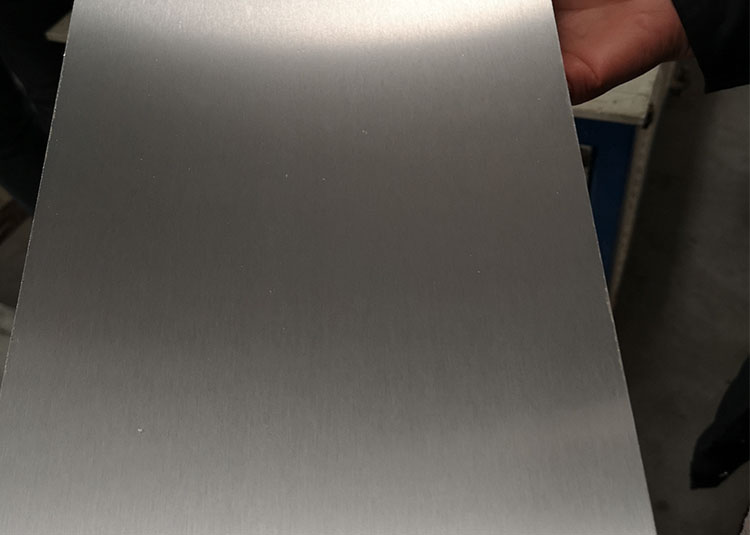

Brushed aluminum plate

Brushed Aluminum Plate: An Intricate Fusion of Aesthetics and Functionality

Aluminum has long been celebrated for its lightweight, robust properties and resistance to corrosion, making it a choice material for many industries. However, when it comes to refining the capabilities of aluminum in design and utility, brushed aluminum plates elevate this versatile metal to new heights. They feature a remarkable textural quality achieved through a polished technique that instills both aesthetic appeal and enhanced characteristics—"brushed" is not solely a design choice but a transformation that introduces numerous functional benefits.

The Art and Science of Brushing Aluminum

Brushed aluminum undergoes a specialized finishing process, where fine scratches or surface lines are produced on the aluminum plate. Achieving this surface finish involves mechanical pads or brushes making contact with the surface of the aluminum, resulting in a consistent and uniform texture. This process not only revolutionizes the physical aspects of the aluminum but enhances its functionality too:

-

Enhanced Light Reflection: The linear texture of a brushed surface diffuses light, offering a lively sheen that creates an eye-catching allure without being overly reflective.

-

Finger Print Resistance: This characteristic texture also combats the evident evidence of fingerprints or smudges, making brushed aluminum plates suitable for high-traffic areas where aesthetics need to be preserved.

-

Improved Abrasion Resistance: The brushed surface can withstand heat and physical wear better than standard finishes, elongating the lifecycle of materials—an essential quality in demanding environments.

Diverse Applications of Brushed Aluminum Plates

From commercial establishments to equipment design, the utility of brushed aluminum plates spans multiple sectors, showcasing its multifaceted capabilities:

-

Architectural Features: Clean lines and modernity often drive the architectural aesthetics; brushed aluminum plates serve as unique claddings for buildings or as design elements for internal fixtures. Their durability ensures they maintain structural integrity while highlighting design sophistication.

-

Consumer Electronics: Products ranging from gadgets to sophisticated computing devices frequently harness brushed aluminum. This technical choice not only contributes to its lightweight construct but also presents a high-tech vitality appealing to most consumers.

-

Transportation: Lightweight aluminum structures prevail within the automotive and aerospace engineering domains. However, the brushed finish's tactile qualities enhance car interiors while simultaneously providing necessary durability on exteriors.

-

Railway and Marine Applications: The inherit resistance to seawater and a steady maintenance ethos makes brushed aluminum plates industrious. Its integration into everything from railway fixtures to boat fittings offers industries non-compromising functionality while elevating aesthetics.

Technical Specifications to Consider

While not overly complex, certain specifications merit attention that affects performance negatively or positively based on project requirements. The alloy series—most brushed aluminum for commercial use stems from either Series 5000 or 6000 due to their increased strength and suitability for twisting, forming, and cutting now facilitates various custom applications.

It's also crucial to evaluate the gauge or thickness of the aluminum plate selected for specific applications. Significantly heavier plates lend usable impact rigidity, while lighter gauges can closely align from a manufacturing standpoint with flexible operational aspects.