CTP Plate For Gto 46 CTP CTCP Printing Plate

CTP Plate for GTO 46: Bridging Quality and Efficiency in the Printing Industry

The conventional printing process involving film negatives is becoming a relic in a highly digitized world. In its place, computer-to-plate (CTP) technology has emerged as a beacon of innovation, particularly in offset printing. Among the players in this arena is the CTP plate specifically designed for the GTO 46 model.

What is CTP, and Why GTO 46?

Before diving into the specific details of the CTP plate, let's briefly look at GTO 46. The GTO 46 is a well-regarded offset printing press known for its reliability and ease of use. By integrating CTP technology with this historic format, printers can profit from both traditional strengths and modern efficiency.

CTP enables the direct transfer of digital files onto printing plates without the intermediate process of generating film. The GTO 46 model, often affiliated with short- to medium-run projects, stands as an ideal candidate for CTP plates, offering a bridge between quality and convenience.

Features of CTP Plates for GTO 46

-

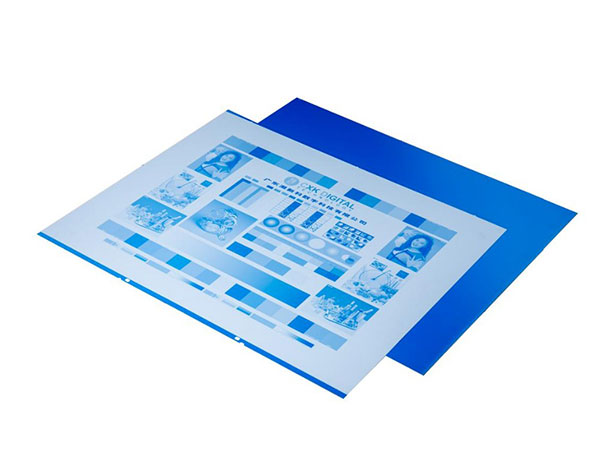

High Resolution and Clarity: One of the standout features of CTP plates is their remarkable precision in image reproduction. The laser imaging employed in the CTP process ensures that text and graphics are not merely clear but exhibit sharpness and detail that often surpass conventional methods. This is particularly crucial for GTO 46 users aiming for exquisite print quality in their outputs.

-

Efficiency Through Automation: With CTP plates, the need for labor-intensive tasks such as film processing and plate development dwindles. This automation translates to faster turnaround times. For businesses that operate on tight schedules, the GTO 46 CTP plates can streamline production, allowing multiple jobs to be completed throughout the day with minimal downtime.

-

Environmental Advantages: Eco-friendliness is another highlight of CTP technology. By omitting the film step and reducing chemistry involved in developing traditional offset plates, the CTP plates for GTO 46 contribute to a lower carbon footprint. This way, printers can embrace sustainable practices without compromising on quality.

-

Cost-Effectiveness: Although the initial technology investment into CTP might seem substantial, the reduction in labor costs, plates, and materials over time leads to greater savings. For businesses focused on quality and sustainability, the switch to CTP can enhance not just efficiency but overall profitability.

-

Versatile Applications: While CTP plates for GTO 46 shine in commercial printing scenarios, their versatility is equally commendable. From producing brochures and flyers to high-quality packaging, the application extends beyond just one domain, further enriching the utility of the GTO 46 as a capable printing press.

Applications in Modern Printing

The applications of CTP plates in combination with GTO 46 presses can be far-reaching:

-

Short-Run Jobs: Businesses often require rapid printing solutions for short-run projects, where CTP technology excels due to its quick setup times.

-

High-Volume Production: Despite CTP being favored in small runs, its efficiency also permits high-volume jobs without sacrificing quality. It’s possible to conduct multiple runs on the GTO 46, maintaining the same high standards across batches.

-

Graphic Intensive Design Work: The capabilities of CTP plates make them indispensable in fields necessitated by graphic precision, enabling varied color applications while maintaining vibrancy and consistency across printed materials.

https://www.al-alloy.com/a/ctp-plate-for-gto-46-ctp-ctcp-printing-plate.html