PVDF Color Coated Aluminum Plate Coils

PVDF Color Coated Aluminum Plate Coils: Features and Applications

Introduction

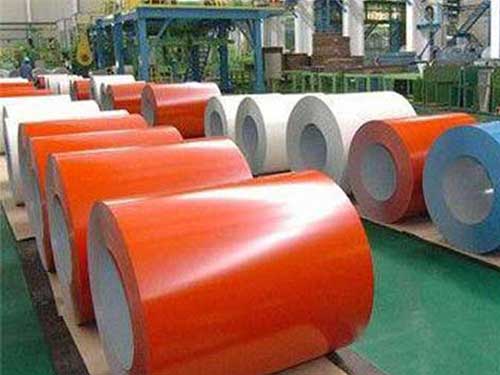

PVDF color coated aluminum plate coils represent a remarkable advancement in the world of construction and manufacturing materials. Known for their durability and aesthetic appeal, these coils are increasingly gaining traction in several industries. In this article, we will explore the features and applications of PVDF color coated aluminum plate coils, enhancing your knowledge of this innovative product.

What is PVDF Color Coated Aluminum Plate Coil?

PVDF, or polyvinylidene fluoride, is a high-performance thermoplastic polymer known for its exceptional chemical resistance and durability. When combined with aluminum plates, it forms PVDF color coated aluminum plate coils that use a unique coating process to enhance both the surface and structural properties of aluminum.

Features of PVDF Color Coated Aluminum Plate Coils

-

Exceptional Durability: One of the most outstanding features of PVDF color coated aluminum plate coils is their ability to withstand harsh weather conditions. Highly resistant to UV radiation, chemical exposure, and extreme temperatures, these coils maintain their aesthetic appeal and structural integrity for years, offering long-term performance.

-

Corrosion Resistance: The PVDF coating acts as a protective barrier, making these coils an ideal choice for environments that are exposed to corrosive substances or direct moisture. This character minimizes maintenance costs and extends the lifespan of the building materials used.

-

Aesthetic Versatility: PVDF color coated aluminum coils come in a myriad of colors and finishes, providing architects and designers with flexibility in creative designs. Whether it’s a bold, bright finish or a subtle, muted shade, the possibilities are virtually limitless.

-

Lightweight and Strong: Aluminum is renowned for being lightweight yet strong, making PVDF color coated coils an excellent option for versatile architecture and construction. They reduce carrying loads for frameworks while maintaining robust structural performance.

-

Sustainability: Aluminum is 100% recyclable. Coupled with the low-energy coating process inherent in PVDF coatings, using these plate coils meets sustainability requirements for modern construction practices.

Applications of PVDF Color Coated Aluminum Plate Coils

The unique features of PVDF color coated aluminum plate coils lend themselves to various applications across multiple sectors. Here are some ways these versatile materials are utilized:

-

Architectural Facades: PVDF coated aluminum is widely employed in building facades. Its ability to resist chromatism and fading due to UV rays enhances modern architecture's capability by delivering visually stunning exteriors that remain vibrant.

-

Interior Cladding: Inside commercial buildings or residential properties, PVDF color coated aluminum plate coils can transform interiors. They offer a sophisticated finish in settings ranging from offices to hotels, making them visually appealing and incorporating functional wall panels.

-

Roofing Systems: Another significant application is in roofing solutions. Commercial and industrial buildings requiring reliable and durable roofing find a reliable partner in PVDF coated aluminum, ideal for high-performance roofs due to their lightweight nature.

-

Signage and Displays: PVDF color coated aluminum plate coils can be utilized in creative signage mediums. Each sign gets an appealing finish, making it eye-catching while providing advanced durability compared to traditional materials.

-

Fixed Architectural Fixtures: Items like canopies, fences, and handrails are also crafted using these coils. Their corrosion-resistance means less wear, resulting in longer-lasting pathways and fixtures in outdoor environments.

https://www.al-alloy.com/a/pvdf-color-coated-aluminum-plate-coils.html