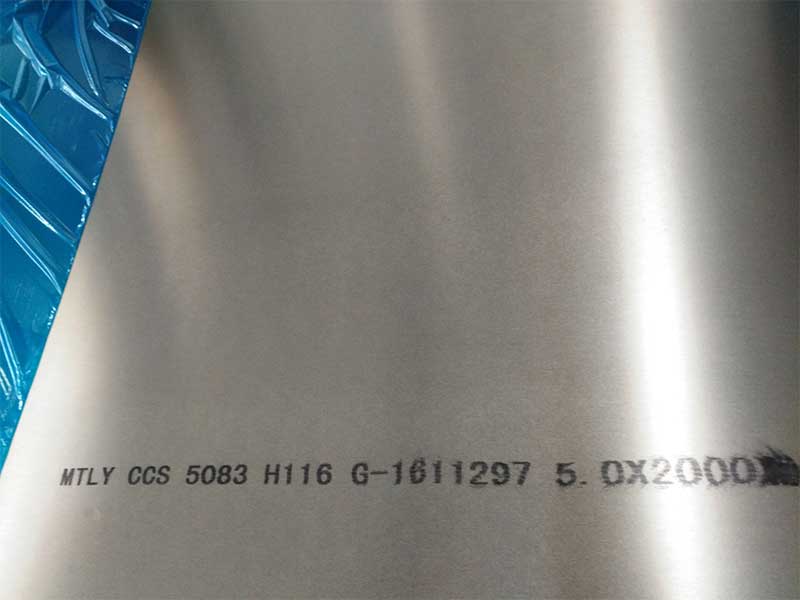

5083 Aluminum Sheet 2mm 3mm 4mm

When most people think of aluminum, they envision lightweight materials great for a range of applications—from packaging to architectural structures. However, among the various grades of aluminum alloys, 5083 stands out due to its unique combination of strength, corrosion resistance, and weldability.

Why Choose 5083 Aluminum?

The 5083 aluminum alloy is part of the 5000 series, famed for its high magnesium content. This definition alone should alert readers to its capability to resist corrosion, particularly in marine environments. Because of its properties, those who work on boats or ships find the 5083 type a preferred choice for hulls or other watercraft structures.

Working with 5083 aluminum sheet in 2mm, 3mm, and 4mm thicknesses is a daily affair, and I've noticed some distinct handling characteristics depending on the gauge. The 2mm sheets are surprisingly flexible for their strength, making them easier to manipulate during fabrication processes like bending or rolling. However, this flexibility also means they're more prone to warping or bowing if not handled carefully during the welding stage. The thicker 3mm and 4mm sheets, while less pliable, offer significant advantages in terms of structural rigidity. They’re ideal for applications demanding higher strength and resistance to deformation. The increased thickness though, necessitates more powerful machinery for cutting and forming, adding to the processing time and energy consumption. We often see the 4mm used in more demanding applications like marine construction, where corrosion resistance is paramount.

From a quality control standpoint, maintaining consistent surface finish across all three thicknesses presents its own set of challenges. The thinner sheets are more susceptible to scratching and marring during handling and transport. We've invested in specialized packaging and handling procedures to mitigate this issue, but it remains a constant concern. Furthermore, the thicker sheets require more precise measurements for shearing and cutting to ensure dimensional accuracy, especially when dealing with larger orders. Despite these challenges, the versatility and inherent properties of 5083 aluminum, coupled with its excellent corrosion resistance, make it a consistently popular material. We

But what makes these 2mm, 3mm, and 4mm sheets of 5083 aluminum distinctly valuable to industries? L

Thickness Matters: 2mm, 3mm, and 4mm Comparison

Each thickness has its contextual applications, which are intrinsically linked to strength, flexibility, and project requirements.

-

2mm Sheets: The lightest thickness available, 2mm sheets are highly versatile for applications requiring minimal weight without compromising durability. In manufacturing processes involving pressure, such as tea trays, automotive panels, or interior architectural designs, these sheets shine brilliantly. Their bending capabilities combined with formability make them perfect for intricate designs.

-

3mm Sheets: Moving up to 3mm offers an optimum balance between robustness and lightweight. This thickness provides a bit more resistance to impact, making it excellent for fabrication projects including ductwork, tanks, and even some structural elements that won’t contribute to excessive weight. Many in the marine industry appreciate this thickness for both functional and aesthetic purposes, creating functional designs that still look sleek.

-

4mm Sheets: At the thicker end of the spectrum, 4mm sheets are engineered for heavier applications, such as structural support bars and frames where a significant amount of stress is expected. These sheets see varied uses in the automotive field, especially for fabricated parts needing rigidity alongside corrosion resistance.

This systematic approach to thickness vibration undoubtedly illustrates that 5083 aluminum is not a ‘one-size-fits-all’ solution but instead offers tailored possibilities to meet specific demands.

Reliability in Challenging Environments

The distinguishing brilliance of 5083 aluminum sheets also lies in their commendable performance under challenging environmental conditions. Those dealing specifically with high-saline regions or extreme temperatures—common in marine constructions, chemical storage, or even certain commercial industries—will appreciate how 5083 maintains its integrity better than standard carbon steels.

Even in the plugging heat of welding and forming applications, 5083's properties help in achieving reliable and clean results, showcasing its weldability.

Corrosion Resistance: A Lifesaver

A principal aspect of aluminum is its innate resistance to corrosion through the formation of a protective oxide layer. However, 5083 takes this ability to new heights. Its enhanced resistance surpasses many common structural materials, making it a lifeline for projects in corrosive environments. Tools and construction workers securing marine components—boat hulls, docks, and immersive environments—benefit remarkably from leveraging 5083's corrosion-resistant features, which translate to extended reliability and reduced maintenance.

https://www.al-alloy.com/a/5083-aluminum-sheet-2mm-3mm-4mm.html