Metal Mirror Anodized Aluminum Plate

In the realm of modern materials, few can match the brilliance and versatility of metal mirror anodized aluminum plates. This innovative engineering marvel not only enhances the visual aesthetics of a myriad of products but also offers unmatched durability and processing possibilities. Delving into its features and diverse applications reveals just how integral this material has become in various industries.

The Shimmering Features of Metal Mirror Anodized Aluminum Plate

Reflection with Purpose

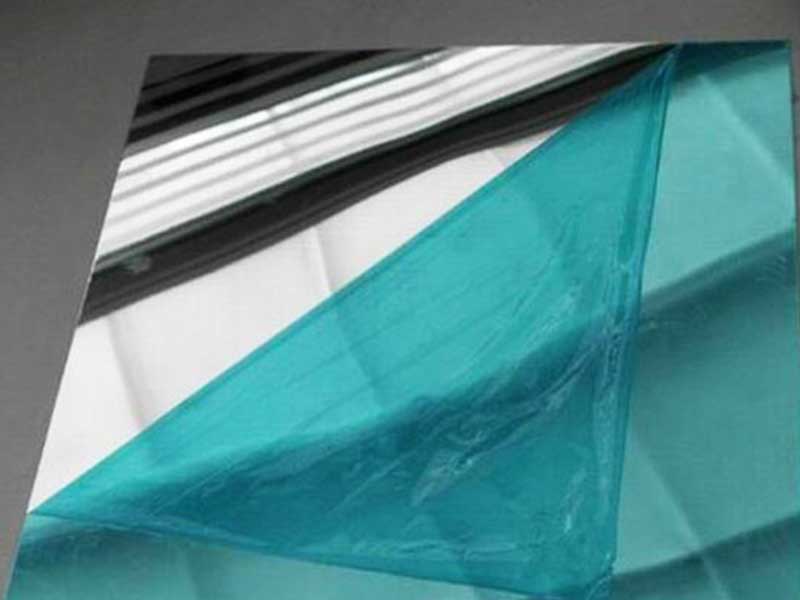

Working with mirror anodized aluminum plate is a fascinating blend of artistry and precision engineering. We're not just making a functional metal sheet; we're crafting a reflective surface of exceptional quality. The anodization process itself is delicate, requiring meticulous control of temperature, current, and chemical composition. A tiny variation can drastically alter the final reflectivity and durability, leading to everything from subtle color shifts to catastrophic surface defects. I’ve personally seen the impact of even minor fluctuations in the power supply on the final product, resulting in batches that were subtly less brilliant than others. It's this constant attention to detail, this pursuit of flawless reflectivity, that sets our product apart. The sheer satisfaction of seeing a perfectly polished, brilliantly reflective sheet emerge from the line is something unique to this particular manufacturing process.

Beyond the technical aspects, there's a real sense of pride in contributing to a product with such diverse applications. From the high-end architectural finishes I've seen in city skyscrapers to the precision instruments used in medical technology, knowing our plates play a role in such visually striking and technologically advanced products is deeply fulfilling. I've even had the pleasure of handling samples destined for use in high-powered telescope mirrors – that's a real highlight of my career here. The challenge lies in consistently maintaining the high standards required for such varied and demanding applications, constantly refining our processes to ensure the ultimate quality and consistency of our mirror aluminum sheets.

