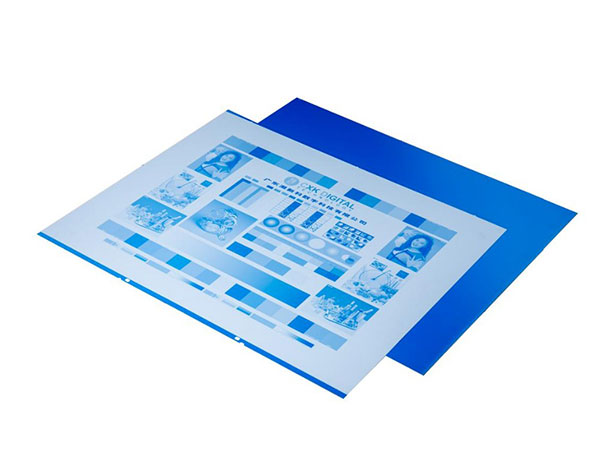

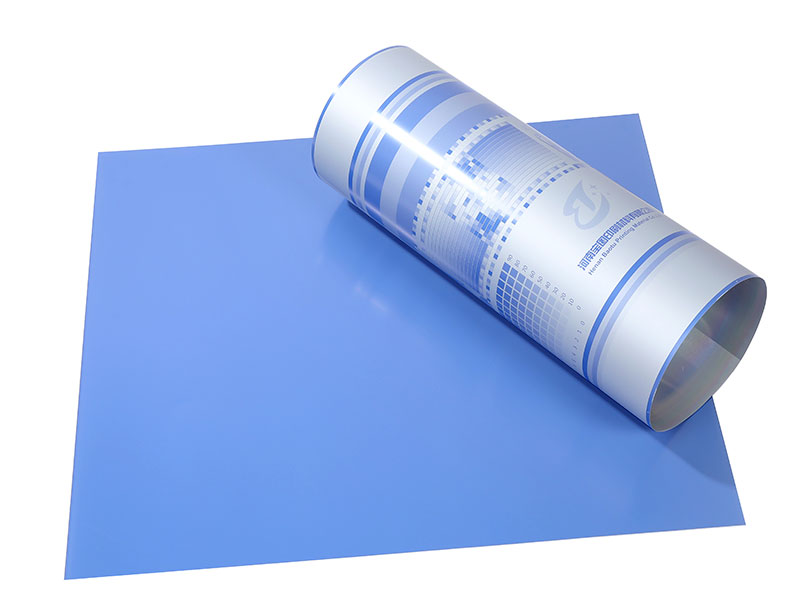

Quality offset thermal CTP offset printing plate

In the rapidly evolving world of printing, where precision and quality are paramount, offset thermal Computer-to-Plate (CTP) printing plates have emerged as a cornerstone technology. Not only do these plates first impress all forms of visual expression on diverse substrates, but they also represent the intersection of quality control and technological advancement.

the Mechanism of Offset CTP

Offset thermal CTP plates simplify the printing workflow by reducing numerous intermediary steps. Essentially, CTP technology enables printers to directly transfer digital files onto a printing plate, eliminating the need for film development. This transformation ensures that the final image clings tenaciously to the plate, enabling fine details to shine and incomparable rendition of colors—qualities that traditional printing techniques could only dream of offering until now.

Working with aluminium CTP (Computer-to-Plate) plates daily, I've gained a deep appreciation for the subtleties that affect the final print quality. It's not just about the plate itself; it's the interplay of the exposure system, the processing chemistry, and the press conditions. A seemingly minor fluctuation in laser power during exposure, for instance, can drastically impact dot gain and ultimately, the fidelity of the printed image. We constantly strive for consistent plate surface quality – ensuring uniformity in the anodized layer and a perfectly smooth surface free from scratches or imperfections is critical for achieving sharp, clean prints with minimal dotting issues. The slightest deviation can lead to plate streaking or unwanted ink build-up, especially on delicate halftone areas.

Beyond the technical aspects, the human element is significant. Proper training of our operators on plate handling, processing, and mounting is paramount. Even a skilled technician can introduce flaws if they aren't meticulous. We've seen improvements in quality directly correlate with better operator training and adherence to standardized procedures. It's a continuous learning process; we constantly analyze our production data, identifying areas for optimization and working to refine our processes for consistently high-quality plates. The ultimate reward is seeing a flawless print – the result of a carefully managed process from the digital file to the final product, a testament to the precision and dedication involved in producing quality aluminium CTP offset printing plates.

For vendors and customers in the printing industry, investing in quality offset thermal CTP printing plates isn’t simply about acquiring tools—it's about integrating meticulous standards into every process. The essence of these plates lies in their consistency; every plate that rolls out is designed to produce precise, repeatable results, setting the benchmark for quality across batches.

The Significance of Quality in Printing Plates

From the perspective of a business owner or print service provider, the factors that underpin the quality of offset thermal CTP plates becomes crucial. Here are some considerations:

-

Materials Matter: Quality CTP plates typically consist of high-grade aluminum with precise chemical treatments. High-durability coatings enhance resistance to wear and grant superior imaging capabilities. It's remarkable to think how a simple choice of alloy or treatment can elevate the overall performance of a printing plate.

-

Thermal Sensitivity: The innovation of thermal sensitivity opened up a new conversation about speed and quality. Unlike conventional alternatives, thermal plates light up with the application of lasers, minimizing the risk of distortion, while also ensuring quicker work turnarounds. This balance creates fewer constraints on print shops struggling with time-bound deliverables.

-

Eco-Friendly Choices: In today’s market, the quality of a product encompasses its eco-friendliness too. High-end plates are increasingly made from environmentally responsible materials and are designed for efficient waste management processes, factoring sustainability into what it means to produce quality prints.

Bridging Tradition with Modernity

While we uphold the virtues of innovation in capillary execution, traditional printing values should not be disregarded. Quality still roots itself in the craftsmanship of old practices. Skilled printers working with high-quality thermal CTP plates can align themselves with experienced technicians to formulate a cohesive partnership, merging traditional techniques of color theory with the rapid deployment of digital efficiency.

Expressing a brand's story depends not only on captivating narratives, but also on their visual representation. Quality plating provides an undeniable format that underscores visual branding, insisting that every print encapsulates an image—clear, replicable, and professionally par excellence.

Future Insights: A Commitment to Innovation

In the future, we are likely to witness even further transformations in the offset thermal CTP plate market. With advancements like artificial intelligence and refined manufacturing technology, quality and customization will redefine how printers conceptualize and execute campaigns.

Embracing integral feedback loops from users will become paramount, ensuring that produced plates adapt intelligently to the printing demands of varied applications, sectors, and artistry expected in bespoke or commercial printing settings.

https://www.al-alloy.com/a/quality-offset-thermal-ctp-offset-printing-plate.html