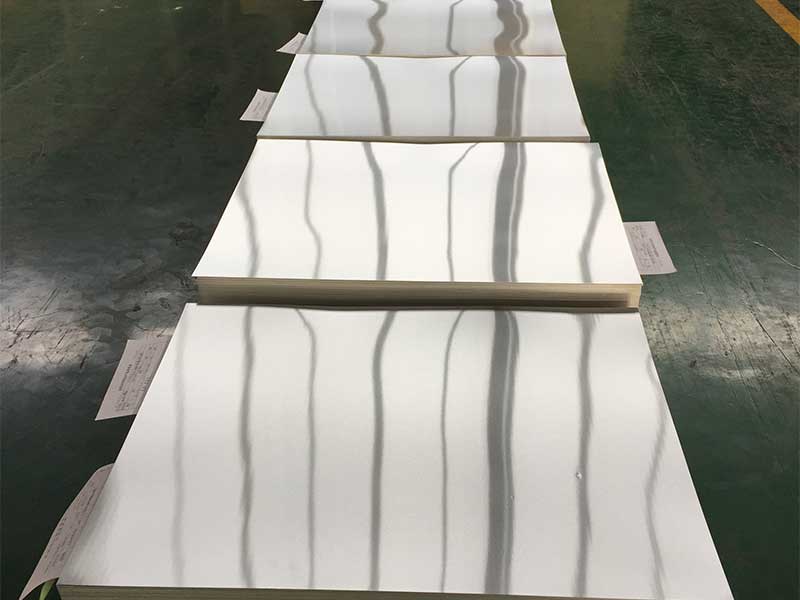

1100 aluminum sheet

Aluminum has become a cornerstone material across multiple industries due to its versatility and lightweight properties. Among the various types of aluminum available in the market, 1100 aluminum sheet stands out due to its unique attributes that cater to a plethora of applications.

Features of 1100 Aluminum Sheet

1. High Corrosion Resistance

One of the most significant features of 1100 aluminum sheet is its excellent resistance to corrosion. This property makes it an ideal choice for manufacturing parts that will be exposed to harsh conditions, including chemical environments and pollutants. The thin oxide layer that forms on the surface protects it from corrosion, meaning that products made from this alloy can maintain their integrity over time.

2. Excellent Workability

1100 aluminum sheet boasts remarkable workability; it can be easily formed, drawn, or spun. This attribute is invaluable for manufacturers, as it allows for intricate designs and components without compromising the material's strength. Whether you’re pressing, rolling, or machining, 1100 aluminum sheet performs exceptionally well, facilitating a seamless production process.

3. Lightweight

In comparison to other metals, aluminum is notably lighter, and 1100 aluminum sheet embodies this advantage. This lower density is highly sought after in several applications where reducing weight is crucial, such as in aerospace components, automotive parts, and even packaging materials.

4. Thermal and Electrical Conductivity

Another outstanding characteristic of 1100 aluminum sheet is its superior thermal and electrical conductivity. With a conductive capacity that makes it suitable for heat exchangers and electrical applications, this material becomes an appealing option for manufacturers looking for properties that facilitate efficient thermal regulation and electrical performance.

5. Soft and Ductile

Unlike other aluminum alloys, which may feel rigid, 1100 aluminum sheet is relatively soft and ductile. This ductility enables the material to be manipulated into various shapes and sizes easily, enabling more dynamic design possibilities for a multitude of applications.

Applications of 1100 Aluminum Sheet

1. Food and Chemical Handling

Given its excellent corrosion resistance, 1100 aluminum sheet is frequently used in applications involving food and chemical handling. It is widely utilized in storage tanks, transport containers, and food processing equipment, ensuring that products remain safe and uncontaminated during handling.

2. Transportation Industry

The lightweight nature of 1100 aluminum sheet makes it a valuable asset in the transportation sector, including automotive and rail vehicles. Its ability to reduce overall weight contributes to improved fuel efficiency and maneuverability, making it an essential component in the design of various transportation systems.

3. Electrical Applications

With impressive electrical conductivity, this aluminum sheet is often found in electrical components such as heat sinks, lighting fixtures, and communication equipment. Its efficacy helps optimize the performance of electrical devices, enhancing overall productivity.

4. Architectural Features

The design flexibility offered by the abrasion and corrosion resistance of 1100 aluminum sheets makes it an excellent choice for architectural features. From decorative façades and siding to roofing solutions, this aluminum is often used to create stylish and durable building additions while also being energy efficient.

5. Packaging

Due to its pliable characteristics, 1100 aluminum sheets are popularly used in packaging applications. Their lightweight and capability to be easily formed make them ideal for creating containers, foil, and wraps, which also assist in protecting contents from moisture and air.