Thickness 0.3mm 0.4mm 0.5mm mirror polished aluminum sheet

Mirror polished aluminum sheets have gained significant acclaim in various sectors due to their unique aesthetic appeal and highly functional characteristics. Manufactured to precise thicknesses such as 0.3mm, 0.4mm, and 0.5mm, these sheets exhibit exceptional reflectivity, making them an outstanding choice for numerous applications. Given their balanced combination of lightweight nature, corrosion resistance, and ease of fabrication, it’s intriguing to examine how these variations in thickness impact their application potential.

Technical Details

At the heart of every high-quality mirror finished aluminum sheet are technical specifications that enhance its functionality. The 0.3mm, 0.4mm, and 0.5mm thick sheets are crafted using an aluminum alloy, often 1050 or 1060, selected for its excellent formability and strength.

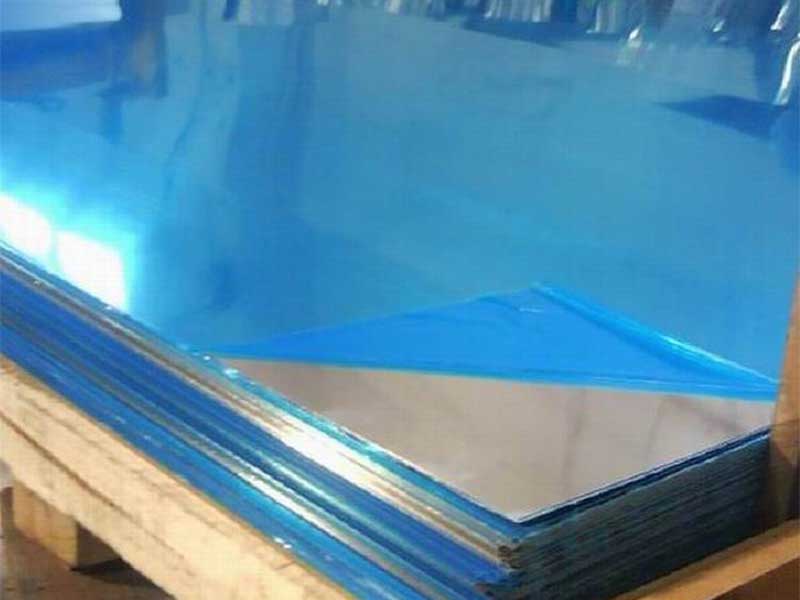

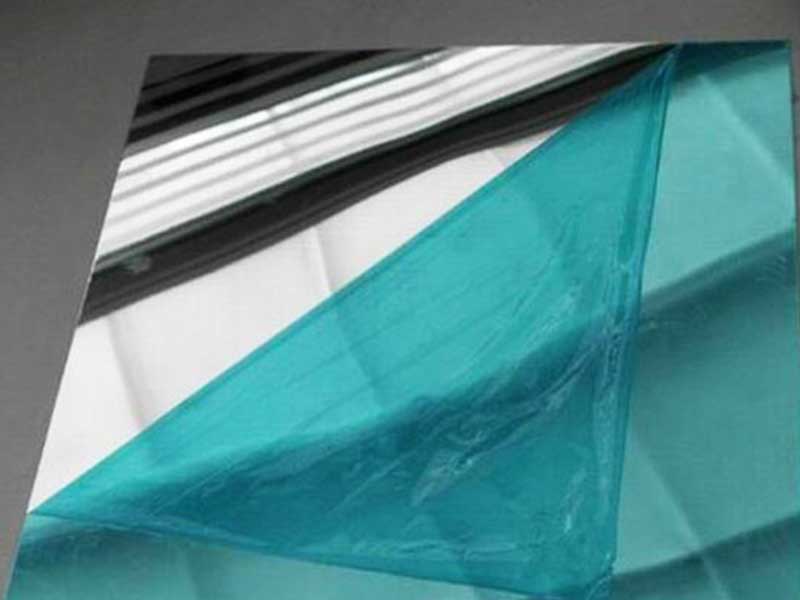

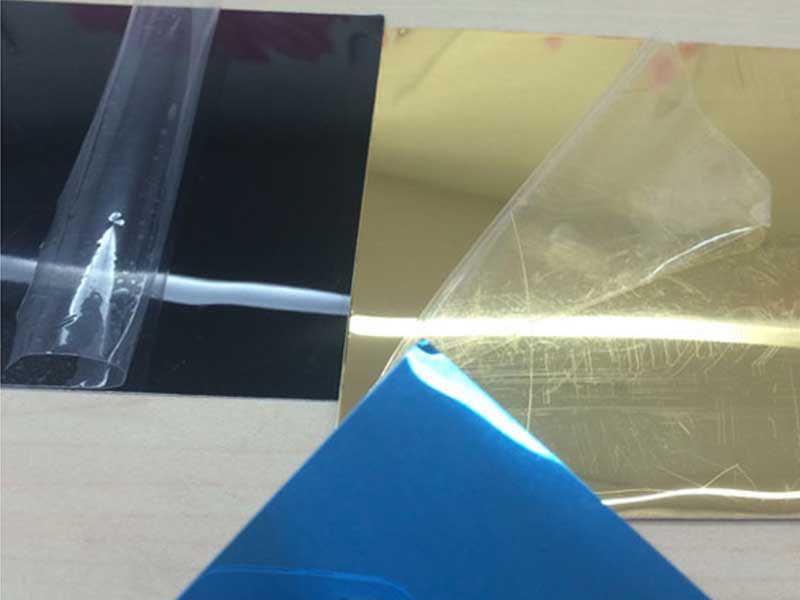

Working with 0.3mm, 0.4mm, and 0.5mm mirror polished aluminum sheets presents a unique set of challenges compared to thicker gauge materials. The thinner sheets are incredibly delicate; even minor mishandling can lead to scratching, bending, or even tearing. This necessitates specialized handling procedures throughout the production process, from the initial rolling and polishing stages to packaging and shipping. We utilize specific tooling and jigs to minimize deformation and ensure consistent quality. The incredibly smooth, reflective surface, while aesthetically desirable, is also highly susceptible to fingerprints and smudges, requiring cleanroom-like conditions during final inspection and packaging. Maintaining a consistent, high-quality mirror polish across such thin gauges is a constant balancing act between polishing aggressiveness and material removal.

Furthermore, the inherent flexibility of these thin sheets influences design considerations for our clients. While they offer lightweight advantages and can be easily formed into complex shapes, the risk of warping or buckling under stress is significantly higher than with thicker materials. We therefore often spend time consulting with clients on appropriate design choices to ensure their finished product meets both aesthetic and structural requirements. The thinner gauges also present challenges in certain applications, such as those requiring higher rigidity or resistance to impact. these limitations and providing comprehensive technical support to our customers is crucial to ensuring their success and our reputation for providing high-quality mirror aluminum sheet.

