Introduction:

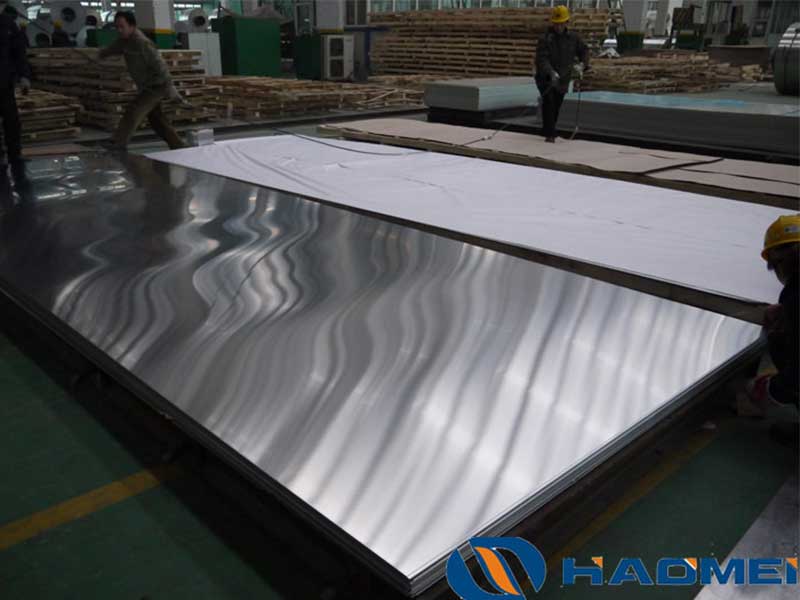

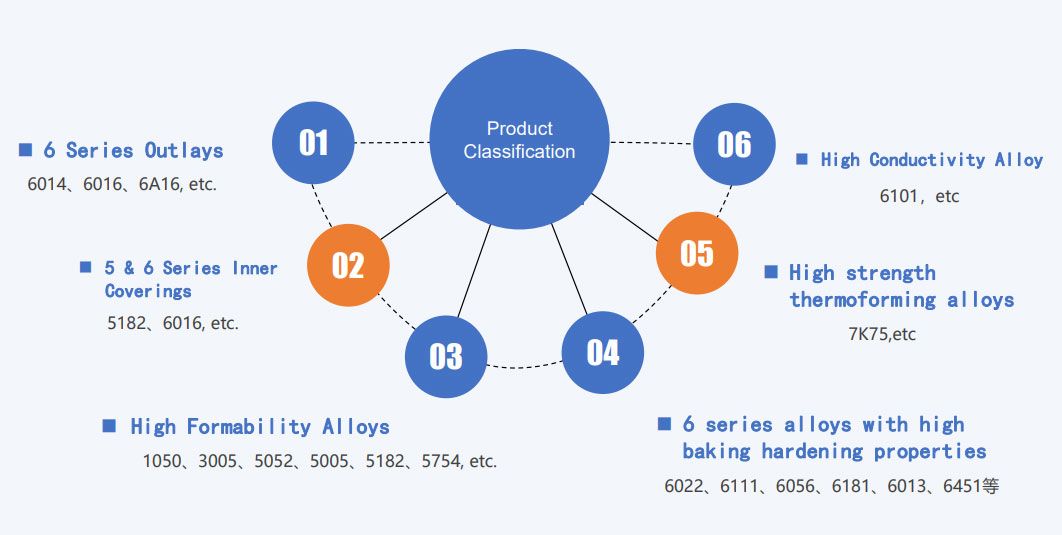

The automotive industry is constantly evolving, with manufacturers striving to develop vehicles that are not only high-performing but also environmentally sustainable. In this pursuit, aluminum sheet has emerged as a key material for automotive applications. Its unique properties and versatility make it an ideal choice for various components, offering numerous benefits in terms of performance, fuel efficiency, and sustainability.

Features:

