Alloy 1235 Aluminium Foil Packaging Raw

When it comes to effective packaging materials, few can match the versatility and efficiency of Alloy 1235 aluminium foil. Renowned for its unique properties and wide-ranging applications, this packaging raw material is transforming the way industries think about product preservation and presentation. In this article, we will explore the distinctive features and applications of Alloy 1235 aluminum foil, showcasing why it is an optimal choice for various packaging needs.

Features of Alloy 1235 Aluminium Foil

-

Exceptional Barrier Properties One of the most significant features of Alloy 1235 aluminium foil is its remarkable barrier properties. This foil offers high resistance to moisture, oxygen, light, and other environmental factors, preventing spoilage and extending the shelf life of packaged products. This is particularly beneficial for food products, pharmaceuticals, and other sensitive items that require a protective barrier.

-

Lightweight and Easy to Handle Alloy 1235 aluminium foil is incredibly lightweight, making it easy to handle and transport, while also contributing to lower shipping costs. Its lightweight nature does not compromise durability, as it maintains the strength needed for reliable packaging solutions.

-

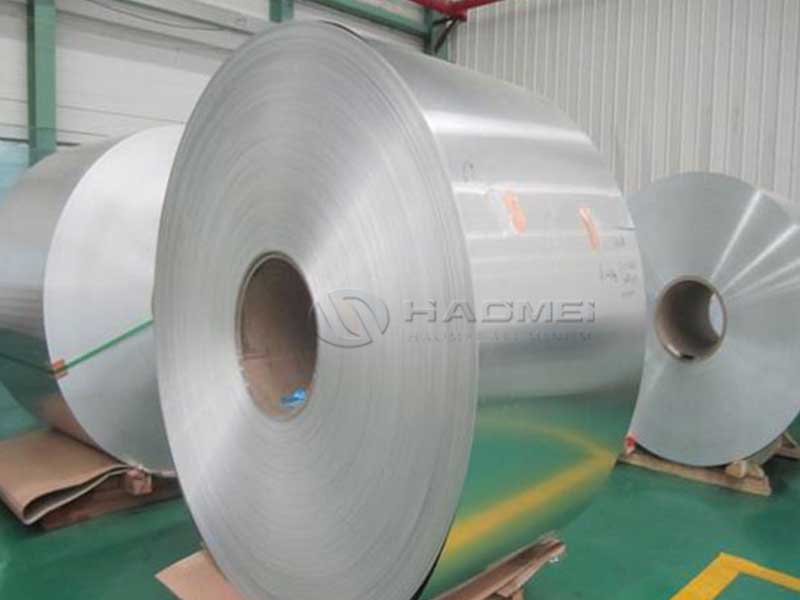

High-Quality Appearance With its shiny and smooth surface, Alloy 1235 aluminium foil enhances the presentation of packaged items. This feature is crucial for brands that wish to aesthetically appeal to customers and elevate their product's market identity.

-

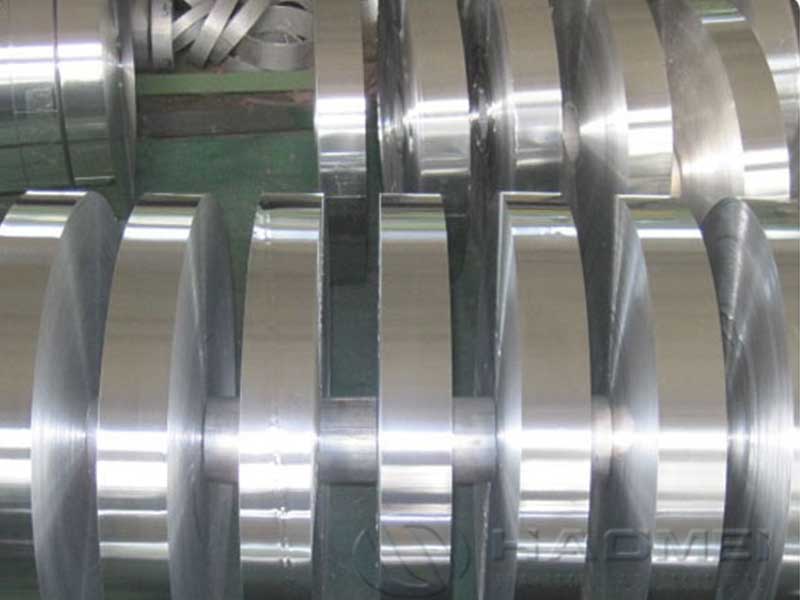

Excellent Ductility and Workability Manufacturers favor Alloy 1235 due to its excellent ductility and workability. The foil can be easily formed into various shapes and sizes without breaking or cracking, allowing for customized applications that cater specifically to the products being packaged.

-

Eco-Friendly Aluminium is a recyclable material, and Alloy 1235 is no exception. Using this type of foil helps promote sustainable packaging solutions, allowing businesses to demonstrate environmental responsibility—a crucial factor for today's eco-conscious consumers.

Applications of Alloy 1235 Aluminium Foil

-

Food Packaging One of the primary applications of Alloy 1235 aluminium foil is in food packaging. Its superior barrier properties effectively protect food against moisture and oxygen, ensuring freshness and preventing contamination. It's commonly used in take-out containers, bakery products, and snack packaging, which is essential in today's fast-paced food industry.

-

Pharmaceutical Packaging The pharmaceutical sector also greatly benefits from Alloy 1235 aluminium foil. The material ensures that medicines are protected from environmental air and light, maintaining their potency over time. From tablet blister packs to ointment tubes, its versatility supports various drug delivery systems.

-

Flexible Packaging Alloy 1235 aluminium foil plays a significant role in the flexible packaging industry. Its malleability allows for creatively designed packaging solutions that are both practical and visually appealing. Pouches, sachets, and wraps made with this foil stand out on shelves while maintaining product integrity.

-

Electrical Conductor Due to its excellent electrical conductivity, Alloy 1235 aluminium foil finds applications beyond packaging. It is often used in electrical components where safe and effective conduction is required, making it integral to electronics manufacturing.

-

Insulation Industry Lastly, Alloy 1235 aluminium foil is employed in thermal insulation systems used in buildings and appliances. Its reflective properties help reduce energy loss, promoting energy efficiency and promoting green building practices.

https://www.al-alloy.com/a/alloy-1235-aluminium-foil-packaging-raw.html