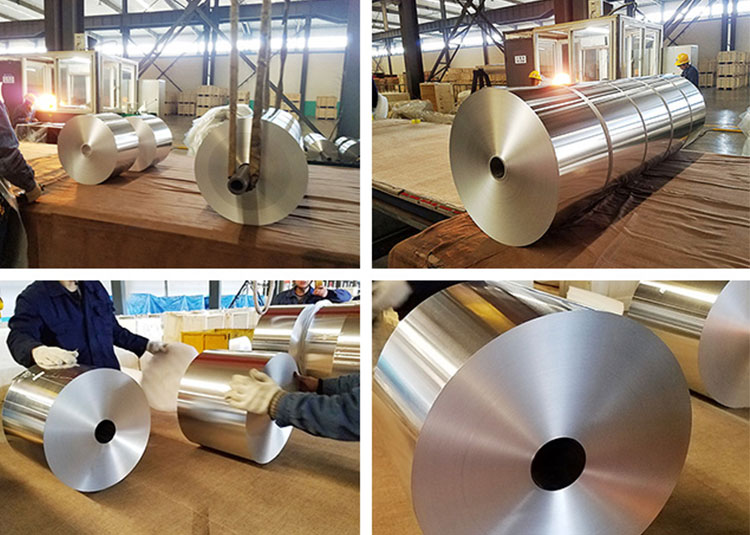

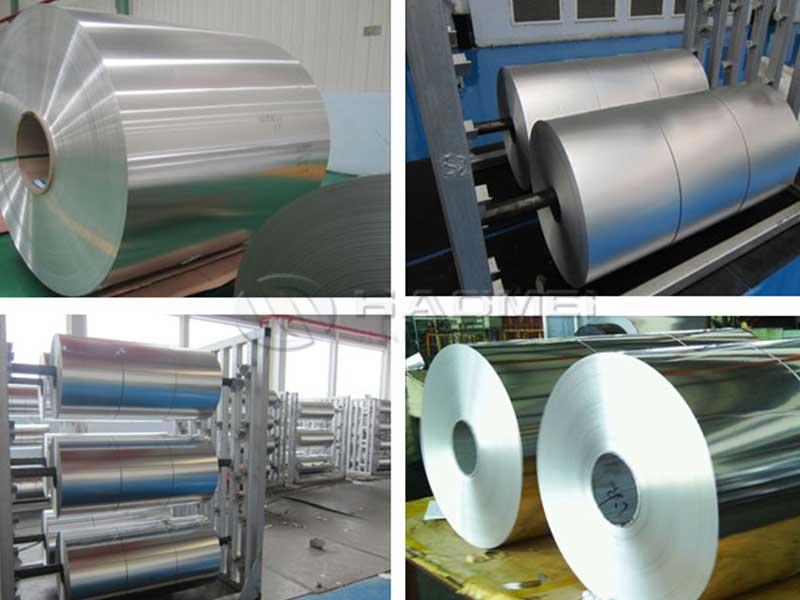

A1235 8011 3003 aluminium foil packaging 6 micron

When it comes to food and industrial packaging, aluminium foil is an unrivaled material known for its versatility, barrier properties, and functionality. Among the various aluminium alloys, A1235, 8011, and 3003 stand out for their exceptional performance in foil packaging applications, particularly at a thickness of 6 microns.

The Importance of Alloy Selection

Selecting the right aluminium alloy is crucial for achieving the best performance in packaging. Here’s a breakdown of each alloy:

1. A1235 Aluminium Foil

A1235 is purely aluminum, often seen as a versatile choice that is lightweight yet functional. It offers excellent thermal conductivity and dead weight reduction, effectively minimizing shipping loads. The high purity of A1235 makes it a top pick for packaging food items, as it is non-toxic and meets safety standards. The thin 6-micron variant remains intact while providing an excellent barrier against moisture, air, and light—all crucial elements in preserving food freshness.

2. 8011 Aluminium Foil

With superior mechanical properties, 8011 aluminium foil is known for its strength and durability. It has good corrosion resistance, making it suitable for a broader range of food and pharmaceutical packaging applications. The 6-micron thickness garners attention for striking a balance between flexibility and sturdiness; while it is thin, it maintains enhanced formability and reliable sealability characteristics. Consequently, the 8011 alloy is commonly used in the packaging industry where durability is essential.

3. 3003 Aluminium Foil

The 3003 alloy is renowned for its high tensile strength and formability, making it an excellent option for demanding packaging applications. In a 6-micron gauge, the lightweight nature of 3003 results in low-cost shipping without compromising the integrity of the contents. This alloy typically finds applications beyond food packaging, such as in construction and automotive industries, providing a high level of flexibility and resistance to punctures.

Why Choose 6 Micron Thickness?

Choosing aluminium foil at 6 microns offers unique benefits that cater to various needs:

-

Lightweight Nature: The 6-micron gauge strikes a balance between lightweight design and operational strength, allowing manufacturers to optimize cost-per-unit during distribution.

-

Enhanced Barrier Properties: The minimal thickness does not compromise barrier qualities. This ensures that light, moisture, and oxygen are effectively blocked, resulting in greater product shelf life.

-

Cost-Efficiency: Thinner foils often provide significant reductions in material cost while also contributing to lower shipping expenditures—a win-win for manufacturers and consumers alike.

-

Exceptional Formability: The 6-micron foil is highly tailorable for diverse applications, allowing for easy manipulation during packaging processes.

Applications and Uses

The A1235, 8011, and 3003 aluminium foil types are widely employed across various sectors. Common applications include:

-

Food Packaging: Ensuring freshness and flavor retention. Ideal for wrapping cold cuts, dairy products, and baked goods.

-

Medical Packaging: Protects medical instruments and pharmaceuticals from bacteria and air exposure.

-

Insulation Materials: Employed in the construction and automotive sectors to retain temperature control.

-

Laminates and Flexible Packaging: Intensely used in the creation of pouches and microwavable packaging.

https://www.al-alloy.com/a/a1235-8011-3003-aluminium-foil-packaging-6-micron.html