Aluminum sheet finishes

Aluminum sheets are ubiquitous in various industries—from aerospace engineering to everyday household products—but one might wonder what goes beyond their inherent strength and lightweight characteristics. The answer often lies in the finishes applied to these aluminum sheets, a process that marries functionality with aesthetics. Let's take an insightful journey into the world of aluminum sheet finishes, looking at how they enhance not only performance but also the desirable appearance in architectural applications.

More Than Meets the Eye

When you pick up an aluminum sheet, your immediate reaction may be to see it simply as a solid piece of metal. However, the truth is that each finish applied to the surface can serve multiple purposes, encapsulating a narrative that goes beyond its appearance. The physical characteristics of a finish—whether matte, shiny, smooth, or textured—play a vital role in how the aluminum interacts with its environment.

Types of Aluminum Sheet Finishes

-

Anodized Finish Anodizing is a process that deliberately oxidizes the surface of aluminum to create a more wear-resistant layer. This finish enhances the corrosion resistance of the alloy while allowing the material to take on various colors through dyeing processes. For industries designing for design appeal, anodized surfaces can transform functional structures into interactive art pieces.

-

Painted Finish A painted finish distinguishes itself by offering both protection and vast color options. This process uses a liquid or powder coat, making the aluminum sheets highly versatile for customized external appearances while ensuring resistance to dirt, moisture, and UV rays. This makes painted finishes a go-to choice for architectural applications where visual appeal and durability are non-negotiable.

-

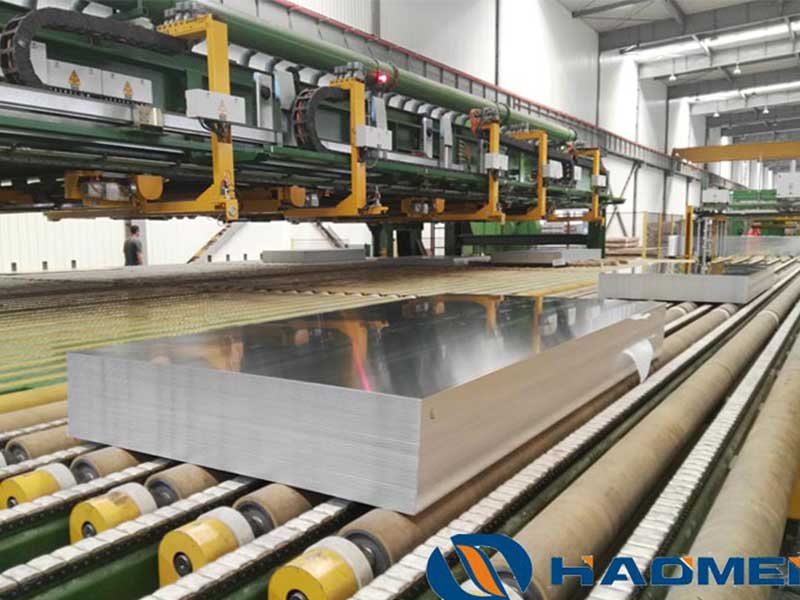

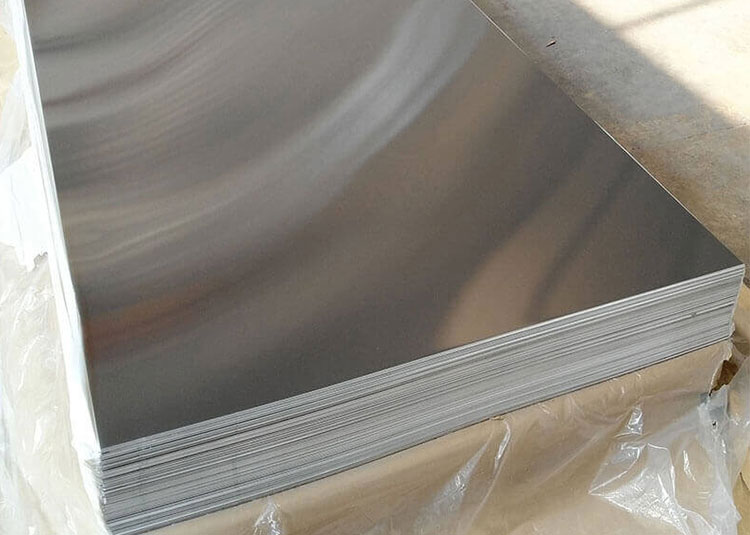

Mill Finish Recognized as the standard default finish, mill finishes involve little to no extra processing. They offer a sleek, reflective finish but without added coloring or coatings. This raw aesthetic serves many architectural and industrial applications, providing an industrial vibe that some designers embrace, advocating for authenticity in their works.

-

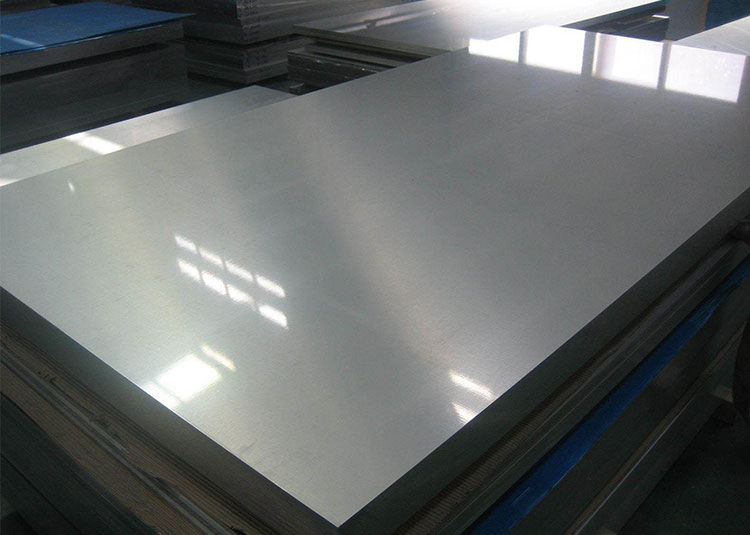

Brushed Finish With the brushed technique, a mechanical process generates a consistent pattern across the sheet's surface, which not only detracts potential scratches but adds a tactile quality. In the age of interaction with surfaces in landscapes and interiors, offering both visual intrigue and tactile experience elevates brushed finishes to a fundamentally preferred choice.

-

Mirrored Finish Reflective surfaces serve a purpose much deeper than enhancing light within spaces. Unique to high-end architecture, mirrored finishes can dictate the relationship between seen and unseen and blur compositions within a landscape. Here, aluminum transcends mundane industrial connotations and invites conceptual possibilities that can inspire today's urban designs.

Not Just Surface Deep

While many might perceive finishes as mere protective coatings, they are fundamentally about creating sensory experiences and evoking emotions. A brushed finish might convey rugged charm, while a polished one speaks of refinement. As we evolve toward a world that heavily prizes sustainability, using high-performing finishes allows for versatility without compromising environmental conscience.

The variations in aluminum sheet finishes exhibit an ability to adapt distinctive personalities to each project, making it paramount for designers and architects to appreciate these nuances. Ultimately, the choice of finish influences not just aesthetic appeal, but also longevity, resilience, and functionality of the final product.