Thermal CTP Plate For Printing Equipment

the Functionality and Applications of Thermal CTP Plates for Printing Equipment

In the ever-evolving world of printing technology, thermal Computer-to-Plate (CTP) plates have emerged as integral components that revolutionize the way we produce high-quality printed materials.

Working with thermal CTP (Computer-to-Plate) plates daily, I've noticed a significant performance disparity based on the specific aluminum alloy and the plate's thermal characteristics. We've found that plates with a slightly higher thermal conductivity, while initially seeming less cost-effective, actually yield better print consistency and longevity. This is because the heat from the laser writing process dissipates more evenly, resulting in sharper, cleaner images with fewer defects like edge roughness or inconsistent dot sizes. We've seen a noticeable decrease in plate remakes and print waste since switching to a higher-conductivity alloy, despite a marginal increase in the initial cost per plate. the nuances of thermal transfer and its relationship to the underlying aluminum substrate is crucial for optimizing plate performance.

Beyond the material itself, the processing environment plays a significant role in thermal plate longevity and image quality. Maintaining consistent temperature and humidity levels in the plate processing area is essential. Fluctuations directly impact the plate's sensitivity to laser exposure and its ability to hold the image during the printing process. We've implemented stricter environmental controls, including dedicated climate-controlled rooms for plate processing and storage, which has resulted in a substantial improvement in plate quality and a reduction in production downtime caused by plate-related issues. This emphasizes that the success of thermal CTP plates hinges not only on the plate's inherent properties but also on a meticulously managed workflow.

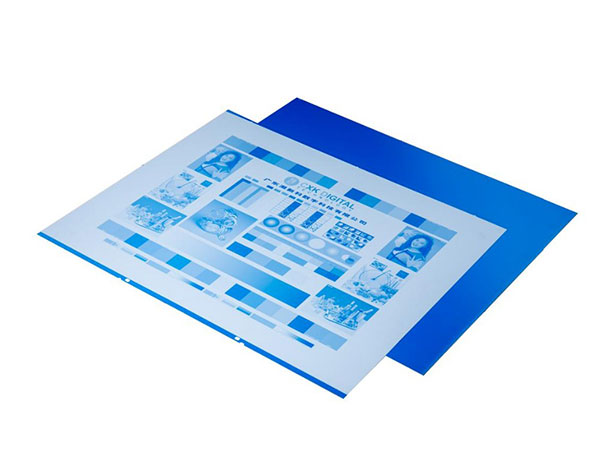

Thermal CTP Plates

A thermal CTP plate is a high-performance aluminum plate that utilizes laser technology to transfer digital images directly onto printing surfaces. Unlike conventional imaging methods that require films and chemicals, thermal CTP imaging employs a computer system to drive laser exposure onto the aluminum plate, ensuring optimal accuracy and efficiency.

Technical Composition: Thermal CTP plates typically feature a base of high-grade aluminum, recognized for its excellent strength-to-weight ratio, durability, and corrosion resistance. The surface of the plate is coated with a unique light-sensitive layer that reacts to thermal exposure. When the laser beam hits the targeted areas, it generates heat, altering the chemical and physical properties of the coating in predetermined patterns corresponding to the digital file. Post-exposure, the plate undergoes a minimal processing routine, involving washing to remove non-image areas, resulting in a plate ready for production.

Functions of Thermal CTP Plates

-

High-Resolution Imaging: Thermal CTP plates are known for producing intricate details with heightened precision. The laser’s ability to articulate with fine resolution allows for superior print quality, ensuring that even the smallest elements of a design are faithfully rendered on paper.

-

Efficiency and Speed: The integration of thermal CTP plates drastically simplifies the printing process. By enabling direct imaging from computer files to the plate, the need for traditional film and additional materials is eliminated. This reduction in steps translates to shorter production times, making prints available more rapidly in a fast-paced market.

-

Reduced Waste: Conventional printing methods unintentionally contribute to significant waste due to off-cuts and residual inks. Thermal CTP plates minimize material wastage through precise exposure and processing, ultimately making the printing process more cost-effective and environmentally friendly.

-

Versatile Applications: These plates are versatile tools that cater to a wide range of printing applications, including commercial printing of brochures, flyers, magazines, and books. They are also leveraged in industries that demand high-quality prints, such as packaging and promotional materials, where clarity and color accuracy cannot be compromised.

Application in Printing Equipment

Thermal CTP plates are compatible with various types of printing equipment, including rotary and flatbed presses. Leading manufacturers like Heidelberg, Sakurai, and Komori design press systems that fully exploit the benefits of this technology, aligning production capability with the advanced functionalities of thermal plates.

-

Enhanced Automation: Integration of thermal CTP plates in printing solutions supports a modern automated workflow, allowing for sophisticated quality control measures and color management practices. The automation also opens the avenue for improvements in scalability without sacrificing quality.

-

Consistency in Quality: With a fully automatic and highly controlled plate-making process, thermal CTP plates deliver consistent results across print runs. This reliability is particularly crucial for industries where color authenticity is paramount; forged prints are vital to brand representation.

-

Sustainability Factor: The growth trajectory of eco-friendliness within the printing sector has made thermal CTP plates even more popular. Their reduced chemical usage and minimal resource consumption align perfectly with current sustainability goals.

https://www.al-alloy.com/a/thermal-ctp-plate-for-printing-equipment.html