Prepress offset printing thermal CTP plates

Prepress Offset Printing Thermal CTP Plates: A Deep Dive into Innovation and Productivity

In the ever-evolving world of print technology, the transition from traditional methods to digital solutions has revolutionized prepress processes, especially in the realm of offset printing. Among these innovations, thermal Computer-to-Plate (CTP) technology has distinguished itself as not just a tool for efficiency, but a linchpin in achieving superior output quality.

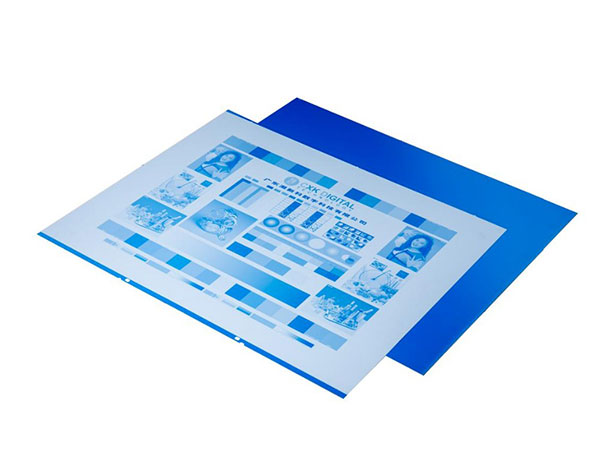

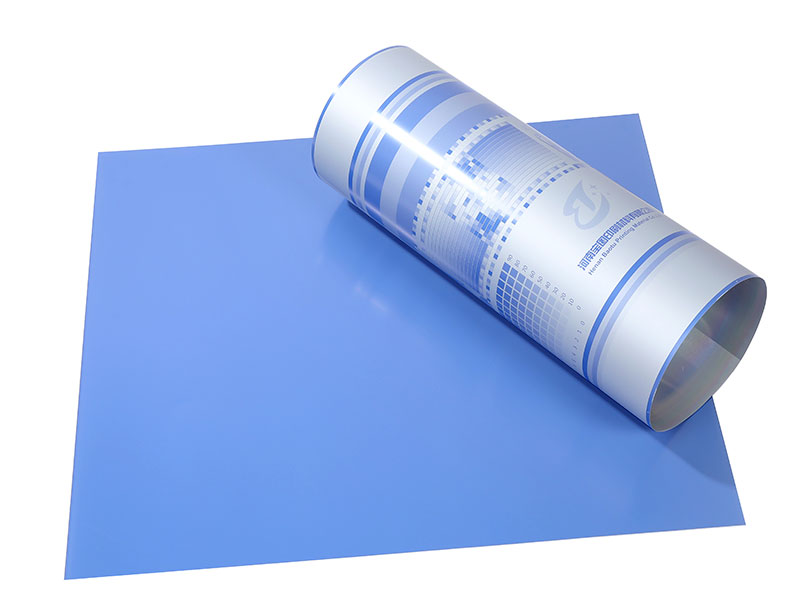

Unveiling Thermal CTP Plates

Thermal CTP is characterized by its innovative imaging technology that produces high-quality offset printing plates directly from digital files. The core feature of thermal CTP plates is their method of exposure, which uses infrared lasers to render images onto the plate surface—often made of aluminum. This laser heat activates a photosensitive emulsion caught on the plate, resulting in precise images that are ready for printing in a streamlined manner.

Features:

-

Precision: The laser’s capability to reproduce high-resolution images with outstanding detail is a significant advantage. You can achieve stark contrasts and sharper tonal transitions, elevating print quality to new heights.

-

Speed: Thermal imaging plates facilitate rapid production turnaround due to their direct output from digital files. This capability leads to shorter prepress cycles, enabling print businesses to respond more swiftly to client needs.

-

No Chemical Processing Needed: One standout feature of thermal CTP plates is the avoidance of traditional developing chemicals. Newer plate designs are often thermal, water wash-free varieties that further streamline workflow and diminish environmental impacts.

-

Cost Efficiency: Over time, reduced labor costs, paired with less material wastage due to precise imagery, translates to significant savings for print operators. The short press setup times and minimal balancing impacts further improve return on investments.

Applications Galore

The landscape of prepress offset printing encompasses a multitude of applications where thermal CTP technology shines. Below we explore some noteworthy realms where thermal CTP provides distinct benefits:

-

Commercial Printing: Industries ranging from marketing publications to packaging production benefit greatly from thermal CTP plates thanks to high fidelity and innate capability for color accuracy and reproduction detail.

-

Short-Run and Digital Printing: Companies involved in rapid release printing, particularly those utilizing short-run jobs or variable data printing (VDP), see thermal CTP positively impact reliability and output quality which augments engagement prospects with end users.

-

Large Format Graphics: With applications bridging changes to signmaking, banners, and promotional artwork, the necessity for flawless imagery and efficiency complements easily with thermal CTP capabilities.

-

Smart Production Workflows: Using thermal CTP setups within smart factories enhances integration within web-based management systems for tracking. This leads to smoother workflows that adapt to complex order requirements and effectively mitigate delays.

-

Sustainability Initiatives: With growing commitments to environmental sustainability, printing operations leveraging thermal CTP plates align more uniformly with eco-friendly printing aspirations through reduced chemical use, facilitating greener markets.

Unique Characteristics

From a distinctive perspective, how thermal CTP plates not only impact production but streamline operations can position a printing business for competitive leverage. Unlike standard lithographic processes, thermal CTP provides modulation characteristics allowing for direct-to-plate capabilities that adapt proactively rather than reactively to changing technological demands.

-

Imaging Lifespan: Significant advancements in imaging longevity allow plates to continue proving highly reusable across numerous print runs, optimizing margin consequently through decreased restaging costs from replacement authenticity.

-

Digital Control Agility: The ability to update, modify, or adjust configurations in virtually real-time without requiring mechanical intervention strengthens operational responsiveness—a major advantage when being confronted by volatile market needs and shortened timelines.

https://www.al-alloy.com/a/prepress-offset-printing-thermal-ctp-plates.html