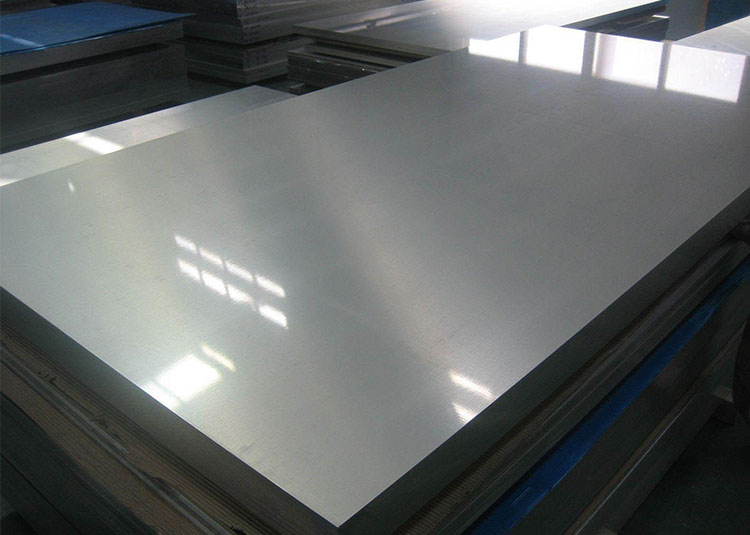

ASTM 7075 T6 Aluminium Sheet

Unveiling the Excellence of ASTM 7075 T6 Aluminium Sheet

In the wide spectrum of materials that shape our modern world, aluminum alloys hold a paramount position, balancing weight, strength, and versatility. Within this domain, the ASTM 7075 T6 aluminum sheet shines like a beacon of engineering marvels. Known for its unparalleled strength and resilience, this alloy has carved out its niche in various demanding industries.

Working with ASTM 7075-T6 aluminum sheet daily reveals its strengths and quirks. Its high tensile strength and fatigue resistance are invaluable for applications demanding robust performance, making it a favorite for aerospace components and high-stress structural parts. However, its high strength comes at a cost; it's significantly more difficult to machine than softer alloys. We frequently encounter issues with tool wear during fabrication, requiring specialized tooling and careful machining parameters to avoid cracking or chipping. Furthermore, its susceptibility to stress corrosion cracking necessitates stringent quality control measures throughout the production process, from raw material inspection to final surface treatment. Careful attention to heat treatment and post-processing is crucial to ensure consistent mechanical properties and prevent premature failure.

Beyond the technical challenges, we've noticed a fascinating interplay between material properties and customer expectations. The demand for 7075-T6 often stems from a desire for lightweight, high-strength components, but the inherent difficulty in processing often translates to higher production costs. This leads to constant negotiations with clients regarding design tolerances and surface finish requirements, balancing the need for optimal performance with the economic realities of manufacturing. We've found that close collaboration with design engineers early in the product development cycle is essential to optimize designs for manufacturability and minimize waste, resulting in both cost savings and superior product quality.

Exceptional Strength-to-Weight Ratio

The hallmark of ASTM 7075 T6 aluminum is its outstanding strength-to-weight ratio. Rated at approximately 570 MPa in yield strength, this alloy stands strong, making it an outstanding performer in comparisons with its steel counterparts, dramatically reducing overall component weight without compromising integrity. The T6 temper indicates a T6 heat treatment process, whereby the alloy is solution heat treated and artificially aged, resulting in a substantial increase in strength and hardness.

Fatigue Resistance

What clarity can often be taken for granted—strength without the propensity for fatigue—underscores the astute engineering of ASTM 7075 T6. Given its remarkable fatigue properties, this aluminum sheet plays a pivotal role in numerous load-bearing and structural components. Whether aerial or terrestrial, parts subjected to cyclical loading can thus rely on the consistency and reliability of this formidable alloy.

Formability and Workability

Despite its mighty stature, one might assume that 7075 T6 is difficult to work with. Interestingly, for a material of its strength, its formability is still notable. While not as easy to form as some other aluminum alloys, it can still be cut, machined, and fabricated with the right tools. Therefore, engineers and designers have the freedom to innovate, pushing boundaries without worrying excessively about the limitations of the material.

Corrosion Resistance and Surface Treatment

At first glance, non-alloyed aluminum may make an impression of vulnerability in corrosive environments; however, 7075 T6 excels with surface treatments or protective coatings. Anodizing or painting can readily shield its surfaces, engendering performance longevity without the typical decay associated with prolonged exposure to tentering conditions. This makes it a fitting choice for applications where moisture or chemicals may introduce risks.

Environmental Considerations

In our era of eco-conscious paradigms, the 7075 T6 aluminum sheet also aligns well with sustainability regulations. Its recyclability offers intrinsic value, with aluminum being one of the most recycled materials globally. Choosing 7075 T6 not only supports high-performance endeavors but inherently champions the movement towards environmentally sustainable practices.

Diverse Applications

-

Aerospace Industry: With aviation at the epitome of demanding applications, 7075 T6 provides the robustness necessary for aircraft wings, fuselage components, and supporting structures. Here, engineers need solutions that promise longevity and reliability, and this aluminum alloy delivers spectacularly.

-

Automotive Sector: As the automotive industry pushes for lighter vehicles without sacrificing safety, 7075 T6 sheets are increasingly being utilized in frames and chassis components, contributing unique advantages that enhance fuel efficiency and performance.

-

Sports Equipment: High-performance sporting equipment—such as bicycles, golf clubs, and many racing gear—benefits greatly from the superior mechanical strength of 7075 T6, granting athletes a competitive edge through lightweight components that do not compromise durability.

-

Military Applications: Given its formidable characteristics, 7075 T6 is critical in the construction of military vehicles and protective gear that must withstand harsh terrains and demanding tasks — from aircraft carriers to helicopters.

-

Marine Applications: While typical thought processes may assert that marine environments are damaging, implementing protective coatings on 7075 T6 effectively brings this complex alloy to sea-worthy specifications for components such as hulls and fittings.

https://www.al-alloy.com/a/astm-7075-t6-aluminium-sheet.html