- Reflective Finish:

- Each product undergoes a stringent polishing procedure that creates its distinctive mirror finish. The surface achieves a Y-value (reflective quality) greater than 90%, which is pivotal in many applications where visual appeal is paramount.

- Temper Options:

- These sheets commonly come in temper states like H24 (partially hard) and H22 (strain-hardened), granting added tensile strength while maintaining the malleability required for bendingommersatz enn gemakkelijker forms.

- Durability:

- Lighter in weight, the sheets in these thicknesses combine aluminum’s inherent corrosion resistance with physical robustness, suitable for various environmental conditions ranging from humid areas to even saltwater locations when appropriately treated.

Applications Galore

Each thickness contributes uniquely to the adaptability of mirror aluminum sheets in specific industries.

-

0.3mm Mirror Aluminum Sheet: This thin profile is perfect for applications requiring detailed lightweight components. Its use is prevalent in signmaking and decorative elements for interiors, such as:

-

Interior Design: Wall cladding, ceilings, backlit signage, and artworks distribute light evenly while enhancing aesthetic depth—perfect for high-end retail spaces.

-

Transportation: Introduced into automobiles and trailers, where list feed fabricators often use lighter components for added fuel efficiency without compromising visual design.

-

0.4mm Mirror Aluminum Sheet: A mid-range sheet, ideal for scenarios requiring minimal additional durability. Its utility extends to:

-

Appliance Manufacturing: Items such as refrigerator doors, washer or dryer facades benefit from the polished surface that combines functionality with elegance. It adds a modern touch while reflecting light.

-

Commercial Lighting: Reflector applications in lighting fixtures achieve innovative designs, maximizing light distribution in stores, galleries, and workplaces.

-

0.5mm Mirror Aluminum Sheet: Representing resilience with added thickness, this option provides a higher degree of durability, accommodating more robust applications such as:

-

Architectural Projects: Large installations in external facades or dramatic restorations benefit from thicker aluminum sheets’ robustness, able to withstand weather elements without sacrificing aesthetics.

-

Transportation Sector: Bus accessories and trailers utilizing this thicker sheet benefit from increased structural support allowing for more versatility in design while reducing weight per unit area efficiently.

https://www.al-alloy.com/a/thickness-03mm-04mm-05mm-mirror-polished-aluminum-sheet.html