Pharmaceutical Packaging Blister Aluminum Foil

In the pharmaceutical industry, protecting the integrity and efficacy of medicinal products is of utmost importance. One of the key components to achieving this is the use of blister aluminum foil in packaging. This specialized type of foil not only ensures that medications remain safe and effective but also demonstrates notable versatility in its applications and features.

Features of Blister Aluminum Foil

1. Barrier Properties

One of the standout features of blister aluminum foil is its excellent barrier properties. It effectively protects the contents from moisture, oxygen, and light—three elements that can significantly impact the stability of pharmaceutical products. This barrier is crucial in preventing degradation, thus preserving the potency and shelf life of medications.

2. Tamper Resistance

Pharmaceutical blister packaging typically employs aluminum foil that acts as a tamper-evident seal. This safety feature not only reassures consumers about the integrity of the products but also mitigates risks associated with contamination or tampering, providing additional trust for end-users.

3. Customizability

Blister aluminum foil can be customized in terms of thickness, coating, and printability. Whether creating easy-open formats or specialized graphics for branding, manufacturers can fine-tune these attributes to cater to specific market needs while ensuring effective protection for the medications inside.

4. Cost-Effectiveness

From a manufacturing cost perspective, blister aluminum foil is an economical packaging solution. While delivering top-notch protective qualities, it remains lightweight and streamlines transportation and storage needs, reducing overall logistical costs for pharmaceutical companies.

5. Compatibility with Various Drugs

Blister aluminum foil is compatible with a broad range of pharmaceuticals, including single-dose and multi-dose medications. This flexibility makes it a preferred choice among pharmaceutical formulators who require packaging material capable of accommodating diverse drug formulations, from tablets to capsules.

Applications of Blister Aluminum Foil

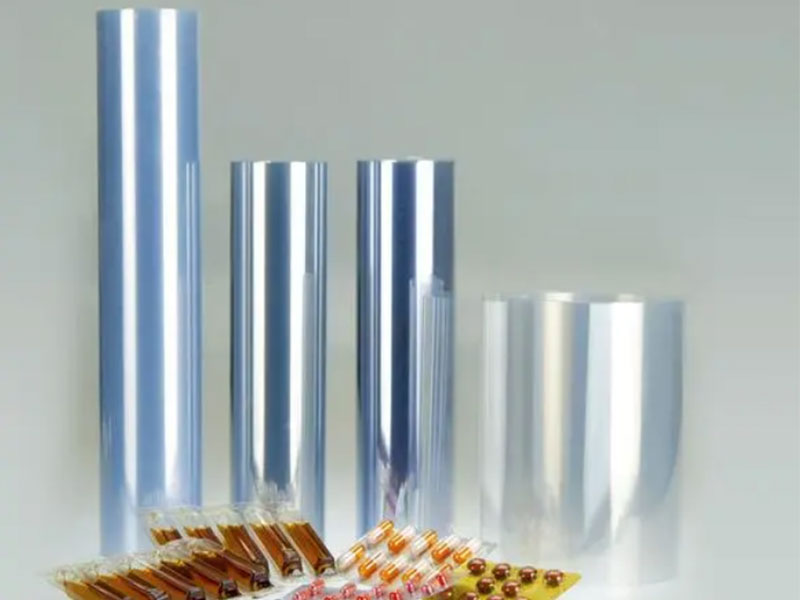

1. Tablets and Capsules Packaging

The most common application of blister aluminum foil is in the packaging of tablets and capsules. The design typically involves forming a cavity where the drug is placed, secured with a lid made of another type of foil or generally heat-sealed. This method not only provides visibility to the consumer but also serves fast access to medication.

2. Pediatric and Geriatric Medication

Blister packaging is particularly beneficial for both pediatric and geriatric markets. Because it allows for precise dosing, it supports improved patient adherence to prescribed regimens. Moreover, the straightforward tear-off design also serves to simplify access for higher-risk populations, mitigating accidental overdose or mishandling.

3. Intravenous Solutions and Injectables

Certain variants of blister aluminum foils can be designed for injectable formulations and intravenous solutions. With the increasing demand in hospital settings for safety and efficiency, these specialty packets limit exposure to external contaminants while ensuring compliance with strict safety regulations.

4. Over-the-Counter Products

In the case of over-the-counter medications, blister aluminum foil packages enhance brand visibility while safeguarding product integrity. Many marketers choose blister packaging to create visually appealing throws on store shelves, directly influencing consumer choice by projecting a message of security and reliability.

5. Biopharmaceuticals

As biopharmaceuticals take the spotlight in the healthcare sector, customizing blister aluminum foil to precise specifications becomes vital. Modern applications can facilitate longer shelf-life requirements, temperature controls, and stability assurances crucial for products like vaccines and other biological therapies.

https://www.al-alloy.com/a/pharmaceutical-packaging-blister-aluminum-foil.html