Aluminum coil Marine Grade 6063 6061 5754 5083

Aluminum is widely recognized for its lightweight, strength, and corrosion resistance. Among the various grades of aluminum, Marine Grade Aluminum Coils play a crucial role in enhancing the durability and functionality of marine applications. In this elucidation, we will explore the specific features and applications of Marine Grade aluminum coils, including 6063, 6061, 5754, and 5083.

Features of Marine Grade Aluminum Coils

1. Corrosion Resistance

One of the standout features of marine-grade aluminum coils is their exceptional resistance to corrosion, especially in saline environments. The aluminum alloying elements like magnesium and silicon contribute to this property, ensuring that structures remain intact even when exposed to harsh marine conditions.

2. Strength and Durability

Marine-grade aluminum coils are designed to deliver high strength-to-weight ratios. This characteristic allows builders to create lightweight structures without compromising on strength. Alloys 5754 and 5083 provide superior mechanical properties, making them ideal for high-stress components.

3. Weldability

Notably, alloys like 6061 and 5083 are known for their excellent weldability. This property is essential in marine construction for seamless fabrication, enhancing overall rigidity and structural integrity.

4. Formability

Marine-grade aluminum coils can be easily formed into various shapes and designs. This flexibility allows for creative freedom in marine engineering, accommodating various designs from recreational boats to commercial vessels.

5. Non-magnetic

Aluminum is inherently non-magnetic, a feature particularly important in naval operations where magnetic interference could be an issue. This benefit ensures that navigational instruments function efficiently without disruption.

Applications of Marine Grade Aluminum Coils

1. Boat Building

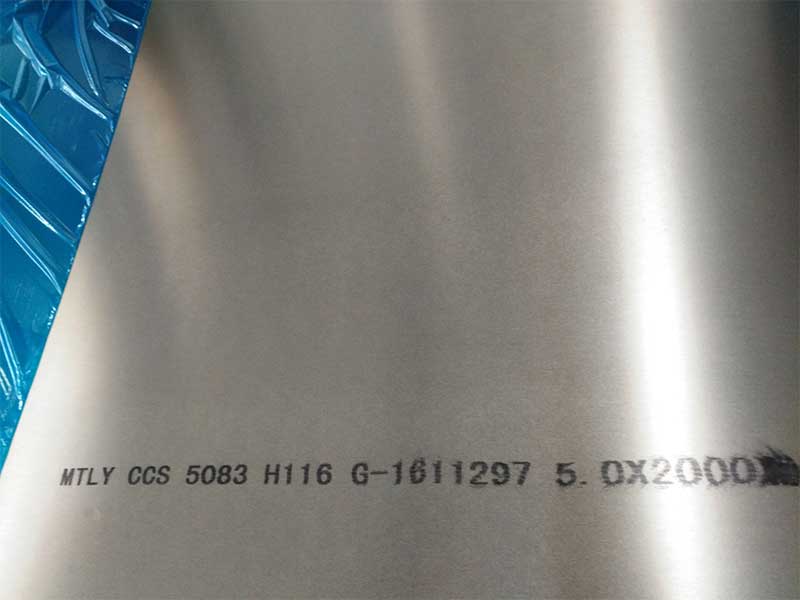

The primary application of marine-grade aluminum coils is in boat construction. Choose 5754 and 5083 grades for hulls, decks, and superstructures due to their high stress resistance and effective corrosion protection. They are commonly used in both commercial and recreational vessels.

2. Shipbuilding

For larger marine vessels, aluminum alloys such as 6061 and 5083 are popular choices. They're used for structural elements that must withstand heavier loads while retaining performance in challenging conditions, making them indispensable in the shipbuilding industry.

3. Marine Equipment

Aluminum coils are also utilized for fabricating various marine equipment, from ladders to fuel tanks. The flexibility in formability allows for the creation of custom designs that fit precise engineering specifications.

4. Infrastructure Applications

In coastal regions, infrastructure like bridges and docks made from marine-grade aluminum coils withstand harsh environmental conditions, significantly extending their lifespan. Alloys like 6063 are particularly useful for architectural elements due to their aesthetic appeal desired in public constructions.

5. Renewable Energy Solutions

Marine-grade aluminum coils are increasingly being used in offshore wind energy projects. Their lightweight and resistant properties make them suitable for supporting rigs, framing, and various structures that can withstand a marine climate.

https://www.al-alloy.com/a/aluminum-coil-marine-grade-6063-6061-5754-5083.html