A1050 1100 1060 alloy aluminum sheet

A Comprehensive Guide to A1050, 1100, and 1060 Alloy Aluminum Sheets: Functions and Applications

Aluminum is a material characterized by its lightweight, durability, and exceptional corrosion resistance. Among its various alloys, A1050, 1100, and 1060 is know for their unique properties and extensive applications.

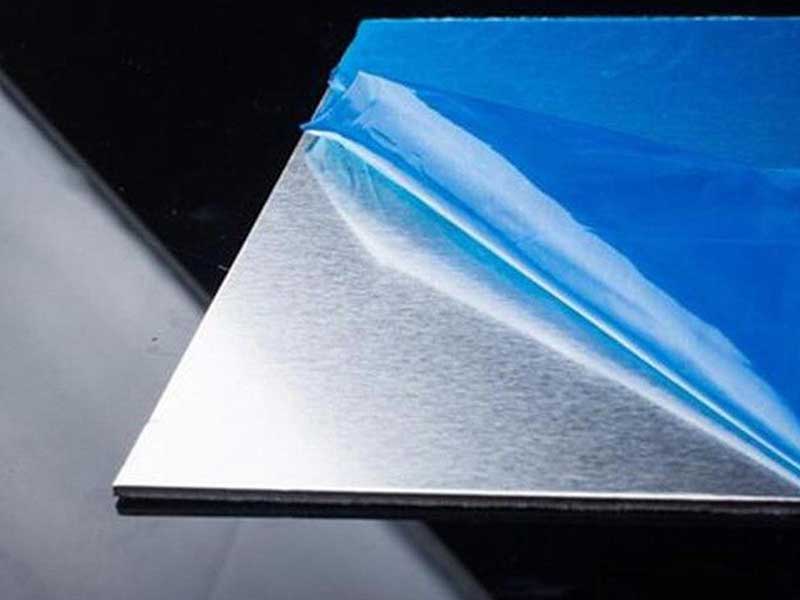

Working with A1050, 1100, and 1060 aluminum sheets daily, I've come to appreciate their distinct characteristics. The 1100, being the purest, is a dream to work with – incredibly soft and easily formable. Its high ductility makes it perfect for deep drawing and spinning operations, although its relatively low strength means we often use it in applications where structural integrity isn't the primary concern. The 1060, with its slightly higher strength thanks to the addition of iron and silicon, offers a good balance of formability and strength, making it a versatile choice for a range of applications, from decorative trim to simple components. We frequently see it used as a base material for further processing, like anodizing. However, the increased strength can sometimes lead to increased springback after forming, requiring adjustments to our tooling and processes.

Interestingly, A1050, despite being very similar in composition to 1100, often behaves differently. Subtle variations in manufacturing or slight impurities can significantly affect its workability. While theoretically similar to 1100, we sometimes find it's more prone to surface imperfections or cracking during bending. This highlights the importance of consistent material sourcing and careful quality control, emphasizing the need for thorough inspection before any major production run commences. Knowing the subtle nuances in how each alloy reacts to various forming techniques, like

the Alloys: A1050, 1100, and 1060

1. Aluminum 1050 (A1050):

- Composition: The A1050 alloy contains 99.5% or higher aluminum, making it one of the purest aluminum types available.

- Characteristics: Notable for its excellent electrical and thermal conductivity, this alloy is also known for its exceptional workability. It doesn’t easily break during road construction tasks and has outstanding corrosion resistance.

- Common Applications: A1050 aluminum sheets are frequently employed in applications requiring high corrosion resistance, making them ideal for chemical and electrical applications. Industries such as packaging, heat exchangers, and solar panels utilize Al1050 sheets extensively.

2. Aluminum 1100 (A1100):

- Composition: This alloy consists of approximately 99% aluminum and traces of other elements, providing a combination of strength and flexibility.

- Characteristics: A1100 is known for its formability and weldability, along with excellent corrosion resistance. The alloy has a sensible tensile strength of around 110 MPa, making it effective in various engineering and construction applications without the need for additional alloying agents.

- Common Applications: With its malleability and appealing aesthetic qualities, 1100 aluminum sheets find their way into cooking utensils, chemical handling systems, architectural applications, and decorative finishes. The food processing industry also favors A1100 due to its non-toxic properties and ease of sanitation.

3. Aluminum 1060 (A1060):

- Composition: Phosphorous, silicon, copper, and iron are routinely less than 0.25% in Aluminum 1060, which speaks to its high purity (99.6% aluminum content).

- Characteristics: This alloy is recognized mainly for its remarkable thermal conductivity spanning up to 220 W/mK, greatest tensile strength reaching around 90–220 MPa, and excellent plasticity. It excels in high-temperature environments as well.

- Common Applications: A1060 aluminum is often used in applications that require good conductivity and corrosion resistance. Examples include heat exchangers, electronics, and lighting appliances.

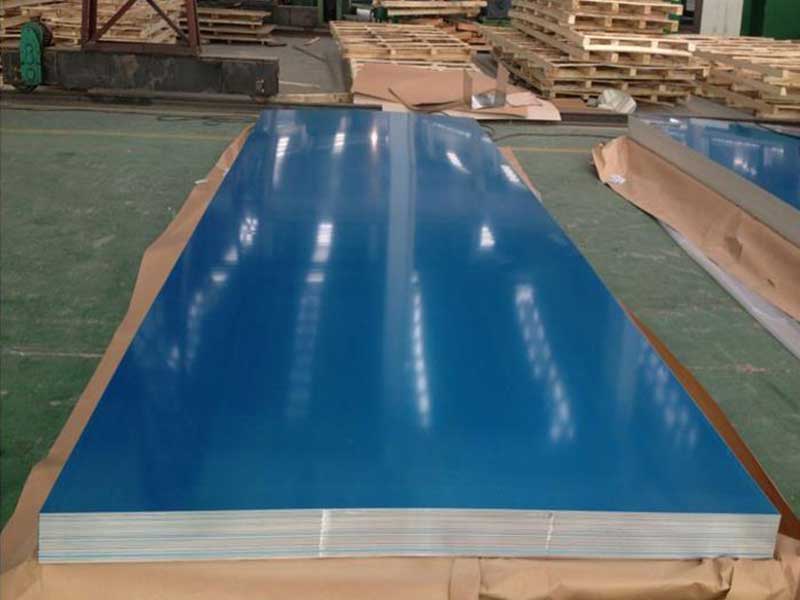

Multifunctional Applications Across Industries

-

Automotive and Aerospace: The lightweight properties of aluminum sheets (using A1050 or A1100) are pivotal in the production of sheet metal components and body parts, contributing to overall vehicle fuel efficiency and performance enhancements.

-

Construction: The use of AAA 1060 aluminum sheets in building facades coats materials that expose them to environmental elements while retaining aesthetic qualities.

-

Electrical Components: High electrical and thermal conductivities of 1050 alloys make these sheets favorable when manufacturing wiring harnesses, integrated circuitry backs, and aluminum fixtures for uniform heat distribution.

-

Food Industry: Aluminum sheets' ease of cleaning paired with their high corrosion resistance reinforces their central role not only in cooking but also in food production units slicing to curating delivery cases.

https://www.al-alloy.com/a/a1050-1100-1060-alloy-aluminum-sheet.html