1100 1050 1060 3003 mirror aluminum sheets

Have you ever glanced at a sleek mirror finish and thought about the science behind it? You might already be acquainted with aluminum mirror sheets without even realizing it—those reflective surfaces that catch the eye and offer incredible utility in everyday applications. Today, we're looking specifically at mirror aluminum sheets made from alloys like 1100, 1050, 1060, and 3003. Let's uncover the distinct functions and applications these alloys hold, all while keeping it light-hearted and informative.

The Bright Side of Aluminum Alloys

First things first—what separates these alloys? At a glance, the lies in their composition.

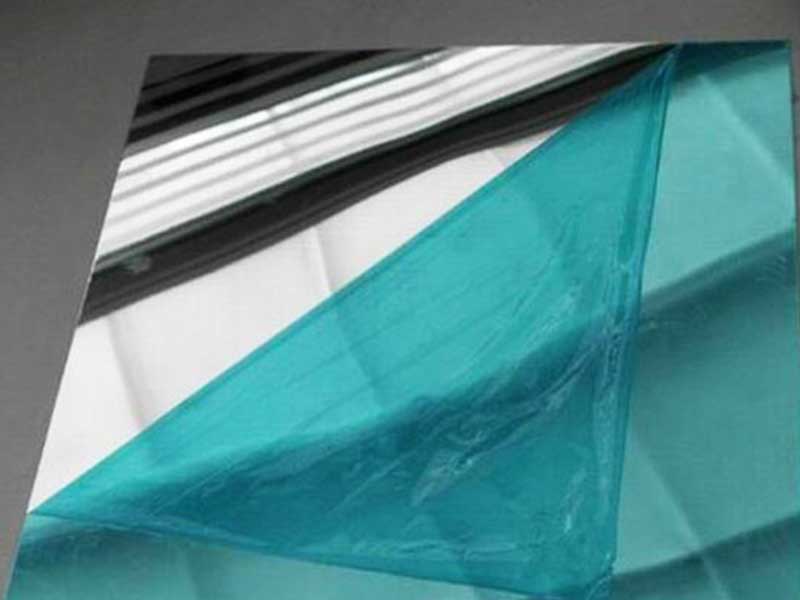

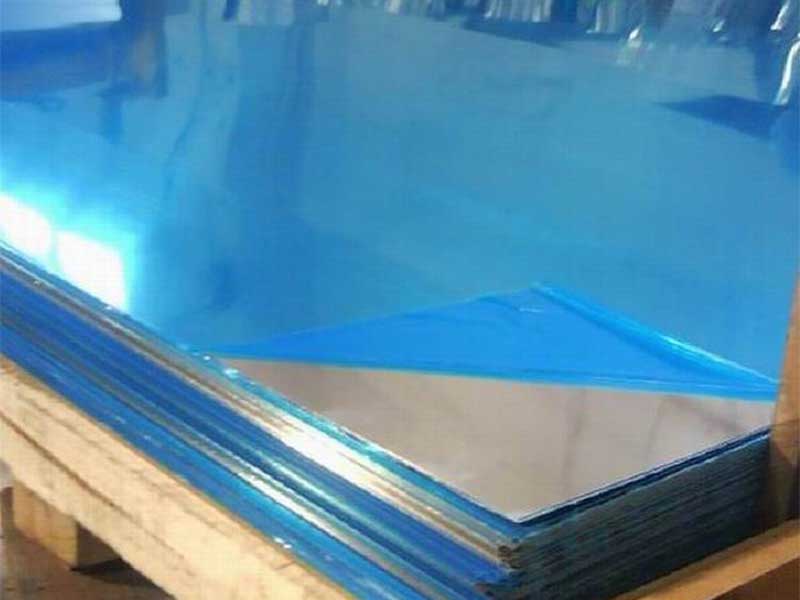

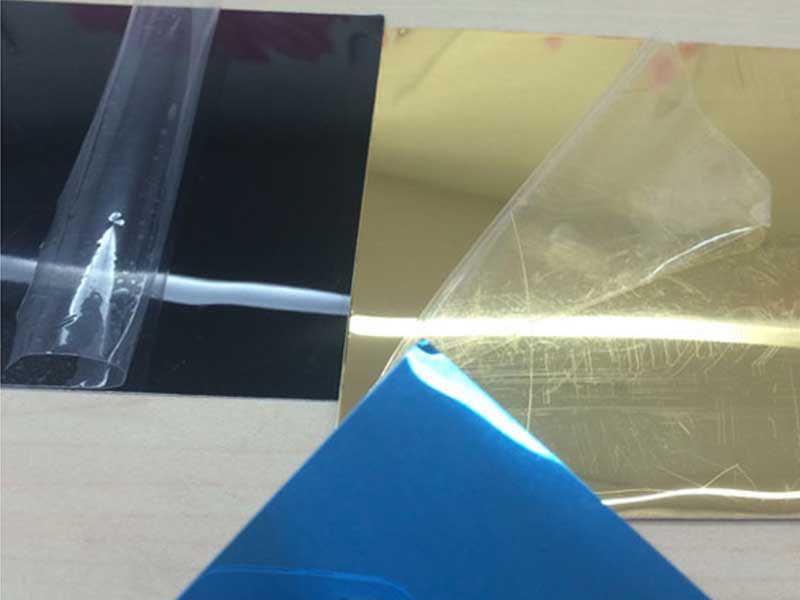

Working with 1100, 1050, 1060, and 3003 mirror aluminum sheets daily, I've noticed distinct differences beyond their chemical compositions. The 1100 series, while incredibly soft and easy to work with, can be surprisingly delicate during the polishing process. Achieving a truly flawless mirror finish requires meticulous attention to detail and careful control of the abrasive stages; even slight inconsistencies in pressure can lead to blemishes. The higher manganese content in 3003, on the other hand, gives it a slightly better strength-to-weight ratio, making it more resistant to scratching during handling and transportation, although it often requires a slightly different polishing technique to achieve the same reflectivity. This is something our newer technicians frequently struggle with, the nuances of each alloy's response to different abrasives and polishing compounds.

Interestingly, the subtle variations in the final mirror finish between these alloys are often more than just aesthetics. For example, the slightly higher reflectivity of a perfectly polished 1050 sheet, compared to a 3003, might be crucial in specific applications like solar reflectors where maximizing light capture is paramount. Conversely, the improved formability of 1100 might be preferred for complex, curved mirror components. these subtleties – the subtle color shifts, the varying degrees of scratch resistance, and even the different ways they react to cleaning solutions – is

-

Alloy 1100: Known for its superb corrosion resistance and formability, 1100 belongs to the commercially pure aluminum category. It’s widely regarded for applications where weathering and weldability are paramount. Plus, at 99% purity, it’s as close to the elemental form of aluminum as you can get, which is why it makes for a glossy mirror finish that's also light as a feather.

-

Alloy 1050: Similar to 1100, 1050 is another purist which offers slightly modified properties suitable for specific uses. Known for its excellent corrosion resistance and high thermal conductivity, 1050 is an often-overlooked gem in the world of mirror aluminum. If you’ve got a heating application in mind, this could be your go-to alloy since it can disseminate heat delightful fast.

