1050 h24 mirror polished five circles aluminium tread

the Versatility of 1050 H24 Mirror Polished Five Circles Aluminum Tread

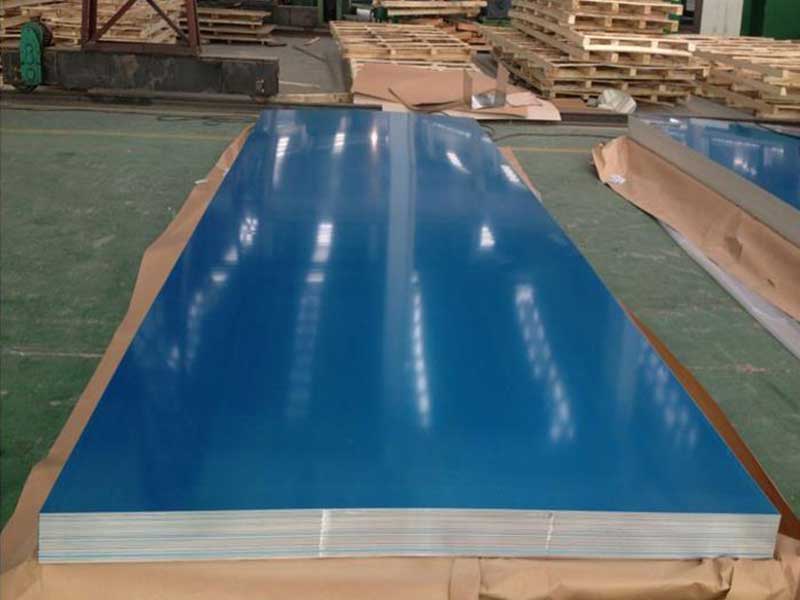

In the realm of structural materials, the spotlight often shines on aluminum due to its unique blend of lightweight strength and corrosion resistance. Within this family, 1050 H24 mirror polished five circles aluminum tread emerges as a standout choice for a variety of applications owing to its durability, aesthetic appeal, and practical functionality.

The 1050 H24 mirror polished five-circle aluminum tread is a fascinating piece of engineering, at least from a production perspective. We use 1050 aluminum alloy for its excellent workability and corrosion resistance – perfect for a product destined for high-traffic areas. Achieving that "mirror polished" finish is demanding; it requires meticulous attention to detail throughout the entire process, from initial rolling to the final polishing stages. Even minor imperfections in the initial sheet can be magnified dramatically during polishing, resulting in rejected pieces. The five-circle pattern itself adds another layer of complexity – precise machining is critical to ensure consistent spacing and depth, and we've had to invest in specialized tooling to maintain quality and speed. We constantly monitor surface roughness using laser scanners to ensure we meet the tight tolerances required for this aesthetically-driven product.

Personally, I find the most interesting aspect is the balance between functionality and aesthetics. While the tread's primary function is to provide safe, non-slip footing, the mirror polish elevates it beyond mere utility. The gleaming surface reflects light in a striking way, transforming what could be a mundane industrial product into something quite visually appealing. This forces us to consider not just the mechanical properties but also the visual impact – ensuring the finish is consistent and free from blemishes across every piece. This push for perfection is something I appreciate, even though it means extra scrutiny and occasional headaches when dealing with particularly challenging batches

1050 H24 Aluminum Alloy

The 1050 H24 alloy signifies a designation within the well-known 1000 series of aluminum alloys, containing at least 99.5% pure aluminum. The ‘H’ in the designation indicates it has been strain-hardened and partially annealed, producing a hardness level that is compatible with various moderate-strength uses. The specific H24 temper showcases a balance between effective hardness and pliability, providing users with an adaptable material for fabrication.

Unique Features of Mirror Polished Five Circles Tread

Thanks to the meticulous mirror polishing process, the five circles aluminum tread plates have a remarkable aesthetic, offering a shiny finish that enhances not only appearance but also hygienic properties due to easy cleaning. This unique five-circle pattern offers improved slip-resistance, making it an indispensable choice in various environments where safety is a priority.

The surface fight against moisture, shows remarkable reflection, and enhances light aesthetics within any given environment. Coupled with the metal's unbeatable lightweight nature and load-bearing capacity, the payoff is significant in multiple fields.

Applications: Where Function Meets Form

The applications of 1050 H24 mirror polished five circles aluminum tread are remarkably diverse.

-

Transportation and Automotive Industries: This aluminum tread plate is often employed as exterior decoration and flooring solutions in executive vehicles, buses, and trucks where aesthetic appeal coupled with durability is paramount. Its lightweight yet tough properties minimize vehicle weight while allowing manufacturers to comply with both performance and energy-saving regulations.

-

Architecture and Construction: Viewed sometimes as the unsung hero of modern architecture, these aluminum tread plates are frequently used on decorative surfaces, wall cladding, and assembly fixtures. Particularly in commercial buildings, its shiny surfaces can create visual presentations while providing structural integrity and resistance to the elements.

-

Food Industry Applications: A significant area where 1050 H24 aluminum tread shines is within the food processing industry. Thanks to its internal properties of easy-cleaning and corrosion resistance, achieving HACCP compliant areas in kitchens and food storage infrastructures becomes easier. Maintaining hygiene is critical in the service industry, and the mirror polish plays a vital role in fulfilling health and food safety standards.

-

Bathrooms and Resort Areas: The incorporation of this alloy also extends to decorative surfaces for bathroom interiors, steam rooms, spa environments, swimming pools, experiencing high-foot-traffic areas. Frequently utilized as flooring and wall panels, the slip-resistance features combine safety with a stunning appearance.

Technical Considerations

-

GSM density (grams per square meter): Typically comes at around 2,700 kg/m3, showcasing feasibility multiplex with high tensile strength parallel to elegant exit produce.

-

Yield Strength: The H24 temper generally presents for corrosion-resistant applications at moderate temperature, conducting energy substitution—suiting logistics handling industrial machinery adaptably.

Leveraging qualities such as recoverable resilience management and interchangeable use, designers and engineers are empowered to expand their creative visions in pristine, robust methods.

https://www.al-alloy.com/a/1050-h24-mirror-polished-five-circles-aluminium-tread.html