Anodized polished finish mirror aluminum coil

When it comes to materials that offer both aesthetic appeal and remarkable functionality, anodized polished finish mirror aluminum coils stand out. These dynamic sheets combine the reflective qualities of aluminum with the enhanced durability that anodizing provides. In this article, we will explore the advantages, applications, and unique properties of anodized polished finish mirror aluminum coils.

Understanding Anodized Polished Finish Mirror Aluminum

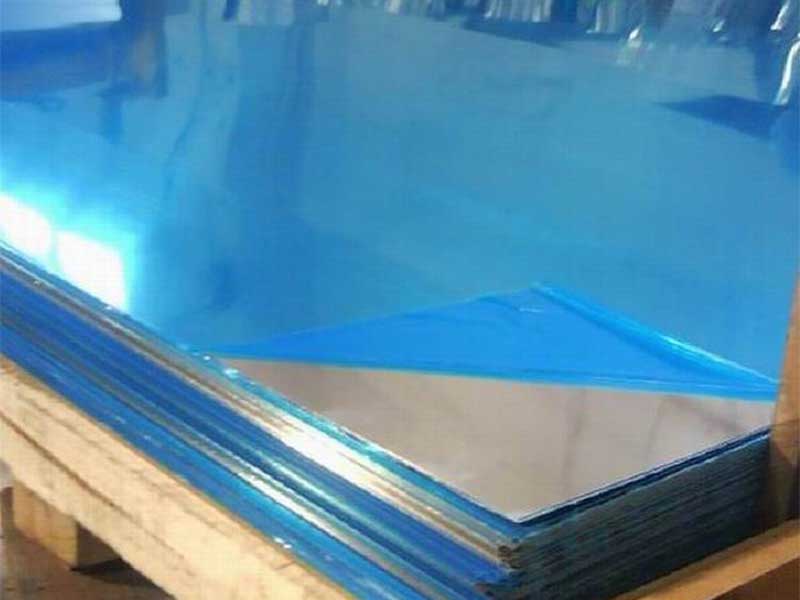

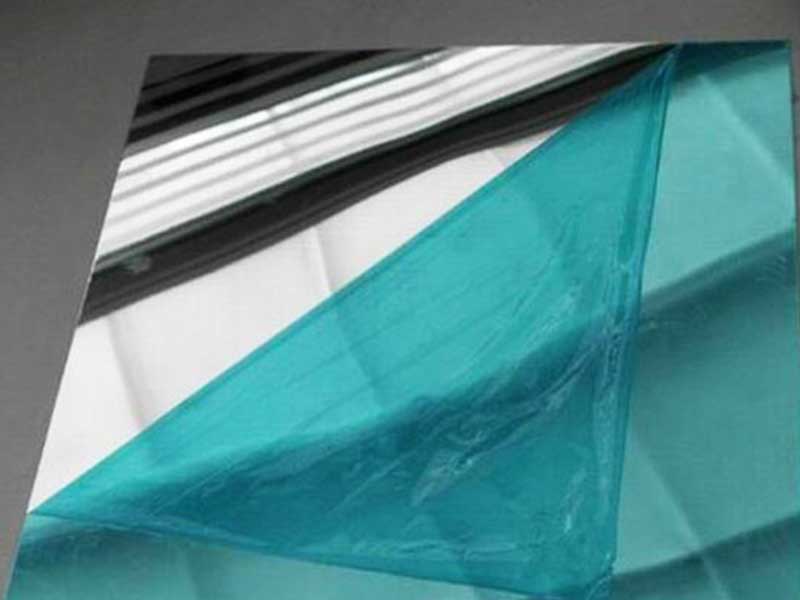

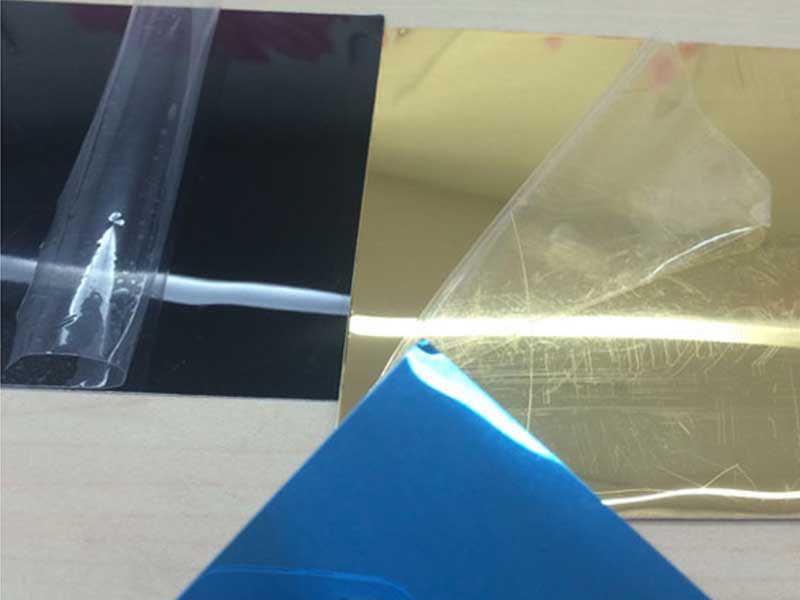

Anodization is an electrochemical process that converts the metal surface into a decorative, durable, corrosion-resistant, anodic oxide finish. In the case of aluminum coils, anodizing not only enhances the natural reflectivity of the aluminum but also promotes a smooth, polished surface that is visually striking. The mirror-like finish serves various purposes, from decorative to practical, making it an essential material in numerous industries.

Benefits of Anodized Polished Finish Mirror Aluminum Coils

-

Enhanced Durability: The anodization process increases the hardness and corrosion resistance of aluminum, making it suitable for both indoor and outdoor applications. This durability ensures that the surface retains its luster for an extended period, even in harsh environmental conditions.

-

Aesthetic Appeal: The polished finish gives the aluminum a reflective quality, reminiscent of a mirror. This makes it an excellent choice for architectural applications, interior design, and signage, where visual impact is crucial.

-

Lightweight Nature: Aluminum is known for its lightweight characteristics. This makes anodized polished finish mirror aluminum coils easy to install and handle, reducing labor costs and improving efficiency in projects.

-

Ease of Maintenance: Thanks to the anodized surface, these coils are easier to clean and maintain than raw aluminum. For industries seeking to maintain a pristine appearance, this quality is invaluable.

