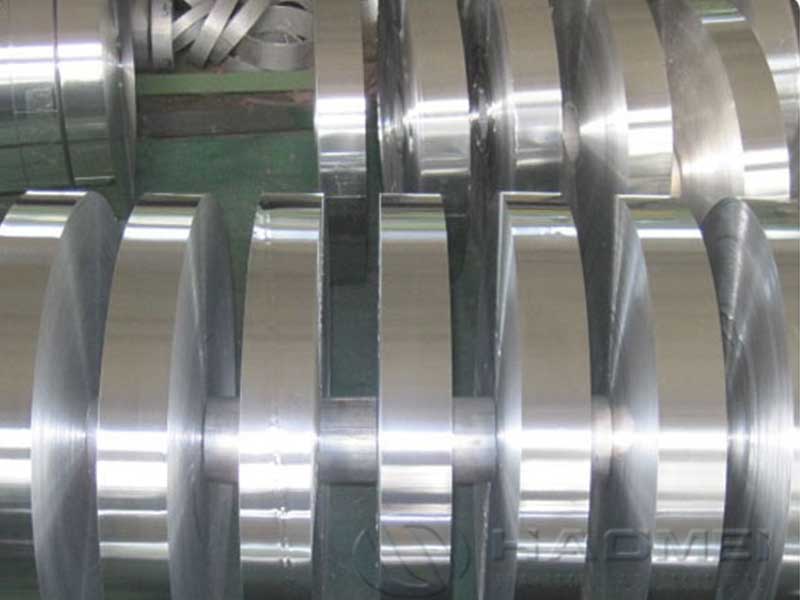

Aluminum foil 1100 H18

The Multifunctional Role of Aluminum Foil 1100 H18: A Unique Perspective

In the vast and dynamic realm of materials science, aluminum foil 1100 H18 stands out not merely as a commonplace kitchen item; it’s a powerhouse alloy with diverse functionality that reaches far beyond the standard culinary uses. this material’s specific properties invites us to explore its unique attributes and wide-ranging applications across numerous industries.

1100 H18 is our workhorse. It's the grade we churn out the most, and honestly, I've developed a sort of grudging respect for it. While not the fanciest or strongest aluminum alloy we produce, its consistency is remarkable. Day in and day out, we can rely on its predictable properties – the slight malleability, the way it responds to the rolling mills, even the subtle sheen it takes on after annealing. I've seen junior technicians struggle with other alloys, getting unexpected results, but 1100 H18 is forgiving. It's like a trusty old machine – sometimes noisy, sometimes demanding, but always reliable in the end. You know what you're getting, which makes troubleshooting a lot easier when things go wrong, something that's hugely important in a high-volume production environment.

The H18 designation always brings to mind the tempering process. That 1/8 hard temper represents a delicate balance. Too soft and it wrinkles too easily during packaging, leading to customer complaints and scrap. Too hard and it becomes brittle, prone to tearing during high-speed applications like food wrapping machines. Finding that sweet spot is what separates skilled operators from the rest. I've spent countless hours tweaking parameters on the tempering line, monitoring the exact temperature and timing to ensure each roll meets the H18 specification. It's a constant dance between

Aluminum Foil 1100 H18

To appreciate aluminum foil 1100 H18, we must first dive into its technical characteristics. Aluminum 1100 is a commercially pure aluminum with an exceptional element of workability. The “H18” temper indicates that it has undergone a cold working process to enhance its strength while providing a fraction of ductility, which renders it more robust compared to its softer counterparts. The unique characteristics lend it a high degree of resistance to corrosion, making it suitable for challenging environments where standard materials may falter.

This typology is typically around 0.006 inches (0.152 mm) thick, enabling its effective use in various applications. With significant chemical resistance and excellent energy conductivity, 1100 H18 strikes a balance between form and functional utility in everyday applications.

Culinary Arts: Beyond Just Baking

While aluminum foil is commonly recognized for its role in kitchens—most of us have used it to wrap leftovers or bake cookies—aluminum foil 1100 H18 escalates this nuance. As a cooking companion, its hardness permits utilizing it in higher heat contexts, adhering comfortably to food items while delivering marination qualities that amplify flavors.

For chefs and culinary experts looking to optimize heat conductivity during slow roasting or broiling, this reference material becomes irreplaceable, as using 1100 H18 enhances even browning and effectively transferring cooking surface heat. Moreover, due to its non-reactive nature, it doesn’t alter the flavor profile of the food, leading to original dining experiences.

Packaging Precision: A Protection Provider

In an era where food preservation is critical for sustainability, the industrial role of aluminum foil 1100 H18 comes to the fore, especially in food packaging. This alloy's durability provides exceptional protection against moisture, oxygen, and light, forming a dependable barrier that extends the shelf life of products.

Think of charcuterie boards wrapped in this aluminum—its airtight sealing keeps off light, preserving flavors and preventing decay better than standard packaging materials. Whether you’re a producer in the pharmaceutical sector requiring sterile packaging or a food vendor needing reliable presentations, aluminum foil 1100 H18 allows for bespoke designs that regulate and boost product longevity.

Industrial Uses: Engineered for Resilience

Outside culinary arts, the industrial applications of aluminum foil 1100 H18 are indispensable. Its superior mechanical properties render it suitable as a component in battery production—contributing to energy storage efficiency, and extending into a variety of telecommunications and thermal management systems.

By providing crucial shielding from fluctuations in temperature, 1100 H18 plays an instrumental role in enhancing device performances while ensuring electronic integrity. Stray electromagnetic interference stays at bay, ensuring reliable operation in communication systems—an example of how nuanced this alloy thrives amid modern-day challenges.

Creativity to Construction: The Flexible Ally

Additionally, aluminum foil 1100 H18 finds utility as an innovative resource in design and manufacturing, with its malleability allowing creative expression—from carvings to large-scale structures needing modest weights and immense pliability. The temporary nature of foils lends itself wonderfully to prototypes where durability matters, enabling artists and engineers alike to experiment and prototype without excessive costs.