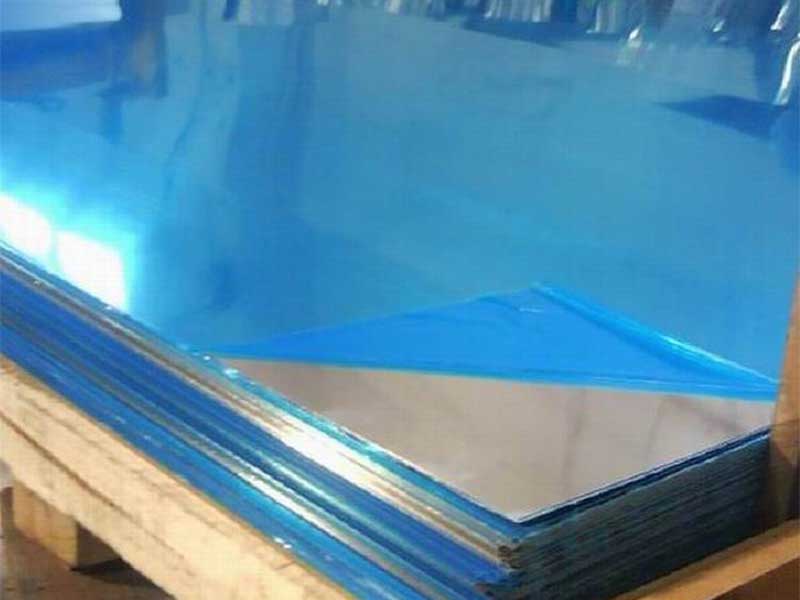

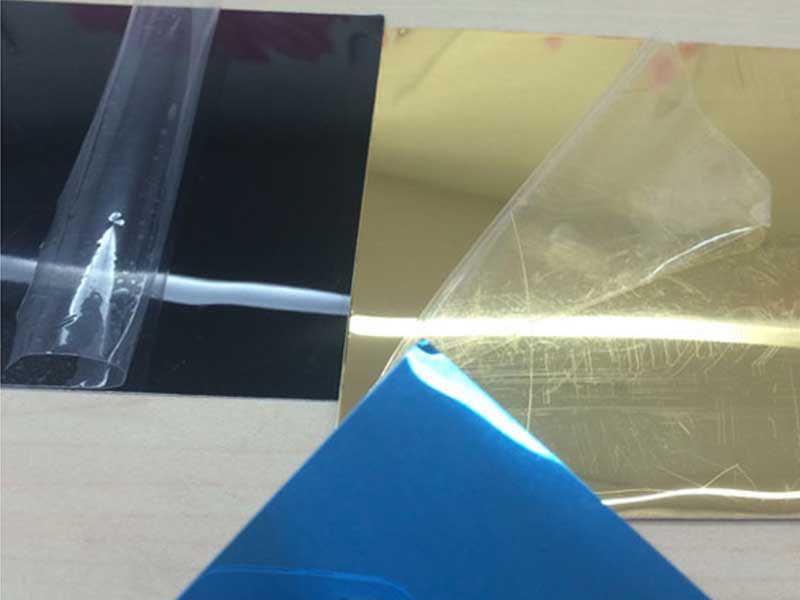

At first glance, the striking reflective surface of a metal mirror anodized aluminum plate is what potently captures attention. This reflective quality is achieved through a high polishing process followed by anodization—a conversion of the aluminum surface into a durable, corrosion-resistant layer. This does not just serve aesthetic purposes; it reflects light with precision, enhancing visibility in poorly lit environments while minimizing energy wastage from artificial lighting.

Corrosion Resistance Meets Lightweight Flexibility

Moreover, anodization imparts an inherent protective layer that guards the aluminum from environmental factors and wear. Unlike standard aluminum surfaces that are susceptible to scratches and oxidation, anodized aluminum holds its ground against rust, adverse weather, and even various chemicals. Engineers and architects often benefit from this durability without compromising the low weight characteristic that aluminum offers, thus ensuring easy transport and handling in implementation.

High-tech Meets Eco-Friendly

Another fascinating perspective lies in the eco-friendly nature of metal mirror anodized aluminum plates. Anodization not only enhances the properties of aluminum but is also a sustainable option thanks to its recyclable nature. Once dismantled at the end of its life cycle, the material can be repurposed without losing quality, reinforcing sustainability initiatives rampant in today's manufacturing landscape.

Broad Spectrum of Applications

Architectural Elegance

The stunning visual characteristics of metal mirror anodized aluminum plates find significant representation in the architectural design sector. From stunning facades of commercial buildings that gleam in sunlight to interior decor elements that evoke modern sophistication, this aluminum type becomes a central designing element. It also acts as a practical solution in inaccessible areas thanks to its resilience against corrosion—indispensable in coastal constructions.

Automotive and Transport Solutions

What’s remarkable is its expanding footprint along the automobile and transport landscape. Manufacturers today leverage this aluminum type in car interiors, enhancing their aesthetic and tactile appeal. Not only does it reduce vehicle weight—contributing toward improved fuel efficiency—but it also holds a prominent place in bus shelters and train cars, environments that boast high foot traffic and require low-maintenance surfaces.

Consumer Products: Where Form Meets Function

Moreover, the consumer goods industry can inefficiently utilize this material. Think of kitchen appliances, small electronics, and even mirrors themselves—metal mirror anodized aluminum imparts stylish elegance while maintaining functionality. Manufacturers benefit from less susceptibility to wear, enhancing product longevity, which in turn builds stronger brand loyalty and customer satisfaction.

Combining Style with Technology

Indeed, architects, designers, and engineers are constantly at the helm of innovation by incorporating technology into their designs. Metal mirror anodized aluminum plates are increasingly important in this venture due to their ability to interface with smart technologies seamlessly. Accessibility systems, signage that requires high visibility, and temperature-sensitive solutions all find compatibility with this versatile material, making daily life smoother and more efficient.

https://www.al-alloy.com/a/metal-mirror-anodized-aluminum-plate.html