-

Environmental Resistance: Anodized aluminum is resistant to staining, scratching, and tarnishing, making it an ideal choice for various applications in environments exposed to moisture, UV radiation, and even chemicals.

Applications of Anodized Polished Finish Mirror Aluminum Coils

Architectural Applications

The stunning reflective properties of anodized polished finish mirror aluminum coils make them popular in modern architecture. They are often used in building facades, interior wall panels, elevators, and decorative elements. Designers appreciate how they enhance natural lighting and contribute to contemporary aesthetics.

Automotive Industry

In the automotive sector, these aluminum coils are ideal for decorative trim, interior components, and exteriors that require both elegance and durability. The reflective quality not only adds luxury but also improves visibility.

Appliances and Electronics

From household appliances to high-end electronics, anodized polished aluminum is favored for its clean lines and modern appearance. Manufacturers utilize it to create sleek surfaces that resist fingerprints and scratches.

Furniture Design

The versatility of anodized polished finish mirror aluminum extends to furniture design, where it is frequently used in both residential and commercial settings. The material gives a high-end look and stands up to the rigors of everyday use.

Choosing the Right Supplier for Your Anodized Polished Finish Mirror Aluminum Coils

When selecting a supplier for anodized polished finish mirror aluminum coils, it is essential to consider the quality of the product, customer service, and the company’s reputation in the industry. Look for manufacturers that provide a variety of options in thickness and finish, ensuring you find the perfect match for your project's specifications.

https://www.al-alloy.com/a/anodized-polished-finish-mirror-aluminum-coil.html