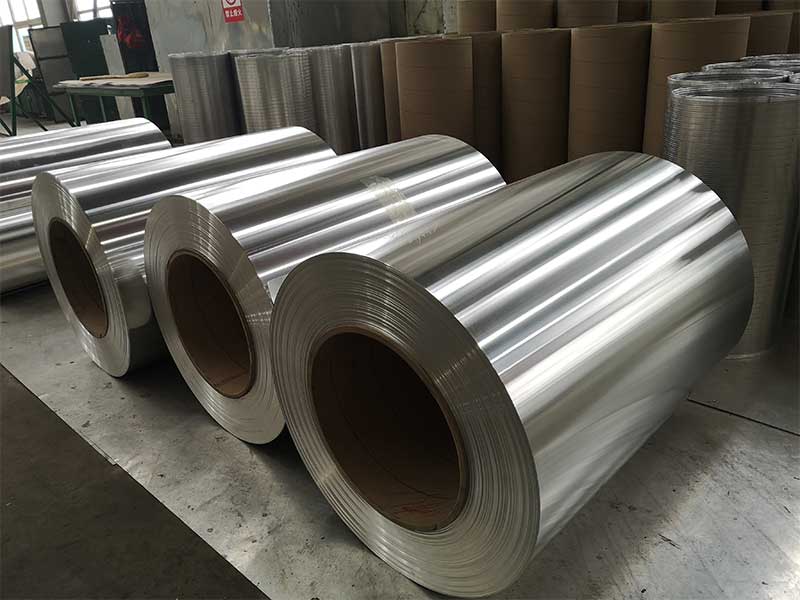

5052 Aluminum Sheet Coil

Article:

When it comes to materials that stand the test of time and use, 5052 aluminum sheet coil is often a top contender in various industries. Known for its exceptional resistance to corrosive environments and remarkable medium to high strength, this alloy is a preferred choice for applications requiring durability. In this article, we delve into the features and applications of 5052 aluminum sheet coils, revealing why they are integral to modern manufacturing.

Unique Features of 5052 Aluminum Sheet Coil

-

Corrosion Resistance: One of the standout features of 5052 aluminum is its remarkable resistance to corrosion, especially in marine and atmospheric environments. This quality makes it ideal for fabrication industries where material stability in varied climates is essential.

-

High Strength-to-Weight Ratio: 5052 aluminum is recognized for its excellent strength combined with lightweight properties. This allows engineers and designers to utilize it in projects where reducing weight without sacrificing strength is crucial.

-

Workability: Due to its advantageous mechanical properties, 5052 aluminum sheet coil is easy to work with and can be subjected to bending, welding, and forming without failure. This makes it a favorite among manufacturers looking for adaptability in the production processes.

-

Formability: 5052 aluminum offers exceptional formability, making it suitable for applications requiring complex designs, tight tolerances, and shapes––in many cases far more complex than other products made from sturdier metals.

-

Surface Treatment Capability: Another unique feature of 5052 aluminum sheet coil is its suitability for undergoing various surface treatments. This means that it can be coated or painted to enhance its aesthetic appeal and protection against environmental impacts.

Diverse Applications of 5052 Aluminum Sheet Coil

The range of applications for 5052 aluminum sheet coils is extensive and varied. Here are some key areas where this alloy consistently performs:

-

Transportation Industry: The high strength-to-weight ratio and excellent resistance to corrosion make 5052 aluminum sheets ideal for marine applications, vehicle body panels, and lightweight construction in automotive design.

-

Manufacturing Boats and Marine Equipment: Due to its aquatic resistance, 5052 is often used in boat building and manufacturing equipment exposed to salty or humid environments, ensuring longevity and structural integrity in watercraft.

-

Medical Equipment: The addition of 5052 aluminum sheets in medical tech offers impressive cleanliness standards as well as strengthened durability essential in tools and movable ramps.

-

Storage Tanks: 5052 aluminum’s corrosion resistance features significantly benefit the fabrication of fuel and chemical storage tanks, crucial for industries dealing with hazardous materials.

-

Architectural Applications: Innovative architects have adopted 5052 aluminum for building exteriors and facades due to its appealing finish and resistance after extended exposure to environmental stressors.