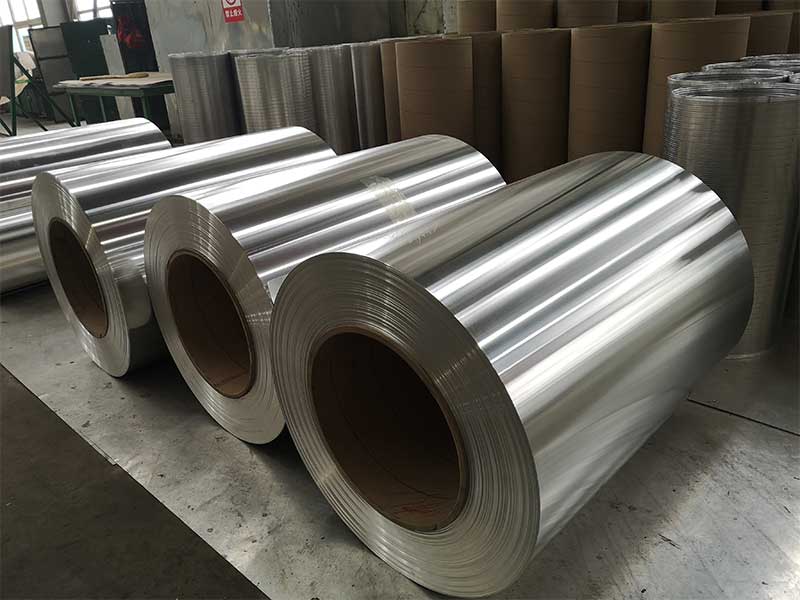

3003 5005 5052 5083 6063 Aluminum Coil

Aluminum coils have become vital resources across numerous industries, offering outstanding strength-to-weight ratios, corrosion resistance, and formability. This article delves into the diverse applications and characteristics of five popular aluminum alloy series: 3003, 5005, 5052, 5083, and 6063.

Understanding Aluminum Alloys

Aluminum alloy designations typically include numbers that indicate different groups and properties. The first digit signals the principal alloying element with which the aluminum is alloyed, while the last two digits indicate alterations made for specific characteristics.

1. 3003 Aluminum Coil

3003 aluminum coil belongs to the 3000 series and is composed mainly of manganese as its main alloying element. This alloy is highly formable, making it ideal for intricate designs and structures where malleability is essential. Key applications of 3003 aluminum coils include:

- Food and chemical handling: Its resistance to corrosion supports sanitary conditions perfect for heating or evaporating aluminum processes.

- Cookware: The workability and non-toxic qualities of 3003 make it an excellent choice for pots, pans, and trays.

2. 5005 Aluminum Coil

5005 alloy aluminum coils are notable for their excellent surface finish and aesthetic appeal—thanks to the addition of magnesium and a small amount of silicon. Its applications are often seen in areas that benefit from the combination of stylish look and good corrosion resistance, including:

- Architectural components: Skylights, wall panels, and custom framing frequently utilize 5005 coils for harmoniously blending durability and design.

- Signage: With rich color results after anodizing, the visual quality of these coils keeps their aesthetic appeal on display.

3. 5052 Aluminum Coil

5052 aluminum coil is firm and shows high resistance to corrosion, especially in marine environments due to the elevated magnesium content. The strength and amazing fatigue resistance also make 5052 highly sought-after in more demanding applications:

- Marine applications: Boat hulls, frames, and other seawater assets leverage 5052's formidable strength and toughness.

- Automotive Industries: Many manufacturers prefer this coil for components aimed at longevity and durability.

4. 5083 Aluminum Coil

5083 aluminum coil is one of the strongest alloys in the aluminum marine circuit and features high resistance to both seawater and atmospheric conditions. This coil is crucial for boats, ships, and other applications that suit its resilience, such as:

- Shipbuilding: The need for lightweight but robust framing guides the use of 5083 aluminum.

- Cryogenic storage tanks: It can effectively handle low-temperature environments further substantiating its relevance in various industries.

5. 6063 Aluminum Coil

Belonging to the 6000 series, 6063 aluminum coil incorporates silicon and magnesium. Characterized by excellent extrusion characteristics, it is primarily known for its graceful finishing when anodized. Here, its applications are extensive:

- Architectural shapes: 6063 coils are crucial for building frames, window frames, and exterior fixtures serving both aesthetics and durability.

- Furniture frames: The aesthetics and flexibility underpinning 6063 make aluminum integrated furniture increasingly popular across modern décor necessities.

Selecting the Right Aluminum Coil for Your Application

When choosing the right aluminum coil, consider the parameters such as mechanical properties, corrosion resistance, aesthetics, and specific project requirements.

Using multitudes across different industries underscores significant choice offers with various perforation, coloration, welding, and joining mechanisms effectively in hand. High-grade aluminum compositions, including 3003, 5005, 5052, 5083, and 6063, provide immense options tailored to distinctive need sets.

https://www.al-alloy.com/a/3003-5005-5052-5083-6063-aluminum-coil.html