-

Alloy 1060: Now we’re getting to an alloy that starts to bring some muscle! With aluminum content above 99.6%, 1060 boasts excellent electrical conductivity. It's the wrestler of the group, fighting heavy duties such as in insulation for transformers and capacitors. Plus, whether polished or mirrored—1060’s shiny façade has found its way into everything from shop fixtures to architectural features.

-

Alloy 3003: Rounding off our quartet is 3003, which isn’t shy about showing off its versatility. Its strength comes from adding manganese, which gives it a solid reputation in the fabrication world, particularly within the food industry. Think of 3003 as your hardworking cousin; it’s perfect for high-strength applications such as pressure vessels and milk trucks, all while sporting that lovely mirror shine.

Shine On! Applications and Functions

Each alloy showcases its charm across various industries:

-

Architectural Elegance: Ever noticed that restaurant you keep going back to? Often, the flashy interiors utilize mirror-finished aluminum sheets from the 1050 or 1060 families, reflecting more than just your lovely face—they project style and sophistication!

-

Interior Design: Modern homeowners are increasingly favoring the reflective properties of aluminum in splashbacks and statement pieces. Merging minimalist design with functionality, 3003 doesn’t shy away from sitting alongside that trendy granite countertop.

-

QUEENS of the Kitchen: Speaking of robust, efficient uses—mirror foil versions of these sheets work wonders in the culinary scene. Think about it! 3003, with its higher durability, is prime for kitchen spaces, making your favorite appliance not just functional but pretty!

-

Automotive Marvels: Who knew that these shiny sheets could contribute to car design? The lightweight shine helps amplify aesthetics while offering durability to vehicles; it's a perfect blend of form and function!

Final Thoughts: Reflecting on the Future

So, next time you see that sleek, shiny aluminum surface, remember the unsung heroes behind each glimmer—their specifics play pivotal roles in countless industries. Be it the super-flexible 1100, the hot-tested 750, the electric-conductor superstar 1060, or the working-class champ 3003, they hold character beyond their shine.

Mirror aluminum sheets aren’t just there to look pretty—each alloy offers functionality tailored to specific needs while bringing a bit of reflective joy into our lives. So go on and embrace those gleaming surfaces with all the enthusiasm they deserve; these alloys might just knock your socks off with their multifaceted charm!

https://www.al-alloy.com/a/1100-1050-1060-3003-mirror-aluminum-sheets.html