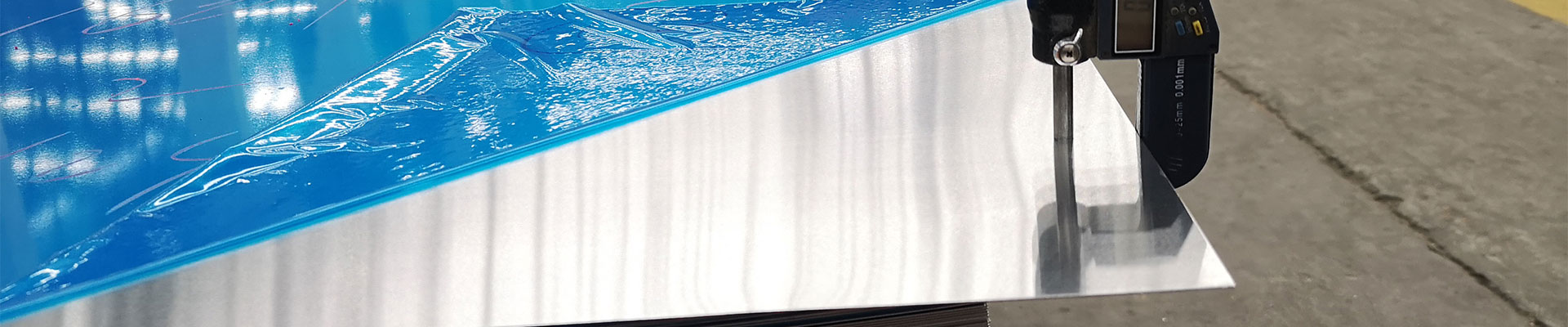

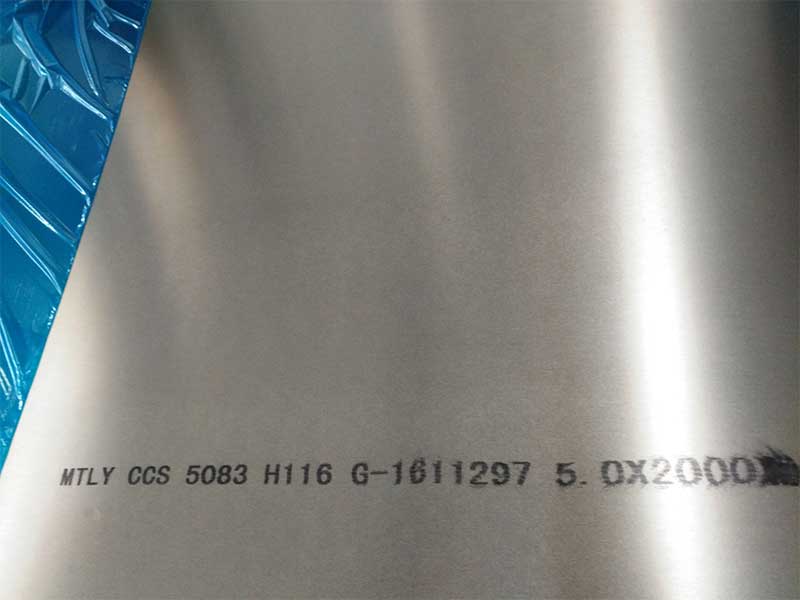

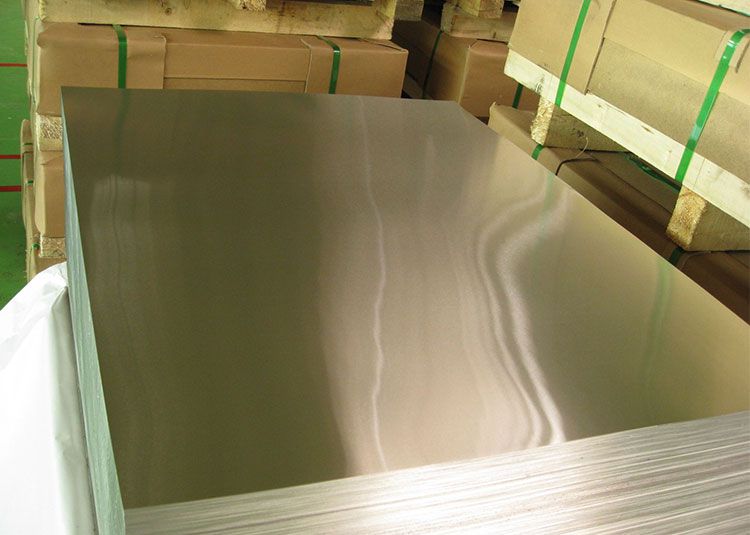

1. Lightweight and Strength:

One of the primary advantages of aluminum sheet is its exceptional strength-to-weight ratio. Aluminum is significantly lighter than traditional steel, enabling automakers to reduce the overall weight of vehicles without compromising structural integrity. This reduction in weight translates into improved fuel efficiency, as lighter vehicles require less energy to propel. Additionally, the lightweight nature of aluminum sheet enhances handling and maneuverability, resulting in a more enjoyable driving experience.

2. Enhanced Safety:

While aluminum is lighter than steel, it does not compromise on safety. Aluminum sheet is engineered to provide high levels of crashworthiness, ensuring the protection of vehicle occupants. Its ability to absorb and dissipate energy during impacts makes it an excellent choice for manufacturing automotive components such as crash boxes, door beams, and bumpers. By utilizing aluminum sheet, automakers can enhance vehicle safety without adding unnecessary weight.

