Chemical Composition

The 5083 aluminum plate is part of the 5000 series, known for its high magnesium content, which enhances its strength and corrosion resistance. Its typical composition includes:

- Magnesium (Mg): 4.0-4.9%

- Manganese (Mn): 0.4-1.0%

- Chromium (Cr): 0.05-0.25%

- Silicon (Si): 0.4% max

- Other trace elements, with the balance being aluminum.

Chemical Compositions Marine Aluminum Sheet | |||||||||||

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Other | Al | |

| Each | Total | ||||||||||

| 5A01 | Si+Fe≤0.40 | ≤0.10 | 0.30~0.70 | 6.0~7.0 | 0.10~0.20 | ≤0.20 | ≤0.15 | ≤0.05 | ≤0.15 | Remain | |

| 5454 | ≤0.25 | ≤0.40 | ≤0.10 | 0.50~1.0 | 2.4~3.0 | 0.05~0.20 | ≤ 0.25 | ≤ 0.20 | ≤0.05 | ≤0.15 | Remain |

| 5083 | ≤0.40 | ≤0.40 | ≤0.10 | 0.40~1.0 | 4.0~4.9 | 0.05~0.25 | ≤ 0.25 | ≤ 0.15 | ≤0.05 | ≤0.15 | Remain |

| 5383 | ≤0.25 | ≤0.25 | ≤0.20 | 0.7~1.0 | 4.0~5.2 | ≤ 0.25 | ≤ 0.40 | ≤ 0.15 | ≤0.05 | ≤0.15 | Remain |

| 5059 | ≤0.45 | ≤0.50 | ≤0.25 | 0.6~1.2 | 5.0~6.0 | ≤ 0.25 | 0.40~0.90 | ≤ 0.20 | ≤0.05 | ≤0.15 | Remain |

| 5086 | ≤0.40 | ≤0.50 | ≤0.10 | 0.20~0.70 | 3.5~4.5 | 0.05~0.25 | ≤ 0.25 | ≤ 0.15 | ≤0.05 | ≤0.15 | Remain |

| 5456 | ≤0.25 | ≤0.40 | ≤0.10 | 0.50~1.0 | 4.7~5.5 | 0.05~0.20 | ≤ 0.25 | ≤ 0.20 | ≤0.05 | ≤0.15 | Remain |

| 5754 | ≤0.40 | ≤0.40 | ≤0.10 | ≤ 0.50 | 2.6~3.6 | ≤ 0.30 | ≤ 0.20 | ≤ 0.15 | ≤0.05 | ≤0.15 | Remain |

| 6005A | 0.50~0.90 | ≤0.35 | ≤0.30 | ≤ 0.50 | 0.4~0.7 | ≤ 0.30 | ≤ 0.20 | ≤ 0.10 | ≤0.05 | ≤0.15 | Remain |

| 6061 | 0.40~0.80 | ≤0.70 | 0.15~0.40 | ≤ 0.15 | 0.8~1.2 | 0.04~0.35 | ≤ 0.25 | ≤ 0.15 | ≤0.05 | ≤0.15 | Remain |

| 6082 | 0.7~1.3 | ≤0.50 | ≤0.10 | 0.40~1.0 | 0.6~1.2 | ≤ 0.25 | ≤ 0.20 | ≤ 0.10 | ≤0.05 | ≤0.15 | Remain |

Mechanical Properties

5083 aluminum is renowned for its superior mechanical properties, making it suitable for structurally demanding applications:

Tensile Strength: Approximately 275-350 MPa

Yield Strength: Around 125-280 MPa

Elongation: Typically about 12-17%, providing a good balance of strength and ductility.

Corrosion Resistance

5383 aluminum boasts excellent resistance to corrosion, especially in marine environments. This makes it ideal for applications exposed to saltwater and other harsh conditions. Its corrosion resistance ensures longevity and durability, reducing maintenance needs and prolonging service life.

Applications of Marine 5383 Aluminum Plate

The 5383 alloy's corrosion resistance and high strength make it a favorite in the marine industry. It is widely used in the construction of ship hulls, decks, and superstructures. Whether it's a commercial vessel, a leisure boat, or a marine transport vehicle, the 5383 aluminum plate offers reliability and robustness.

Advantages of Using 5383 Aluminum Plate

High Strength: Provides superior load-bearing capabilities without adding excessive weight.

Corrosion Resistance: Ideal for use in environments where moisture and corrosive elements are prevalent.

Formability and Weldability: Offers ease of forming and welding, which simplifies manufacturing processes and reduces production costs.

Durability: Long-lasting material that withstands wear and tear even under challenging conditions.

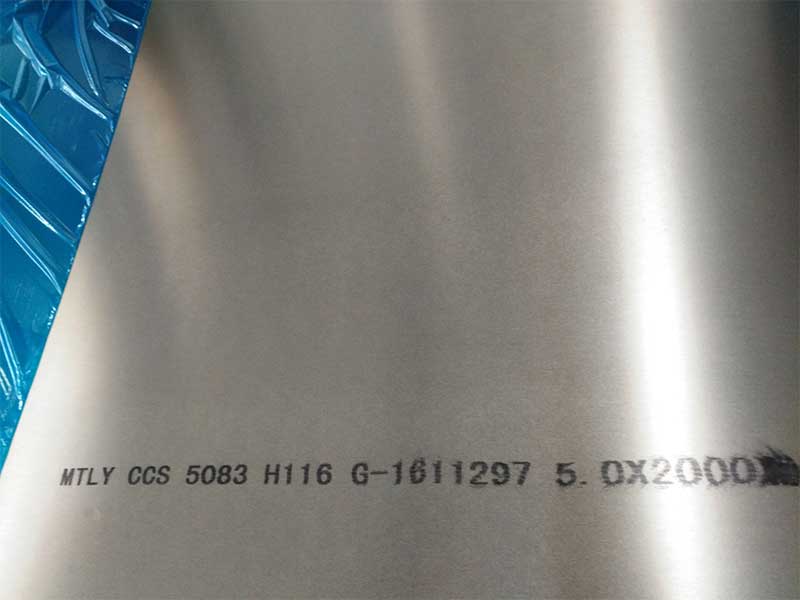

Certificate