Aluminium Sheet For Marine

Aluminium Sheet For Marine

Scope of application

Aluminum alloys with a thickness of 3mm~50mm for the construction of hull structures, superstructures and other offshore facilities.

Sheets and profiles. However, the aluminum alloys specified in this section are generally not applicable to structures whose working temperature is lower than -100℃.

General requirements

Aluminum alloy plates and profiles and their semi-finished products are to be manufactured by a manufacturer approved by CCS.

Aluminum alloys should have good seawater corrosion resistance and weldability.

AlSiMg-based alloys (6000 series) are subject to effective protection measures (such as cathodic protection and/or complete coating protection)

Generally, it is not allowed to be used for components in direct contact with seawater.

Chemical composition of aluminum alloy (%)

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Other |

| 5A01 | Si+Fe ≤ 0.40 | ≤ 0.10 | 0.30-0.70 | 6.0-7.0 | 0.1-0.2 | ≤ 0.20 | ≤ 0.15 | ≤ 0.15 | |

| 5454 | ≤ 0.25 | ≤ 0.40 | ≤ 0.10 | 1.50-1.0 | 2.4-3.0 | 0.05-0.20 | ≤ 0.25 | ≤ 0.20 | ≤ 0.15 |

| 5083 | ≤ 0.40 | ≤ 0.40 | ≤ 0.10 | 0.40-1.0 | 4.0-4.9 | 0.05-0.25 | ≤ 0.25 | ≤ 0.15 | ≤ 0.15 |

| 5383 | ≤ 0.25 | ≤ 0.25 | ≤ 0.20 | 0.7-1.0 | 4.0-5.2 | ≤ 0.25 | ≤ 0.40 | ≤ 0.15 | ≤ 0.15 |

| 5059 | ≤ 0.45 | ≤ 0.50 | ≤ 0.25 | 0.6-1.2 | 5.0-6.0 | ≤ 0.25 | 0.40-0.90 | ≤ 0.20 | ≤ 0.15 |

| 5086 | ≤ 0.40 | ≤ 0.50 | ≤ 0.10 | 0.2-0.70 | 3.5-4.5 | 0.05-0.25 | ≤ 0.25 | ≤ 0.15 | ≤ 0.15 |

| 5456 | ≤ 0.25 | ≤ 0.40 | ≤ 0.10 | 0.50-1.0 | 4.7-5.5 | 0.05-0.2 | ≤ 0.25 | ≤ 0.20 | ≤ 0.15 |

| 5754 | ≤ 0.40 | ≤ 0.40 | ≤ 0.10 | ≤ 0.50 | 2.6-3.6 | ≤ 0.30 | ≤ 0.20 | ≤ 0.15 | ≤ 0.15 |

| 6005A | 0.5-0.90 | ≤ 0.35 | ≤ 0.30 | ≤ 0.50 | 0.4-0.7 | ≤ 0.30 | ≤ 0.20 | ≤ 0.10 | ≤ 0.15 |

| 6061 | 0.4-0.80 | ≤ 0.7 | 0.15-0.40 | ≤ 0.15 | 0.8-1.2 | 0.04-0.35 | ≤ 0.25 | ≤ 0.15 | ≤ 0.15 |

| 6082 | 0.7-1.3 | ≤ 0.50 | ≤ 0.10 | 0.40-1.0 | 0.6-1.2 | ≤ 0.25 | ≤ 0.20 | ≤ 0.10 | ≤ 0.15 |

Aluminum alloys are generally delivered in the following states:

O - annealed state

H111 - Slight work hardening after annealing (such as straightening, etc.)

H112―Condition of hot forming

H116—Aluminum alloy with magnesium content not less than 3.0%, in the state after anti-corrosion treatment

H32 — Stabilized state after work hardening

H321—Aluminum alloys with a magnesium content of not less than 3.0% are work-hardened and then stabilized

T5 - artificial aging treatment after high temperature forming and cooling

T6 - artificial aging treatment after solution heat treatment

Rolled aluminum-magnesium alloys are generally delivered in H111, H112, H116, H32, H321 or O state.

Extruded aluminum-magnesium alloys are generally delivered in H111, H112 or O state.

Extruded Al-Si-Mg alloys are generally delivered in T5 or T6 state.

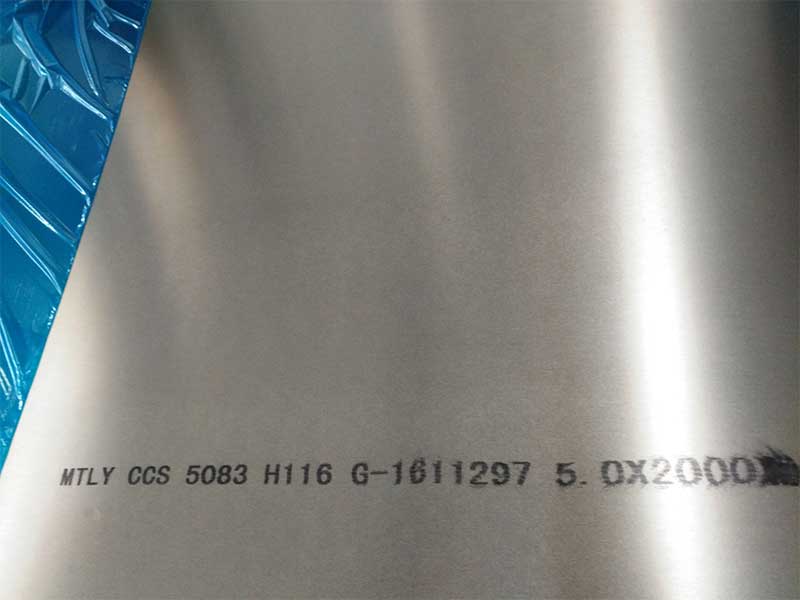

For 5083, delivered in H116 and H321 condition, for seagoing ship hull structure or components often in direct contact with sea water.

Mechanical Properties of Rolled Aluminum Alloys

| Alloy | Temper | Thickness (mm) | Extend Rp0.2(N/mm2) | Tensile Rm(N/mm2) | Minimum elongation at break | |

| 50mm | 5d | |||||

| 5A01 | O | 3 ≤ t ≤ 50 | ≥ 165 | ≥ 325 | 10 | |

| H112 | 3 ≤ t ≤ 50 | ≥ 165 | ≥ 325 | 10 | ||

| H32 | 3 ≤ t ≤ 50 | ≥ 245 | ≥ 365 | 8 | ||

| 5454 | O | 3 ≤ t ≤ 50 | ≥ 85 | 215~285 | 17 | 16 |

| H112 | 6≤ t ≤ 12.5 | ≥ 125 | ≥ 220 | 8 | - | |

| H32 | 3 ≤ t ≤ 6.3 | ≥ 180 | 250~305 | 8 | - | |

| 5083 | O | 3 ≤ t ≤ 50 | ≥ 125 | 275~350 | 16 | 14 |

| H111 | 3 ≤ t ≤ 50 | ≥ 125 | 275~350 | 16 | 14 | |

| H112 | 3 ≤ t ≤ 50 | ≥ 125 | ≥ 275 | 12 | 10 | |

| H116 | 3 ≤ t ≤ 50 | ≥ 215 | ≥ 305 | 10 | 10 | |

| H321 | 3 ≤ t ≤ 50 | 215~295 | 305~385 | 12 | 10 | |

5A01 5454 5083 5383 5059 5086 5456 5754 6005 6061 6062

https://www.al-alloy.com/application/aluminium-sheet-for-marine.html