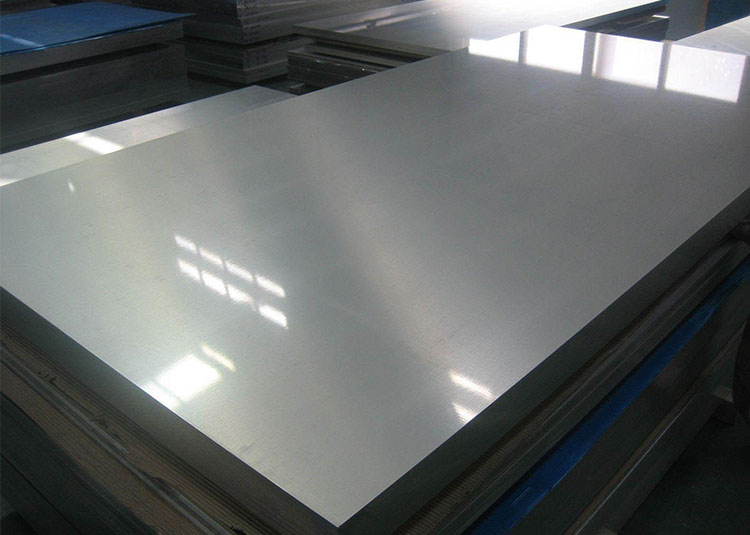

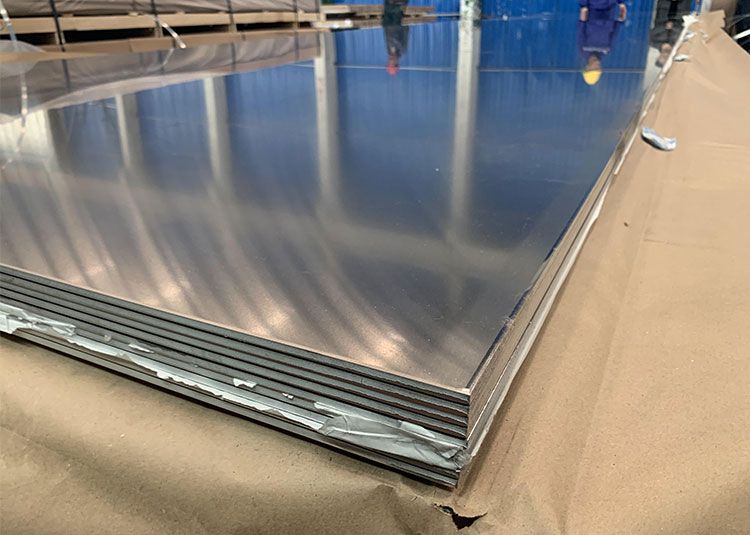

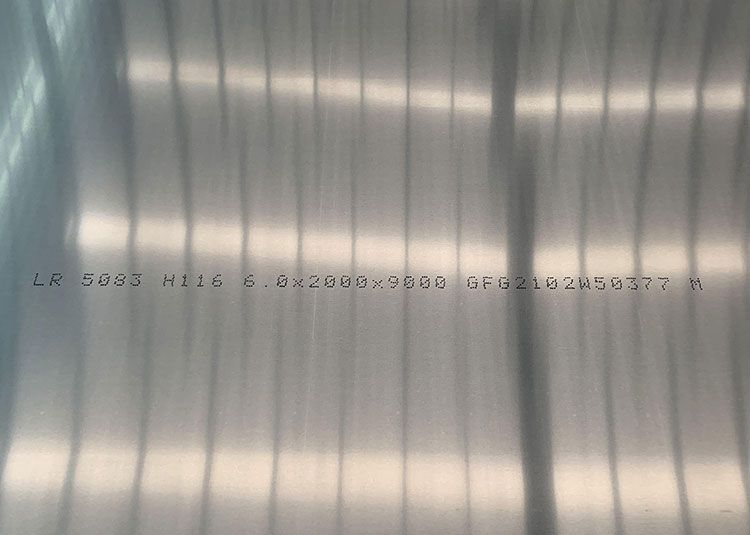

3. Corrosion Resistance:

Aluminum possesses excellent corrosion resistance properties, making it highly suitable for automotive applications. Unlike steel, aluminum does not rust, ensuring the longevity and durability of vehicle components. This resistance to corrosion significantly reduces maintenance costs and extends the lifespan of automotive parts, contributing to long-term sustainability.

