Aluminium Coil Plate Alloy 1060 1100

When we think of aluminum, we often picture shiny foil or cans, but there’s so much more beneath that glimmering surface. Take a moment to appreciate two unsung heroes of the aluminum world: Alloy 1060 and Alloy 1100. These marvelous materials pack a punch with their characteristics, performances, and a surprising range of applications that might have flown under your radar.

What’s In a Number?

Before we dive into their functionality and uses, let's clarify what these numbers signify. In the world of aluminum alloys, 1060 and 1100 fall within the pure aluminum category. They typically contain around 99.6% and 99.0% aluminum respectively, among minimal percentiles of other elements. Although they’re classified as similar, their unique compositions set them apart to serve different needs.

The Essential Functions

High Conductivity

Both alloys boast thermal and electrical conductivity, crucial for manufacturing electrical cables or components needing efficient energy transfer. If you need an effective heat sink or an electrifying circuit design, these alloys should be on your radar.

Excellent Workability

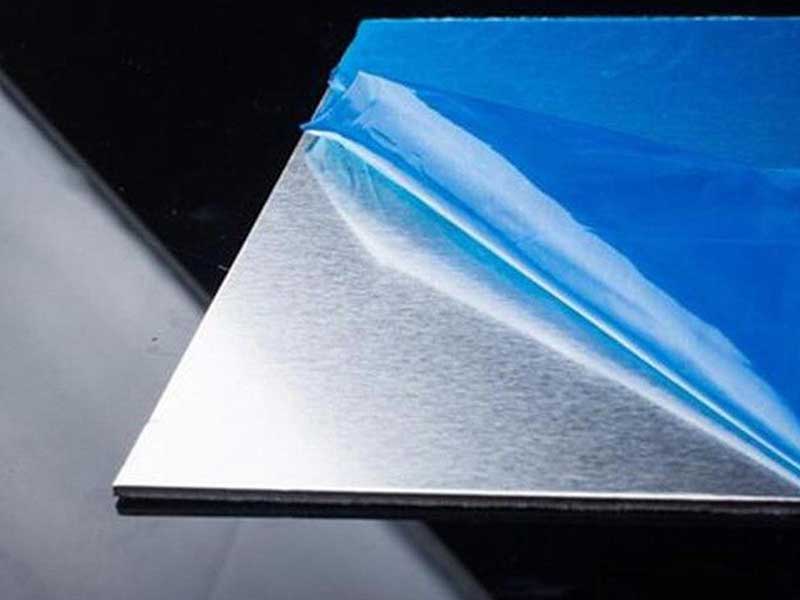

One of the appealing traits of 1060 and 1100 is their malleability. They can be easily shaped and formed through methods like rolling, stamping, or bending. If you're into crafting components like heat exchangers or decorative fabrics with uniquely curved designs, you’ll definitely appreciate this flexibility. It’s like the difference between stretching out a piece of dough versus chiseling away at rock—one is inviting to shape, while the other… not so much!

Corrosion Resistance

Given their inherent properties, both alloys offer substantial resistance to corrosion. This quality is likely to add years to whatever product they help construct prior to needing an upgrade. Whether you are building components for a marine environment or something exposed to harsh atmospheric conditions, this can contribute significantly toward longevity.

Applications That Shine

Architectural Applications:

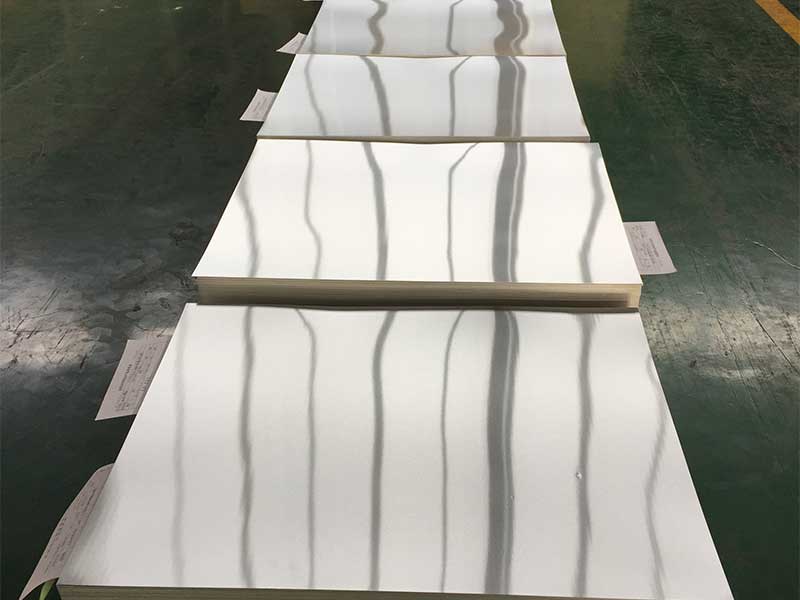

Are you working on a design project that features sleek facades or roofing solutions? Both 1060 and 1100 can be fabricated into lightweight sheets or coils, making them ideal for those spacious commercial buildings. Their high reflectivity can even contribute to energy savings by reflecting sunlight!

Electrical Components:

If you’re knee-deep in electronics, you’ll be glad to know that these alloys contribute to everything from connectors to circuit boards. Their highly conductive nature means you get reliable performance, while being lightweight and cost-effective at the same time.

Food and Industrial Applications:

Getting into production line needs? Both alloys excel in kitchen equipment and sanitary ware. Alloy 1100, particularly, is often chosen in the food service industry due to its non-toxic properties. It’s like that perfect kitchen assistant you didn’t know you needed!

Packaging

Ever seen a soda can? While they are primarily made from other aluminum alloys, coil plates of 1060 find restful inclinations in packaging applications owing to their lightweight, durable features.

A Hidden Potential

The greatness of Alloys 1060 and 1100 isn't just theory—they represent a delicate balance between functionality, aesthetics, and sustainability for manufacturers and designers alike. They might not have the spotlight, but they certainly play a supporting role that allows other, glitzier alloys and materials to shine. By their potential and value, one can greatly enhance both innovation and practicality within diverse projects.

Wrapping It Up

So next time you think about aluminum, zoom in on the fantastic fundamentals of 1060 and 1100. Embrace the details of their light weights but functional robustness for innumerable practical applications. There's a lot more going on under the surface than it seems! If you’re options, think of these unsung allies, delivering quality performances quietly but efficiently across projects everywhere!

https://www.al-alloy.com/a/aluminium-coil-plate-alloy-1060-1100.html