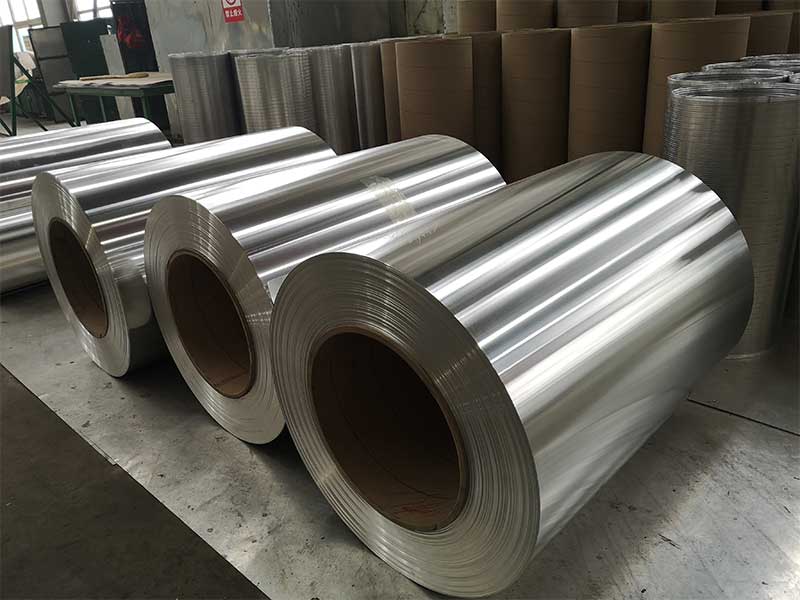

Aluminum coil 5005 5052 5754 5083

Aluminum Coils: A Look at Grades 5005, 5052, 5754, and 5083

Aluminum coils are materials used in an array of industries due to their exceptional properties, such as corrosion resistance, lightweight, and malleability. Among the various grades of aluminum coils, 5005, 5052, 5754, and 5083 is know due to their specific mechanical and chemical properties.

Working with aluminum coils 5005, 5052, 5754, and 5083 daily reveals distinct processing nuances. 5052, with its higher manganese content, exhibits exceptional corrosion resistance, making it ideal for applications demanding longevity like marine or chemical processing. However, its slightly lower strength compared to 5083 necessitates careful consideration during forming operations; aggressive bending could lead to cracking. Conversely, 5083, prized for its high strength and weldability, can be more challenging to form due to its work-hardening tendencies. We often find ourselves adjusting tooling and speeds to avoid springback and ensure consistent dimensional accuracy. 5005, a workhorse alloy, offers a good balance of strength and formability, while 5754 shines in applications needing superior formability and corrosion resistance, particularly in demanding environments.

the subtle differences in these alloys is crucial for efficient production. For example, surface finish requirements vary; 5052's inherent corrosion resistance might allow for a slightly less rigorous surface preparation compared to 5005. Similarly, the choice of lubricants and tooling influences the final product quality significantly. We’ve seen firsthand how incorrect die design or insufficient lubrication can lead to surface imperfections, particularly galling on 5083, resulting in scrap and production delays. Continuously refining our processes, including precise control of annealing

Aluminum Alloy 5005

Functions and Applications: Aluminum 5005 is known for its excellent corrosion resistance and capability to take up various finishes. It's popular in architectural applications, such as when creating exterior walls and roofs. Additionally, its aesthetic appeal makes it a favorite in decorative hardware and lighting fixtures, often employed in public art installations and signage.

Technical Details: With approximately 1.0% magnesium content, this alloy exhibits low chemical reactivity while remaining formable and weldable. It is available in a wide range of thicknesses and widths, giving designers great flexibility in their applications.

Aluminum Alloy 5052

Functions and Applications: Aluminum 5052 is characterized by its excellent weldability and formability, finding utility within the automotive and marine industries, especially in the construction of fuel tanks, pressure vessels, and hydraulic tubes. The automotive sector also benefits from its lightweight attributes, which enhance fuel efficiency while maintaining strength.

Technical Details: This particular grade offers a high degree of corrosion resistance, especially in marine atmospheres, aided by its significant amount of magnesium content (2.5% to 3.5%). The mechanical strength of 5052 increases with solids delivered by the residual stress created during extensive processing.

Aluminum Alloy 5754

Functions and Applications: Aluminum 5754 is predominantly utilized in shipbuilding and manufacturing vehicle chassis as it boasts an incredible strength-to-weight ratio characteristic. Its lightweight property combines benefit when constructing hulls and other components seamlessly integrated into boats, barges, and floatation devices.

Technical Details: With a magnesium content of approximately 2.6% to 3.6%, Aluminum 5754 resistant to saltwater corrosion, allowing it not only to add practicality but safety in marine operations. While maintaining great toughness as a formed structure, this alloy still retains excellent toughness, a qualification for shipbuilding materials.

Aluminum Alloy 5083

Functions and Applications: Aluminum 5083 is renowned for its high strength, corrosion resistance, and weldability, predominantly used in the marine, automotive, and aerospace industries. Its application extends to critical structures as well, like bridges and buildings where strong α levels are mandated.

Technical Details: With roughly 5.0% to 5.4% magnesium and iron percentages of 0.4% to 1.0%, the material demonstrates unparalleled strength even in harsh climates or marine applications. This advantageous combination of properties further enhances its performance such that it exceeds multiple fabricability standards.

https://www.al-alloy.com/a/aluminum-coil-5005-5052-5754-5083.html