4. Recyclability:

The automotive industry is increasingly focusing on sustainability, and aluminum sheet plays a crucial role in achieving this goal. Aluminum is 100% recyclable without losing its properties, making it an infinitely sustainable material. Recycling aluminum requires only a fraction of the energy needed for primary production, resulting in reduced greenhouse gas emissions. By utilizing aluminum sheet, automakers contribute to the circular economy and minimize the environmental impact of their vehicles.

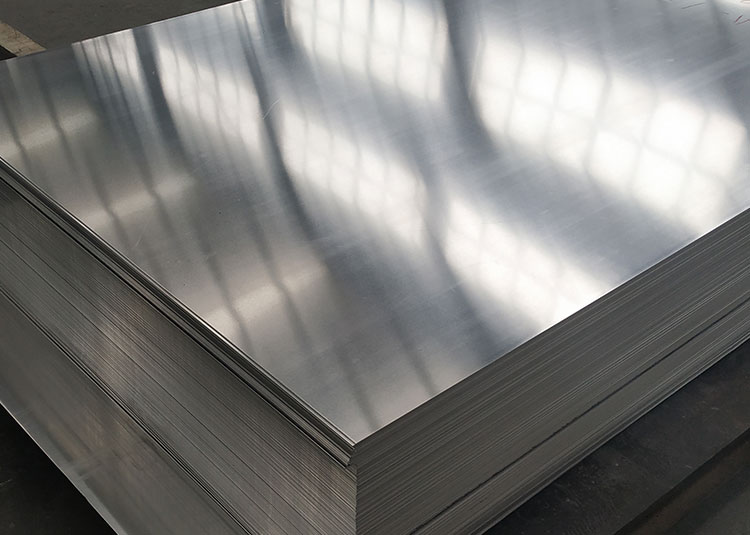

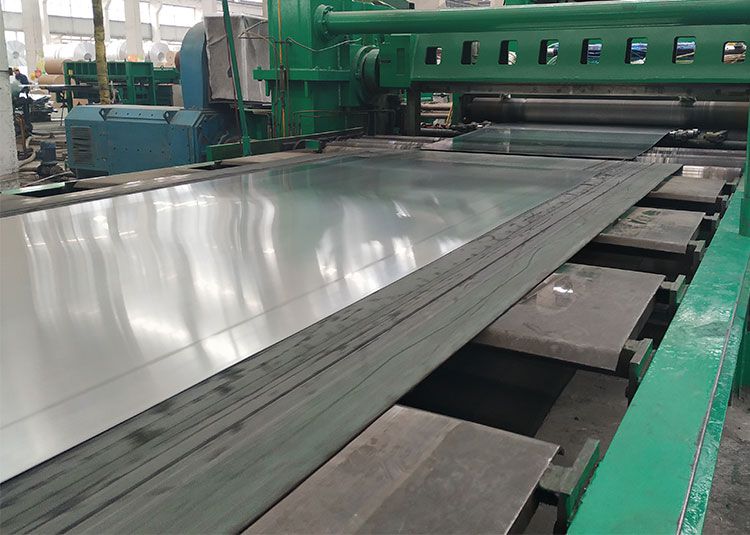

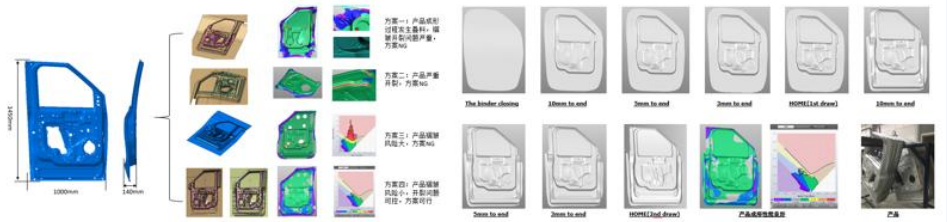

5. Design Flexibility:

Aluminum sheet offers design flexibility, allowing automakers to create innovative and aerodynamic vehicle designs. Its malleability enables the production of complex shapes, improving aerodynamic performance and reducing drag. The ability to form aluminum into intricate designs also facilitates the integration of various functionalities, such as improved heat dissipation and noise reduction. This design flexibility not only enhances the overall aesthetics of vehicles but also contributes to their overall performance and efficiency.

The use of aluminum sheet in the automotive industry has revolutionized vehicle manufacturing. Its lightweight nature, combined with exceptional strength, enhances performance and fuel efficiency. Moreover, its corrosion resistance and recyclability contribute to long-term sustainability, aligning with the industry's growing focus on environmental responsibility. With its design flexibility, aluminum sheet allows automakers to create innovative and aerodynamic vehicles that meet the demands of modern consumers. As the automotive industry continues to evolve, aluminum sheet will undoubtedly play a vital role in shaping the vehicles of the future.