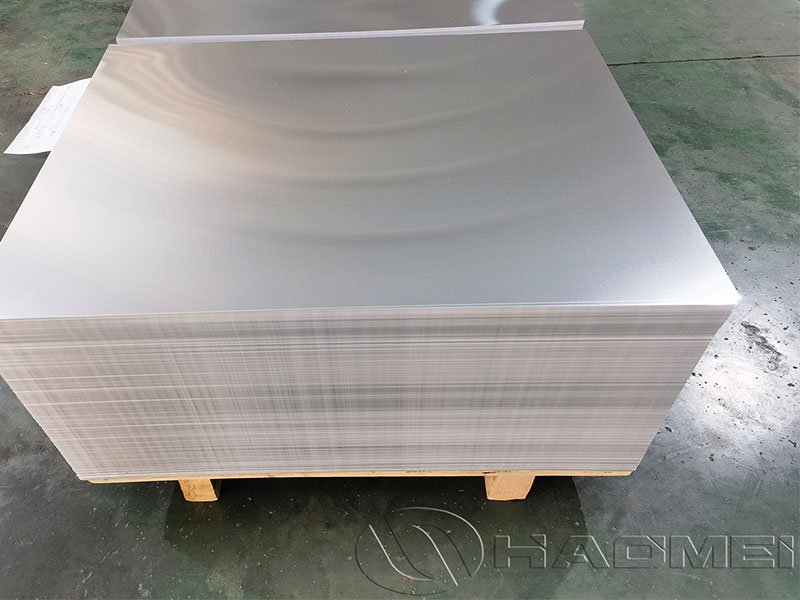

8011 Aluminium closure sheet is used for the bottle cap market. Using a unique rolling technology, Haomei supplies aluminium sheets ideally suited to manufacture the caps for long neck wine bottles, extremely deep drawn and decorated closures, plus a range of pilfer proof caps for beverage bottles, soft drink, juice, isotonic beverage, energy beverage, and other products, such as the 30×60 mm specifications are often used in the wine and spirits segment.8011 aluminum closure sheet.

| Specifications | ||||||||

| Alloy | Temper | Thickness | Width | Length | Coil | Strip | Earing | Diagonal |

| 8011 | H14, H16, H24, H26 | 0.15~0.25 mm (+/-0.005mm) | 500~1000 mm (+0.5mm, -0mm) | 500~1000 mm (+0.5mm, -0mm) | 500~1000 mm | 20~500 mm | 1 | ≤ 1mm |

Chemical Compositions DC & CC Aluminum Closure Sheet | ||||||||||||

| Alloy | Fe | Si | Cu | Mn | Mg | Cr | Zn | Ni | Ti | Other | Al | |

| Each | Total | |||||||||||

| 8011 | 0.60~1.0 | 0.50~0.9 | 0.1 | 0.2 | 0.05 | 0.05 | 0.1 | – | 0.08 | 0.05 | 0.15 | Remain |

| 3105 | 0.7 | 0.6 | 0.3 | 0.3~0.8 | 0.2~0.8 | 0.2 | 0.4 | – | 0.1 | 0.05 | 0.15 | Remain |

| Mechanical Property For Continuous Casting | ||||

| Alloy | Temper | Thickness(mm) | U.T.S(Mpa) | Elongation(%) |

| 8011 | H14 | 0.15~0.25 | 185~205 | ≧2 |

| Mechanical Property For Direct Casting | ||||

| Alloy | Temper | Thickness(mm) | U.T.S(Mpa) | Elongation(%) |

| 8011 | H14 | 0.15~0.25 | 125~155 | ≧2 |

| 3105 | H14 | 0.15~0.25 | 150~200 | ≧1 |

The 8011 aluminum alloy is renowned for its excellent formability and corrosion resistance, making it ideal for producing reliable and efficient closures for bottles, jars, and other containers.

Composition and Properties

8011 aluminum typically contains:

Aluminum (Al): Primary component providing a balance of lightweight properties and strength.

Iron (Fe): Enhances the alloy’s strength and temperature resistance.

Silicon (Si): Improves flexibility and reduces the melting point, aiding in the forming process.

Features of 8011 Aluminum Closure Sheets

Excellent Corrosion Resistance: It is particularly effective at resisting oxidation, which helps maintain the integrity of the packaging in various environments.

Superior Formability: The alloy's composition allows it to be easily molded into complex shapes, making it ideal for various closure designs.

Lightweight and Strong: While being lightweight, 8011 aluminum offers the necessary strength for secure seals, ensuring both cost efficiency and product protection.

Good Surface Finish: The smooth surface of 8011 aluminum makes it suitable for printing and coating, facilitating high-quality branding and decorative options.

Recyclable: As with other aluminum products, 8011 is fully recyclable, aligning with eco-friendly packaging trends and reducing the environmental impact.

Advantages in Packaging

Reliable Sealing: The corrosion resistance and structural properties of 8011 aluminum provide an effective seal, protecting contents from contamination and prolonging shelf life.

Design Versatility: Its formability allows manufacturers to create a variety of closure styles that meet both functional and aesthetic requirements.

Cost Efficiency: Offers a cost-effective solution by combining low material costs with reduced transportation expenses due to its lightweight nature.

Sustainability: Contributing to a circular economy, the recyclability of 8011 aluminum helps companies meet sustainability targets and consumer expectations for green packaging.

Applications Across Industries

The adaptability of 8011 aluminum closure sheets makes them suitable for numerous sectors:

Beverage Industry: Used in caps and seals for wines, spirits, and soft drinks, offering both a secure seal and an elegant presentation.

Pharmaceuticals: Provides dependable closures for medicine bottles, ensuring product safety and integrity.

Cosmetic and Personal Care: Offers attractive and durable closure solutions for creams, lotions, and other beauty products.

Food Packaging: Ideal for sealing jars and containers, helping to maintain the freshness and quality of food products.