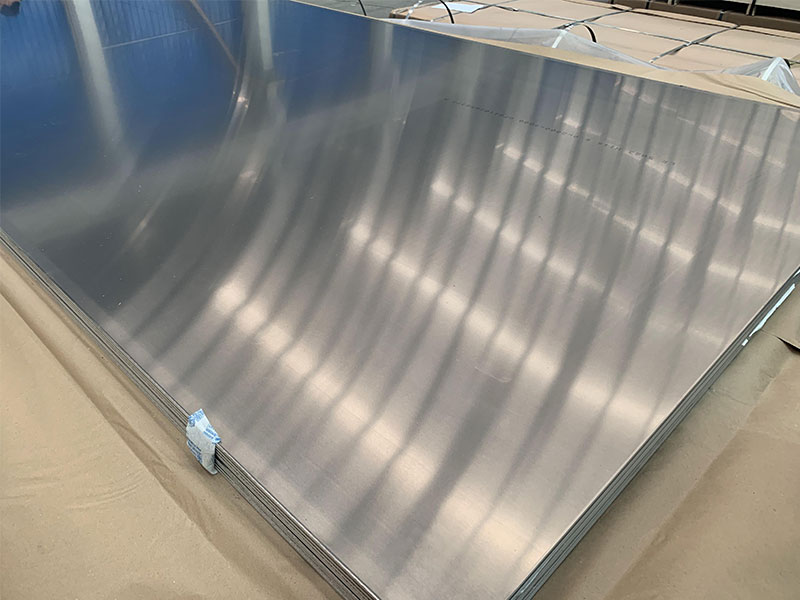

PE and PVDF Coated 5052 Marine Grade Aluminium Alloy Sheet

PE and PVDF Coated 5052 Marine Grade Aluminum Alloy Sheet: A Paradigm Shift in Marine Applications

Aluminum plays a crucial role in the engineering world, particularly in marine applications where durability, strength, and corrosion resistance are essential. Amongst the various aluminum alloys available, the 5052 marine grade aluminum alloy, specifically when coated with Polyethylene (PE) or Polyvinylidene Fluoride (PVDF), has emerged as a forefront material catering to the demands of maritime environments.

Working with PE and PVDF coated 5052 marine-grade aluminum sheet presents unique challenges compared to other coated aluminum products. The 5052 alloy's inherent workability, while beneficial for forming complex shapes, necessitates careful consideration during the coating process. Its higher magnesium content can affect adhesion if not properly pre-treated, leading to potential delamination, especially in harsh marine environments. We've seen instances where inadequate surface preparation resulted in premature coating failure, specifically blistering and peeling under UV exposure and saltwater spray. Therefore, rigorous quality control, including meticulous cleaning and surface activation before coating application, is paramount to ensure the longevity and performance of the final product.

Furthermore, the choice between PE and PVDF coatings significantly impacts the sheet's application. PE coatings offer good corrosion resistance and are relatively cost-effective, making them suitable for less demanding marine applications. However, PVDF coatings, while more expensive, provide superior UV resistance, color retention, and overall durability, making them ideal for exposed marine structures requiring prolonged service life. We've found that the specific end-use application is crucial in recommending the appropriate coating; a yacht hull might justify the expense of PVDF, whereas a less visible interior component might be adequately served by PE. Properly specifying the coating type based on the intended application is a factor in preventing costly replacements and ensuring customer satisfaction.

Coيجة System Utility: Coating Types

PE Coating: The PE coating system provides a balance of cost-effectiveness and aesthetic appeal. It is widely recognized for its array of colors and finishes, which enhance not only the visual aspect of marine constructions but also withstand harsh environmental conditions. With a thickness ranging from 20 to 25 microns, the PE coating acts as a shield against UV rays, hence preserving its appearance over time while resisting fading that typically plague exterior-materials under prolonged sunlight exposure.

PVDF Coating: In contrast, PVDF shines in its unparalleled resistance to drastic climatic conditions and chemical exposure, making it uniquely suited for high-performance applications. Requiring a minimum of 25 microns, PVDF endows the alloy with an exceptional durability that guards against saltwater corrosion, open-flame risks, and even scratches. This open field advantage forms a spectral operating window across diverse marine environments.

Uniqueness of 5052 Marine Grade Aluminium Alloy

Aluminum Alloy 5052 stands tall due to its exceptional strength-to-weight ratio and excellent machinability and weldability. Rated as one of the most trusted alloys for marine fabrication, its inherent properties include:

- Corrosion Resistance: The aluminum naturally develops an oxide layer which, when combined with the PE or PVDF coatings, creates a multi-barrier protection against aquatic environments.

- Formability: Such alloys can undergo significant forming and manipulation during manufacturing, making them an excellent choice for intricate designs found in the marine turf.

- Compliance to Standards: 5052 alloy resounds with various pertinent marine standards which validate its industrial usage in yacht building and cyclist performance, e.g., Lloyd's Register and https://www.al-alloy.com certifications.

Major Applications

-

Boat Manufacturing: The lightweight yet sturdy nature of the PE and PVDF coated 5052 sheets makes them a favored choice in hull construction, enabling sport fishing boats to oust traditional construction materials. They reduce weight, improve speed, and enhance fuel efficiency.

-

Deck Structures: Utilized for creating non-slip deck surfaces, the added layers ensure a long-lasting sheen while minimizing safety hazards, pivotal in commercial vessels subject to fluctuating foot traffic.

-

Marine Equipment Fabrication: Specialty marine equipment, accessories, and other components can likewise be produced due to 5052’s fabrication versatility and resistance to seam tearing and fatigue.

-

Architecture and Detailing: Given their aesthetic potential and durability, these coated sheets serve an enormous swath in coastal architectural projects, conservation vessels, and luxury resorts. Ensuring relevant aesthetic integration–even deploying bright, reflective surfaces that repel solar heat for energy efficiency purposes.

https://www.al-alloy.com/a/pe-and-pvdf-coated-5052-marine-grade-aluminium-alloy-sheet.html