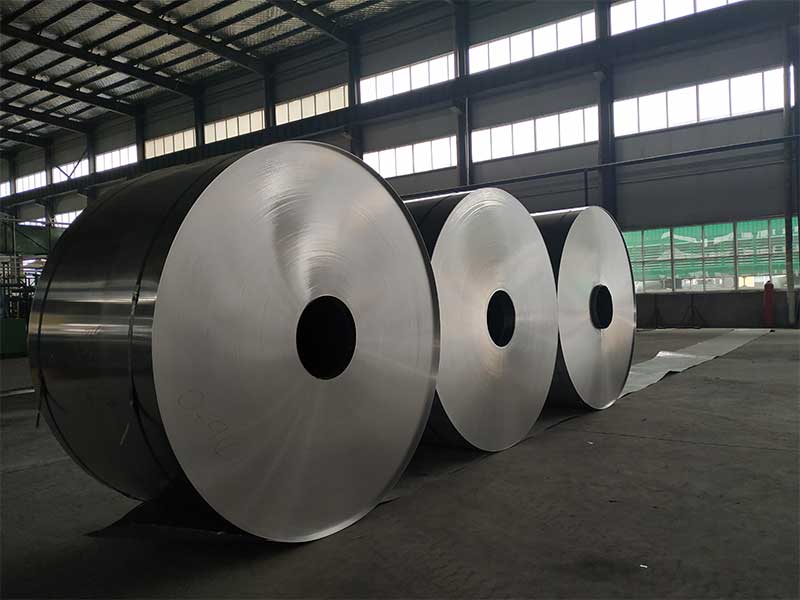

1.2mm 1.5 Mm Thickness Aluminum Coil

Aluminum has long held a diverse range of applications across various industries, from packaging to construction, chiefly due to its favorable properties such as lightweight nature, corrosion resistance, and malleability. Among the myriad of aluminum forms, the 1.2mm and 1.5mm thickness aluminum coils present a specific narrative worth . These aluminum coils offer an intersection of functionality and versatility, making them ideal candidates for a wide spectrum of applications.

Technical Features

At just 1.2mm and 1.5mm in thickness, these aluminum coils exemplify the engineering behind thin materials that maintain structural integrity and performance. Typically derived from AA1060 or AA3003 alloy series—known for their excellent corrosion resistance—the coils showcase a fine mix of lightweight properties that minimize bulk while delivering substantial performance benefits.

Additionally, the coil's mechanical properties coexist beautifully with its thin geometry, as they can withstand significant loading without deforming. High tensile strength combined with excellent workability make these aluminum coils adaptable for multiple fabrication techniques. They readily respond to stamping, bending, and cutting operations due to their ductility.

Heat treatment and annealing increase the anodizing prospects, giving 1.2mm and 1.5mm thickness aluminum coils an appealing Silver or T-Anodize finish. This significantly enhances their surface durability against wear and environmental stressors.

Chemical Considerations

Aluminum's natural anti-corrosive layer elevates its usability; however, the purity of the material does make direct exposure to sodium or chloride-rich conditions worthy of caution. Such environments may lead to pitting, thus highlighting the necessity of specific material treatment protocols for installations in such habitats.

Moreover, adhering to eco-friendly practices, these aluminum coils are readily recyclable, shifting them significantly up the sustainability ladder. Recycling not only decreases resource demand but can considerably minimize the environmental footprint associated with manufacture and obliteration.

Diverse Applications

-

Construction and Building Facades: An integral application of 1.2mm and 1.5mm aluminum coils lies in vertical and horizontal cladding in the construction sector. The lightweight nature aids in satisfying oft-stringent weight regulations on given structures, while the robustness provides competitive lifespan support heretofore featuring heavy alternatives.

-

Automotive Components: Their application extends into manufacturing auto parts such as body panels and heat https://www.al-alloy.com weight reduction complements energy swiftness, enhancing vehicle performance by promoting better fuel efficiency without compromising safety.

-

Electrical Equipment: The liCooling characteristics permit the 1.2mm and 1.5mm coils to aid impoverished electrical conductivity layers played in circuit boards. This results can easily drive safer outcomes by amplifying dissipation issues.

-

HVAC Systems: Utilization within the HVAC framework, especially in designing ductwork, leads to quick installations as these coils offer structural performance combined with pragmatic aesthetics, benefiting both constructers and interior designers.

-

Packaging: As standards rise concerning sustainable packaging materials, the use of these aluminum coils in tube shrank technology adds nutritious characteristics to products—keeping commodities preserved without contaminant transfer.

https://www.al-alloy.com/a/12mm-15-mm-thickness-aluminum-coil.html