Photographic UV CTP CTcP plate with Developer

In the intricate dance between artistry and technology, the world of print has seen monumental shifts, particularly with the advent of Photographic UV Computer-to-Plate (CTP) and Computer-to-Plate (CTcP) systems. These developments, combined with specialized developers, present an amalgam of precision, efficiency, and sustainable practices, ultimately reshaping how images cut their way from a digital canvas to physical prints.

the Foundation: CTP and CTcP

At the heart of the modern print revolution lies the phenomenon known as CTP and CTcP. These systems eliminate the age-old process of film-based printing, enabling direct transfers of digital images to plates for lithographic printing.

Working with photographic UV CTP (Computer-to-Plate) CtP plates and developer presents a unique set of challenges compared to other CTP technologies. The sensitivity of these plates to UV light necessitates a meticulously controlled darkroom environment to prevent fogging and subsequent print quality issues. Even minor variations in developer concentration, temperature, or processing time can significantly impact the plate's resolution, resulting in inconsistent dot gain and ultimately affecting the final print. We've found that diligent monitoring of developer replenishment and regular cleaning of the processing equipment are critical to maintaining consistent results. Furthermore, the developer's shelf life and the potential for chemical degradation necessitate careful inventory management and regular testing to ensure optimal performance and minimize waste.

Our experience shows that the choice of developer itself is crucial. Different developers offer varying levels of aggressiveness, affecting the speed of processing and the resulting plate profile. An overly aggressive developer can lead to premature plate degradation and reduced lifespan, increasing costs. Conversely, a less aggressive developer might require longer processing times, impacting overall productivity. We've found that optimizing the developer selection based on the specific plate type and press requirements is to maximizing efficiency and print quality. Furthermore, the interplay between developer characteristics and environmental factors like temperature and humidity is essential for consistently achieving optimal results and minimizing plate defects.

-

CTP (Computer-to-Plate): Adopts a dry or thermal imaging process by which images are produced directly onto the plate, generally incorporating a more simplistic media approach.

-

CTcP (Computer-to-Convention Plate): Nearing conventional methods, CTcP stresses compatibility with traditional workflow while still leveraging digital innovations. The nuanced progression optimizes quality at similar costs to historical methods.

Both systems offer scalability for printers, negating time-consuming steps while increasing run volume in quick intervals. With precise registration and consistent results, they become the cornerstone upon which the graphic industries build their unique identities.

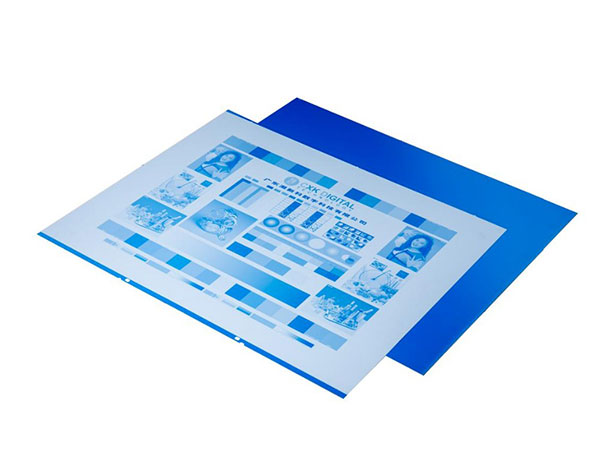

A Closer Look at Photographic UV Plates

Emerging from silver halide technology, photographic UV plates seamlessly merge with modern printing requisites. The annunciation of the term “photographic” might evoke thoughts of fragile emulsion layers or reel-to-reel film, yet today’s photographic UV plates masterfully execute excellence at a molecular level.

Utilizing the capabilities of ultraviolet light to expose the desired image efficiently, these plates enable detailed insights that carbon masks once monopolized. Moreover, the capacity for fine detail reproduction with increased stability opens avenues for brilliant design refraining from historical constraints.

Developers: The Unsung Heroes of the Process

However, the conversation about photographic plates would be incomplete without highlighting the indispensable role of developers. Often overshadowed by the glitzy façade of the high-tech plates themselves, these compounds work tirelessly behind the scenes, ensuring the image’s integrity shines through.

-

Compositional Chemistry: The developers are usually composed of alkaline aqueous solutions that interact chemically with the photographic emulsion, ‘developing’ the latent image through distinct chemical reactions. these reactions not only enhances an operator's skill set but also affords insight into troubleshooting.

-

Fine-Tuning Results: They allow for the optimization of tonality, depths of color, and contrast. Every printer has nuanced variations in their desired palette, making the selection of an appropriate developer paramount not just for quality but also for durability, longevity, and ink adhesion.

-

Sustainability Angle: With the ongoing shift toward environmentally-friendly methods, developers now come in non-toxic formulations, providing a gentler touch on ecosystems while retaining their reliability in producing high-resolution images.

The Reliability Habitus

The seamless symbiosis formed by using photographic plates and quality developers manifests tangible outcomes – exquisite designs bursting to life with enviable distinction. Advanced printers now operate living entities of quality through these supportive surfaces, finding inspiration at unforeseen intersections and evolving their artistic freedom.

Beyond Aesthetics: The Larger Picture

As the printing landscape recalibrates through advancements in technology, the end products serve a greater purpose. Surpassing the average aesthetic aspirations, optimized UV CTP and CTcP plates engage a broader scope: sustainability. The high-volume efficiency breathes new life into environmentally-friendly practices, advocating for responsible production methods that not only cater to consumerism but also minimize adverse ecological impacts.

https://www.al-alloy.com/a/photographic-uv-ctp-ctcp-plate-with-developer.html