.

-

Architectural Applications: Where aesthetic embossing effects and thin, drawn forms provide architectural aesthetics in exterior and interior designs.

https://www.al-alloy.com/a/1050-o-aluminum-coil-for-deep.html